PDCA - Free Six Sigma

advertisement

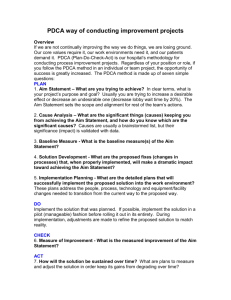

PDCA A Tool For Continuous Improvement 4664-1 Objectives Introduce Lean Six Sigma (LSS) principles Identify the steps of the PDCA problem solving model used in a LSS model Identify and use various quality problem solving tools Identify an use various team dynamic tools Standardize corporate wide PDCA process 4664-2 LSS Yellow Belt A Lean Six Sigma Yellow Belt is an individual who has a broad understanding of LSS and the basic continuous improvement tools Yellow Belts participate on improvement teams as well as use the tools, as applicable, in their day-to-day jobs 4664-3 What is Six Sigma Six Sigma is a business management strategy, originally developed by Motorola, that today enjoys widespread application in many sectors of industry Six Sigma seeks to identify and remove the causes of defects and errors in manufacturing and business processes. Its primary focus is on process targeting and variation reduction It uses a set of quality tools, including statistical methods, and creates a special infrastructure of people within the organization who are experts in these methods Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified financial targets (cost reduction or profit increase) 4664-4 What is Lean Standardized Work “Lean” is a business management strategy, originally called the “Toyota Production System” that was born at Toyota in the early 1950’s Quick Changeover Kanban 5S/ Visual Factory Lean Manufacturing Problem Solving Kaizen Error Proofing Total Productive Maintenance 4664-5 7 Forms of Waste CORRECTION WAITING Repair or Rework Any non-work time waiting for tools, supplies, parts, etc.. OVER PROCESSING Doing more work than is necessary Types of Waste MOTION Any wasted motion to pick up parts or stack parts. Also wasted walking OVERPRODUCTION Producing more than is needed before it is needed INVENTORY TRANSPORTATION Maintaining excess inventory of raw mat’ls, Wasted effort to transport materials, parts, or parts in process, or finished goods into or finished goods. out of storage, or between processes. 4664-6 What is Lean Six Sigma (LSS) Lean Six Sigma is a business management strategy that combines the tools and techniques of Lean Manufacturing and Six Sigma to form an integrated continuous improvement strategy 4664-7 Costs Total Product or Service Price to Customer Profit Profit Total Cost to Produce or Provide 0 A. Budget Constraints and Competition Drive a Lowered Price Profit Waste (COPQ) Theoretical Profit Profit Waste (COPQ) COPQ Costs i.e., Cost of Doing the Right Things Right the First Time B. Theoretical Theoretical Costs Costs C. D. E. 4664-8 What is PDCA Problem Solving Originally developed by Walter Shewhart in 1930s. Sometimes referred as “Shewhart Cycle” Solving problems by finding real root causes Taking action that permanently removes the problem Part of the Continuous Improvement methodology Involves two main strategies Analysis Action 4664-9 PDCA ACT PLAN - Standardize actions - Understand gaps between customer’s expectations and what you deliver - Improve process first by analyzing root causes and identify solutions for these problems - Continue to collect data and verify goals CHECK DO - Observe the effect of the change - Implement solutions using action planning - Collect data to verify changes are working - Collect data to verify goals 4664-10 What is Root Cause Analysis What is Root Cause Analysis? Process to arrive at the preliminary causes of a problem Finding the reason a problem exists and eliminate it with corrective actions Front-end work Defining the problem in quantifiable terms Testing potential root causes Verifying the root cause Common Barriers to Root Cause Analysis Problem described incorrectly Problem solving effort expedited Poor team participation No logical process Permanent corrective action not implemented Over-reliance on experience 4664-11 PDCA Project Status Report PDCA PROJECT STATUS REPORT PROJECT TITLE DATE LOCATION CUSTOMER PLAN DEPARTMENT TEAM LEADER TEAM MEMBERS DEFINE THE PROBLEM IMPLEMENT CONTAINMENT DEFINE THE GOAL ROOT CAUSE ANALYSIS IDENTIFY SOLUTIONS DO IMPLEMENT ACTION PLAN CHECK EVALUATE RESULTS ANALYSIS OF GAPS