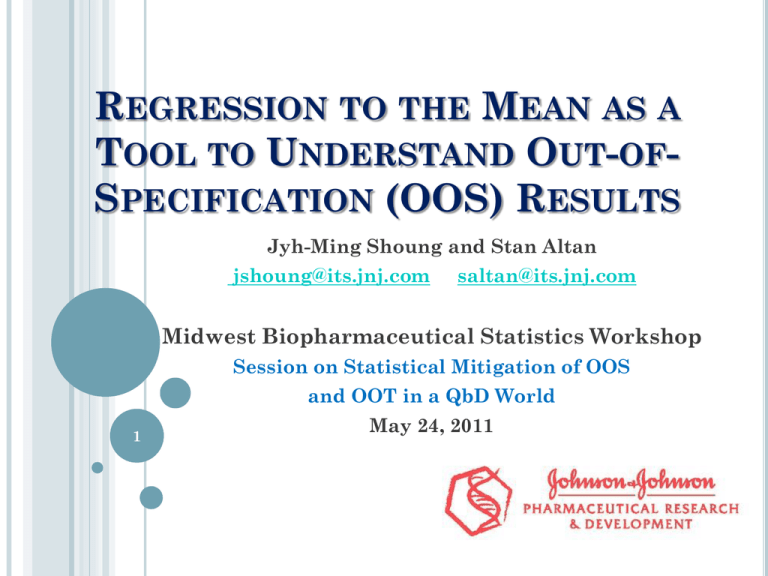

Regression to the Mean as a Tool to Understand Out

advertisement

REGRESSION TO THE MEAN AS A TOOL TO UNDERSTAND OUT-OFSPECIFICATION (OOS) RESULTS Jyh-Ming Shoung and Stan Altan jshoung@its.jnj.com saltan@its.jnj.com Midwest Biopharmaceutical Statistics Workshop Session on Statistical Mitigation of OOS and OOT in a QbD World 1 May 24, 2011 OUTLINE o Introduction o o o OOS Guidance for Industry (October 2006) – the current regulatory view Out-of-Specification (OOS) results viewed through the prism of Regression to the Mean(RtM) OOS Case Study – applying RtM principles Recommendations 2 INTRODUCTION THE CURRENT REGULATORY VIEW OOS Guidance for Industry (October 2006) Prescriptive approach to investigations addressing the question of root cause Is there a flaw in the product or process? Statistical references ; Outlier testing - write it into the SOP It should never be assumed that the reason for an outlier is error in the testing procedure, rather than inherent variability in the sample being tested. Retesting (of the original sample) The number of retests to be performed on a sample should be specified in advance by the firm in the SOP…based on scientifically sound, supportable principles. The number should not be adjusted depending on the results obtained. Re-sampling (new sample) appears to be discouraged, the original sample is supposed to be large enough to permit retesting 3 OOS GUIDANCE – WHAT IS THE ISSUE? o Ignores statistical considerations o o “In cases where … some of the individual results are OOS, some are within specification, ... the passing results are no more likely to represent the true value for the sample than the OOS results…and treat the reportable average of these values as an OOS result, even if that average is within specification. … every individual application of the official test should be expected to produce a result that meets specifications.” This language is in conflict with the basic principle that the essential quality statement is captured in the ‘average’ and variability between dose units is captured in a separate protocol An operational root cause will not be found for some or many OOSs, and this does not necessarily indicate a product or process flaw 4 QUALITY BY DESIGN –AN OPPORTUNITY TO REVISIT OOS MANAGEMENT? o Improved Process Knowledge Systematic Development approach Formulation understanding Process understanding Packaging understanding o o o Identify Critical to Quality Attributes (CQAs) Process Understanding as input to risk management - Quality risk management Control what is critical - Advanced control strategy 5 A PROCESS IS WELL UNDERSTOOD WHEN… o All critical sources of variability are identified and explained OOSs o WILL happen occasionally Variability is managed by the process How do we integrate occurrence of OOS’s in a QbD framework o Product quality attributes can be accurately and reliably predicted over the design space Basic Principle : Occurrence of isolated OOSs does not contradict quality in product manufacture 6 Tim Schofield (Specs Workshop, 2005) o o o Multiple repeated stability determinations of the same lot on stability necessarily lead to an increasing chance of an OOS Such OOSs require context and mitigation Statistical mitigation is completely consistent with QbD concepts of advanced risk management and control strategies 7 OOS’S VIEWED THROUGH THE PRISM OF REGRESSION TO THE MEAN IN A QbD CONTEXT o o o o An isolated OOS can be thought of as a random outcome related to incipient sources of variability and hence should be viewed as a normal part of data collection and testing Compliance considerations have clouded the true understanding of the occurrence of OOSs Under QbD, control strategies related to statistical considerations can be brought to bear to understand and assess the ‘truth’ of an OOS OOSs can be mitigated through the application of a Regression to the Mean approach 8 REGRESSION TO THE MEAN (RtM) Regression to the Mean (RtM) is a statistical phenomenon that occurs when repeated measurements are made on the same subject or unit of observation. http://www.socialresearchmethods.net/kb/regrmean.php