Kraft Pulping Modeling & Control

advertisement

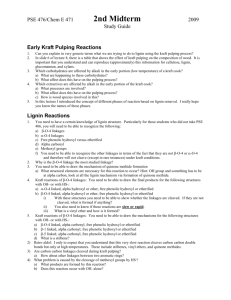

Kraft Pulping Modeling & Control Control of Batch Kraft Digesters 1 Kraft Pulping Modeling & Control H-factor Control Vroom • Manipulate time and/or temperature to reach desired kappa endpoint. • Works well if there are no variations in raw materials or chemicals. Kappa or Yield 15% EA 18% EA 20% EA 2 H-factor Kraft Pulping Modeling & Control H-factor Control Vroom Lignin (% of Pulp) 30 25 150°C 160°C 170°C 20 15 10 5 0 0 500 1000 1500 2000 2500 H Factor 3 Kraft Pulping Modeling & Control Kappa Batch Control Noreus et al. • Control strategy uses empirical model that predicts kappa number from effective alkali concentration of liquor sample at beginning of bulk delignification (~150 ºC). H 2000 n m 1 aij EAi K j H i 0 j 0 K=32 1500 1000 500 EA 12 14 16 18 20 22 24 Necessary H-factor for obtaining K = 32 vs. EA concentration in liquor sample • Where H is H-factor, EA is effective alkali, K is kappa number, and a are model constants. 4 Kraft Pulping Modeling & Control Kappa Batch Sensors • Effective Alkali Analyzer - Conductivity Titration • Temperature and pressure sensors 5 Kraft Pulping Modeling & Control Kappa Batch Laboratory Tests • Effective alkali – compared against titration • End of cook kappa to check prediction 6 Kraft Pulping Modeling & Control Kappa Batch Disturbances/Upsets • Chip Supply » Moisture content, size distribution, chemical content • Pulping Liquor » White liquor EA and sulfidity » Black liquor EA and sulfidity • Digester Temperature Profile » Time to temperature and maximum temperature 7 Kraft Pulping Modeling & Control Kappa Batch Operations and Objectives • Operator Setpoint(s) » End of cook kappa number • Manipulated Variables » Temperature profile » Cooking time • Control Objective » Decrease standard deviation in final kappa target. 8 Kraft Pulping Modeling & Control Kappa Batch Mill Results • Lowered final kappa standard deviation. 9 Kraft Pulping Modeling & Control Kappa Batch Control Benefits • Bleached Pulp » Lower chemical usage and effluent loading in bleach plant • Unbleached Pulp 0.25 » Higher yield Bleached Pulp Unbleached Pulp m = 22 s = 2.0 m = 60 s = 2.0 Frequency 0.20 0.15 m = 25 s = 3.5 0.10 m = 57 s = 3.5 Limit Limit 0.05 0.00 0 10 20 30 40 50 60 70 Kappa 10 80 Kraft Pulping Modeling & Control Batch Control Kerr • Control strategy uses semi-empirical model that predicts kappa number from effective alkali concentration of liquor sample taken at two points in the bulk delignification phase. Li 1 L ln a3 H a 4 b2 L b2 / a2 L f • Where H is H-factor, a2 and b2 are slope and intercept of lignin to EA relationship, a3 and a4 are constants (a3 can incorporate sulfidity and chip 11 properties). Kraft Pulping Modeling & Control Batch Control Kerr 12 Kraft Pulping Modeling & Control Inferential Control Sutinen et al. • Control techniques use liquor measurements (CLA 2000) for control of final kappa number » EA – conductivity » Lignin – UV adsorption » Total dissolved solids – Refractive Index (RI) 13 Kraft Pulping Modeling & Control Inferential Control Sutinen et al. • Statistical model using Partial Least Squares (PLS) to predict kappa number. » Past batch information used to formulate current control model. • Control Strategies » Use PLS model to manipulate cooking time or temperature to achieve final kappa 14 Kraft Pulping Modeling & Control Inferential Control Model Results • Using model final kappa variation reported to be reduced by 50%. 15 Kraft Pulping Modeling & Control Inferential Control Krishnagopalan et al. • Statistical model using Partial Least Squares (PLS) to predict kappa number. » Past batch information used to formulate current control model. • Control Strategies » Direct – Use PLS model to manipulate input vector » Indirect (adaptive) – Use PLS model to estimate parameters of empirical model for control (e.g., Chari, Vroom) • Kinetic models developed for lignin, carbohydrates, and viscosity can be used for optimization (e.g., liquor profiling). 16 Kraft Pulping Modeling & Control Inferential Batch Control Sensors • Continuous in-situ measurements of liquor EA (conductivity), lignin content (UV), solids content (RI), and sulfide concentration (IC). • Measurements are also done using near infrared. 17 Kraft Pulping Modeling & Control Inferential Batch Control Operations and Objectives • Operator Setpoint(s) » End of cook kappa number • Manipulated Variables » Midpoint temperature » Cooking time • Control Objective » Decrease standard deviation in final kappa target 18 Kraft Pulping Modeling & Control Inferential Batch Control Operations and Objectives • Model based control adjusts both end time and temperature in optimal fashion. • Temperature main manipulated variable 180 170 160 150 Temp (°C) 140 130 120 110 100 90 80 0 20 40 60 80 100 Tim e (m in) 120 140 160 180 200 19 Kraft Pulping Modeling & Control Inferential Batch Control Simulated Results • Adaptive strategy performs better. Handles nonlinearity between manipulated variables and end kappa more efficiently. 20