ACT STANDARDIZE MONITOR RESULTS Page 1 4664-12 Use a Team Approach Starting out right Set meetings, procedures, ground rules Team Membership Who are the other members? Why are they here? What is my role in this team? WIIFM Select a team champion Select team members Select team support Are all areas of technical expertise available? Communications Establish time and resources to work on project 4664-13 Stages of Team Development The stages include: Forming Storming Norming Performing Each stage is unique and each team experiences it in a different way Things are always changing 4664-14 Team Tools: Brainstorming 1. Select a facilitator v Probability of Correct Decision Stre s s or Pre s s ure Force s to the Le ft 2. Give everyone 1-2 minutes to silently think about the problem 3. Invite everyone to contribute ideas 4. Write down all ideas Voting Consensus Leader Rules Minority Majority Rules Rules Don’t critique ideas Use your imagination Build on others’ ideas Piggybacking 5. Continue until you run out of ideas 6. Discuss and narrow down ideas using Nominal Group Technique or Multi-Voting Aim for QUANTITY Record each idea 4664-15 Plan: Define the Problem PLAN Objective: Review existing data Specify the internal/external customer problem by identifying in quantifiable terms (who, what, when, where, why, how, how many) for the problem. DEFINE THE PROBLEM Use an “Operational Definition” that has a common meaning to everyone who reads it Use verifiable criteria Symptoms are often mistakenly used to describe a problem DEFINE THE GOAL ROOT CAUSE ANALYSIS IDENTIFY SOLUTIONS Identify the internal/external customer expectations 4664-16 Plan: Define the Problem Process Review existing data Get team feedback Go see the problem Identify process flow Ask 5W+2H Are there multiple problems? Is containment required Tools Process Mapping 5W+2H Operational Definition Historical Data & Charts Pareto Chart PDCA Project Status Sheet 4664-17 Tools: Flowchart Flowcharting Symbols Process Step Decision Documentation Process Start or Stop Connector Represents functions or steps in the process. A brief description is written in the box. Represents a point where there are at least two alternatives for the next step of the process. A question is written in the diamond. Represents a document that is produced as part of the process. A description is written in the box. Represents the beginning or end of the process. Usually labeled START or END. Used to connect flowcharts between pages or long distances. Usually labeled with a letter or a number. Storage Represents product storage as finished goods or work in progress. Inspection Represents steps where a product is inspected. 4664-18 Tools: Current & Historical Data Customer Feedback PPM charts, SPC/Run charts Program Timelines Test Results Performance Reports/Feedback Input-Process-Output (IPO) 4664-19 Tools: 5W2H Who? Who is the customer complaining? What? What is the complaint or opportunity? When? When did the problem start or occur? Where? Where is the problem observed? Why? Why is this problem occurring (known data)? How? How does the process work? How Many? How many defects? 4664-20 Tools: Pareto Chart 1st Level Pareto 2nd Level Pareto 35 Sources of Application Errors 30 1 = Incorrect Data 2 = Missing Data 3 = Bad Data Entry 4 = Spelling 5 = Penmanship 6 = Other 25 20 30 20 15 10 10 5 5 0 0 2 3 4 5 6 VALUE 1= 2= 3= 4= 5= 6= 25 15 1 Sources of Incorrect Data 35 What is the relative importance of each part of the problems? What should be the starting point for problem solving? Where should we focus our attention? 