During development studies or commercial studies where numerous analytical determinations are being carried out on the same batch or process, isolated unusual observations can be expected and understood as a ‘pretest’ to be mitigated through a 9 ‘posttest’. CASE STUDY OF A RTM EXAMPLE IN RELEASE TESTING OF CONTENT UNIFORMITY AND HOW IT CAN BE APPLIED TO AN ADVANCED 10 CONTROL STRATEGY HARMONIZED CONTENT UNIFORMITY TEST - USP <905> (JANUARY, 2007) Stage 1, 10 Tablets | M X | k s 15, k 2.4 Noneout side (0.75M,1.25M) M X if 98.5 X 101.5 No Stage 2, additional 20 Tablets M 98.5 if X 98.5 M 101.5 if X 101.5 Yes PASS | M X | k s 15, k 2.0 Noneout side (0.75M,1.25M) M X if 98.5 X 101.5 No FAIL M 98.5 if X 98.5 M 101.5 if X 101.5 Yes PASS 11 DATA DESCRIPTION AND GOAL o Data 2,000 marketed lots from 12 different groups of sizes New USP test criteria applied to all 2000 lots o 1,997 lots passed new USP test <905>, 3 lots failed (X, Y, Z) Stage 1, Stage 2 not available Issue o Manufactured prior to 2007 and tested under old USP method 6 lots (A – F) with Stage 2 CU data Lots (X, Y, Z) failed new Stage 1 test and no Stage 2 data Objective Predict Stage 2 test likely outcome based on a RtM analysis 12 STAGE 2 RtM TRAJECTORIES IN 6 LOTS S2 (n=30) test criteria 3 lots without S2 samples S1 (n=10) test criteria 13 MODEL ASSUMPTIONS AND FIT RESULTS o o o 2,000 lots with Stage 1 and Stage 2 (only 6 lots) data were used for analysis A mixed effects model was fit to the data with fixed effects for group and random effects due to lot-to-lot within group, stage-to-stage test (analytical run-to-run) within lot and residuals (dose unit, measurement error, etc.) The estimated variance components are as follows: ( b2 ) = 2.8 Var(Lot) Var(Stage) (2 ) = 7.1 Var(Resid) (w2 ) = 3.8 14 MULTIVARIATE NORMAL DISTRIBUTION Considering the following two equations X 1 b 1 w1 X 2i b 2 w2i , i 1,,20 where b , 1 , 2, w1 , w2i are independent and b Norm al( 0 , ) , 1 Norm al( 0 , ) 2 b 2 2 Norm al( 0 , 2 ) , w1 Norm al( 0 , w2 /10 ) and w2i Norm al( 0 , w2 ). 15 THEORETICAL RTM EFFECT Given X 1 x1 , X 2i | X 1 x1 ( b 2 w2i ) | X 1 x1 ( b | X 1 x1 ) 2 w2i And the conditional distribution of +b given X 1 x1 is 2 b | X 1 x1 Norm al ( x1 ) , 22 (1 2 ) 1 where / 10 , , and 2 1 2 b 2 2 w 2 2 2 b b2 12 22 16 SIMULATION OF USP STAGE 2 TEST - ADDITIONAL 20 SAMPLES GIVEN STAGE 1 MEAN 2 Norm al ( x1 ) , 22 (1 2 ) 1 Adding variability due to stage-to-stage Normal 0 , 2 Adding 20 residual errors Norm al(0, w2 )1 , Norm al(0, w2 ) 2 , Norm al(0, w2 ) 20 2 E ( X 2 | X 1 x1 ) ( x1 ) 1 RtM Effect 17 EMPIRICAL RTM EFFECT The empirical RtM effect can be estimated by a linear regression of second stage mean (n=20) on the first stage mean (n=10) from those 6 lots with stage 2 results as follows: Obs.S2mean – Group Mean = × (Obs.S1mean – Group Mean) + error 18 X 2( n20) vs. X 1( n10) Theoretical RtM Empirical RtM 19 10,000 SIMULATED S2 RESULTS LOT A Observed S1 result (n=10) Observed S2 result (n=30) Simulated S2 results (n=30) 20 21 SUMMARY RESULTS Statistical evaluation of 3 lots reporting outlying Stage 1 results shows that on simulated retest, all 3 would pass Stage 2 criterion (> 99%) as a consequence of Regression to the Mean Principle with high certainty Caveat : Limited information to estimate RTM effect but justified by the overwhelmingly stable behavior of the process This case study shows the application of the RtM principle to OOS mitigation 22 RECOMMENDATIONS AND FUTURE RESEARCH o o o o o As a consequence of the Clinical Drug Development paradigm, Quality of Materials should be related to the Average as the essential quality statement Content uniformity should not be inferred from isolated indeterminate OOSs Re-sampling should be part of a control strategy to mitigate OOS and exploit the RtM principle to achieve a more representative sample for calculating the lot Average The RtM principle can serve as a basis for pursuing advanced control strategies for OOS mitigation Directions for future research Bayesian approach – in a commercial context could be easier to justify priors Errors-in-variable adjustment 23