1 2 3 4 5 6 4664-21 Tools: Operational Definition Description of Problem WHO IS IS NOT Cust omer Name Location WHAT P roduct P rocess System WHEN First Seen When else seen (dates, events) When seen in process life cycle WHERE Seen on object Seen geographically WHY Supportive data HOW P rocess conditions HOW MANY Number of defect Number of parts Number of concerns T rends 4664-22 Tools: Input-Process-Output (IPO) INPUT - PROCESS - OUTPUT (IPO) People Material Perform a Service Equipment Policies Procedures PROCESS (ACTIVITY) Produce a Product Methods Environment Complete a Task SOURCES OF VARIABILITY MEASURES OF PERFORMANCE Process Process Process Process 4664-23 Containment Actions Is Containment Required? Define and implement containment actions to isolate the effect of problem from any internal/external customer until corrective action is implemented Verify the effectiveness of the containment action 4664-24 Containment Actions Minimize effect of problem on the customer Common Problems with Containment Actions Temporary SOP’s Considered as permanent solution 100% sorting/inspection Costly Do/Perform/Make in-house vs outsource Easily forgotten Typically only address an effect and not root cause Same problem/effect will surface again Temporary company policies Additional approvals (signoff) Single source Certified operators/people 4664-25 Tool: Containment Action Worksheet 1. Pos s ible Containment Actions 2. Se le cte dContainment Action(s ) 3. Inte rve ntion in Proce s s /Sys te m : Supplier In -House Customer End User Other: _________________ 4. Ve rification Measure m e nt Measurement Type of Data Collection Chart 5. Validation Me asure m ent Measurement Type of Data Collection Chart 4664-26 Plan: Define the Goal PLAN DEFINE THE PROBLEM Objective: DEFINE THE GOAL Identify “What is the end goal” ROOT CAUSE ANALYSIS IDENTIFY SOLUTIONS 4664-27 Plan: Define the Goal Process Tools Review data Identify goals that are measurable Customer Expectations (Internal/External) Team Tools Does everyone understand? PDCA Project Status Sheet 4664-28 Plan: Root Cause Analysis PLAN Objective: DEFINE THE PROBLEM DEFINE THE GOAL ROOT CAUSE ANALYSIS Identify all potential causes that could explain why the problem occurred Isolate and verify the root cause by testing each potential cause against the problem description IDENTIFY SOLUTIONS 4664-29 Plan: Root Cause Analysis Process Tools Brainstorm additional data requirements Team Tools Repeated Why Analyze data Cause & Effect Diagram Identify potential causes Check Sheets Collect data to isolate root causes SPC and Run Charts Select potential root cause Histogram Prioritize actions Process Flowchart Pareto Chart Scatter Diagram Timeline Root Cause Analysis Worksheet PDCA Project Status Sheet 4664-30 Identify Potential Causes Continue to ask the repeated “Why” statements List potential root causes Group discussion / Brainstorming session Cause and Effect diagram FMEA If the problem is new, develop a time line 4664-31 Tools: Repeated Why Poor Quality Parts Stick to the facts WHY? (Because the) WHY? (Because the) WHY? (Because the) WHY? (Because the) WHY? (Because the) The Problem Statement is……. 4664-32 Tools: Cause and Effect Category Cause Cause Cause Effect Cause Cause & Effect Diagrams are also known as Fishbone Diagrams Category Typical Categories Manpower Machine Methods Material Mother nature (Environment) Measurement 4664-33 Tools: Check Sheet Carmen’s World Famous Whoopie Pies Project: Types of defects in finished pies Defect Data collected by: Dates: June 20-26 Location: Lot size: 200 SUN MON Maine plant TUE WED THU FRI SAT VALUE What facts or data patterns will help us to better understand the problem and its cause(s) ? How do we translate our « opinions » about the problem into « facts » ? Check sheets are used to capture factual data from the beginning. They are filled by operators to describe the situation following the data collection plan. Total Too much cream 24 Too little cream 9 Too crumbly 21 Too big 13 Too small 14 Not sweet enough 9 Not chocolaty enough 1 Has a bite in it 6 4664-34 Tool: Histogram VALUE Frequency How frequently does a certain effect occur? What does the frequency distribution look like - a normal curve or some other statistical form ? How frequently is the process outside of specifications ? What is the nature of the deviation outside of specifications, e.g., synthetically or not,... 18 16 14 12 10 8 6 4 2 0 1 2 3 4 5 6 7 8 9 10 11 Shaft diameter 4664-35 Tools: Histogram Normal Distribution Multi-Modal Distribution Bi-Modal Distribution Positively Skewed Negatively Skewed 4664-36 Tools: Sigma/Distribution Curve 68% 95% 99.7% –3s –2s –1s X +1s +2s +3s 4664-37 Tools: Run Chart Sam ple Run Chart 78 Series1 76 74 72 Value 70 68 66 64 62 60 58 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 Time or Sequence 4664-38 Tools: Sigma/Distribution Curve UCL 3 Sigma 2 Sigma 68% 1 Sigma X 1 Sigma 2 Sigma 95% 3 Sigma 99.7% –3s –2s –1s X LCL +1s +2s +3s 4664-39 Tools: Run Chart / SPC VALUE In the variation we observe in a problem characteristic or parameter, what part is natural variation (within the process Control chart control limits) and what part is due to specific special causes ? random variation vs. special events How often does the process go out of control? Out of control Are there any discernable trends USL that should concern us ? Can any preventive actions be taken based Upper control limit on these trends ? Average Lower control limit LSL Time 4664-40 Tools: Scatter Diagram 4.5 Variable 2 Positive Correlation An increase in y may be related to an increase in x. 4.0 3.5 150 y 400 650 Variable 1 Negative Correlation A decrease in y may be related to an increase in x. 4.0 3.5 150 400 650 Variable 1 Confirm that 2 variables are correlated What is the nature of the relationship between the variables ? x 4.5 Variable 2 VALUE x y 4.5 Variable 2 No Correlation There is no demonstrated connection between y and x. 4.0 3.5 150 400 650 x 4664-41 Tool: Root Cause Analysis Worksheet List of Potential Causes Data Required Responsibility Data Analysis Tools Is this a Root Cause? 4664-42 Plan: Identify Solutions PLAN Objective: DEFINE THE PROBLEM DEFINE THE GOAL Define the best permanent corrective actions Identify measures to ensure the root cause is eliminated ROOT CAUSE ANALYSIS IDENTIFY SOLUTIONS 4664-43 Plan: Identify Solutions Process Tools Identify best solutions Team Tools Verify solutions verses root cause Action Planning Select best solution Force Field Analysis Clearly describe solution Cause & Effect Diagram Determine if simple test is possible Scatter Diagram Verify measurable Decision Matrix Develop Implementation Action Plan Root Cause Solution Worksheet PDCA Project Status Sheet 4664-44 Tools: Action Matrix Big Effect on Root Cause Big Payoff/Easy to do Big Payoff/Hard to do DO THESE NOW! PRIORITIZE/PLAN TO IPLEMENT THESE HARD EASY DO THESE AFTER DOING EVERYTHING ABOVE Minimal Benefit/Easy to do SKIP THESE Minimal Benefit/Hard to do No Effect on Root Cause 4664-45 Tools: Force Field Analysis DRIVERS ISSUE RESTRAINERS 4664-46 Tools: Root Cause Solution Worksheet Root Cause: _____________________________________________________________________________________ List of Potential Solutions Pros / Cons Verification Method Responsibility 4664-47 Do: Implement Action Plan Objective: Implement permanent corrective actions Evaluate results of action plan IMPLEMENT ACTION PLAN 4664-48 Do: Implement Action Plan Process Tools Review action plans Action Planning Worksheet Assign responsibilities Timelines Implement solutions PDCA Project Status Sheet Conduct training Establish controls Verify measurement Remove containment if necessary 4664-49 Tools: Action Planning Worksheet Core Team Member: ______________________________________________________________________________ Actions/Steps Resources Responsibility Start Date Complete Date Validatio n Method Status Comments 4664-50 Check: Evaluate Results Objective: Evaluate Results Verify corrective actions before the actions are permanently implemented Process capability run Quality data analysis Field test Prototype Rework report Document verification results Update quality documents Verify the solution with customer 4664-51 Check: Evaluate Results Process Tools Collect data Quality Charts Analyze data PDCA Project Status Sheet Are results achieved? Has root cause been eliminated? Confirm results with customer Verify no other issues introduced 4664-52 Act: Standardize and Monitor Objective: Validate corrective actions STANDARDIZE & MONITOR Evaluate the effectiveness of current measurements to detect failure Update quality procedures to prevent recurrence of this and all similar problems 4664-53 Act: Standardize and Monitor Process Tools Operating Procedures PDCA Project Status Sheet Identify and agree to long term validation methods Identify similar products, product lines, serviced, equipment, and processes that could benefit from these findings and solutions Update quality documents Retrain as necessary 4664-54 Tool Matrix 4664-55