The Randomized Complete Block Design

advertisement

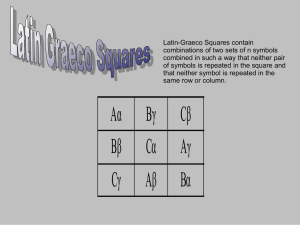

Design and Analysis of Experiments Dr. Tai-Yue Wang Department of Industrial and Information Management National Cheng Kung University Tainan, TAIWAN, ROC 1/33 Experiments with Blocking Factors Dr. Tai-Yue Wang Department of Industrial and Information Management National Cheng Kung University Tainan, TAIWAN, ROC 2/33 Outline The Randomized Complete Block Design The Latin Square Design The Graeco-Latin Square Design Balanced Incomplete Block Design 3/33 The Randomized Complete Block Design In some experiment, the variability may arise from factors that we are not interested in. A nuisance factor (擾亂因子)is a factor that probably has some effect on the response, but it’s of no interest to the experimenter … however, the variability it transmits to the response needs to be minimized These nuisance factor could be unknown and uncontrolled use randomization 4 The Randomized Complete Block Design If the nuisance factor are known but uncontrollable use the analysis of covariance. If the nuisance factor are known but controllable use the blocking technique Typical nuisance factors include batches of raw material, operators, pieces of test equipment, time (shifts, days, etc.), different experimental units 5 The Randomized Complete Block Design Many industrial experiments involve blocking (or should) Failure to block is a common flaw in designing an experiment (consequences?) 6 The Randomized Complete Block Design-example We wish determine whether or not four different tips produce different readings on a hardness testing machine. One factor to be consider tip type Completely Randomized Design could be used with one potential problem the testing block could be different The experiment error could include both the random and coupon errors. 7 The Randomized Complete Block Design-example To reduce the error from testing coupon, randomize complete block design(RCBD) is used 8 The Randomized Complete Block Design-example Each coupon is called a “block”; that is, it’s a more homogenous experimental unit on which to test the tips “complete” indicates each testing coupon (BLOCK) contains all treatments Variability between blocks can be large, variability within a block should be relatively small In general, a block is a specific level of the nuisance factor 9 The Randomized Complete Block Design-example A complete replicate of the basic experiment is conducted in each block A block represents a restriction on randomization All runs within a block are randomized Once again, we are interested in testing the equality of treatment means, but now we have to remove the variability associated with the nuisance factor (the blocks) 10 The Randomized Complete Block Design– Extension from ANOVA Suppose that there are a treatments (factor levels) and b blocks 11 The Randomized Complete Block Design– Extension from ANOVA Suppose that there are a treatments (factor levels) and b blocks i 1, 2,..., a yij i j ij j 1, 2,..., b H 0 : 1 2 a where i (1/ b) j 1 ( i j ) i b 12 The Randomized Complete Block Design– Extension from ANOVA A statistical model (effects model) for the RCBD is i 1, 2,..., a yij i j ij j 1, 2,..., b The relevant (fixed effects) hypotheses are H 0 : 1 2 a where i (1/ b) j 1 ( i j ) i b H1 : at least one i j 13 The Randomized Complete Block Design– Extension from ANOVA Or H 0 : 1 2 a 0 H1 : at least one i 0 14 The Randomized Complete Block Design– Extension from ANOVA Partitioning the total variability a b a b 2 ( y y ) ij .. [( yi. y.. ) ( y. j y.. ) i 1 j 1 i 1 j 1 ( yij yi. y. j y.. )]2 a b i 1 j 1 b ( yi. y.. ) 2 a ( y. j y.. ) 2 a b ( yij yi. y. j y.. ) 2 i 1 j 1 SST SSTreatments SS Blocks SS E 15 The Randomized Complete Block Design– Extension from ANOVA The degrees of freedom for the sums of squares in SST SSTreatments SS Blocks SS E are as follows: ab 1 a 1 b 1 (a 1)(b 1) Therefore, ratios of sums of squares to their degrees of freedom result in mean squares and the ratio of the mean square for treatments to the error mean square is an F statistic that can be used to test the hypothesis of equal treatment means 16 The Randomized Complete Block Design– Extension from ANOVA Mean squares a E MStreatment 2 b i2 i 1 a 1 a E MSBlock 2 E MSE 2 a j2 i 1 b 1 17 The Randomized Complete Block Design– Extension from ANOVA F-test with (a-1), (a-1)(b-1) degree of freedom MSTreatments F0 MSE Reject the null hypothesis if F0>F α,a-1,(a-1)(b-1) 18 The Randomized Complete Block Design– Extension from ANOVA ANOVA Table 19 The Randomized Complete Block Design– Extension from ANOVA Manual computing: 20 The Randomized Complete Block Design– Extension from ANOVA Meaning of F0=MSBlocks/MSE? The randomization in RBCD is applied only to treatment within blocks The Block represents a restriction on randomization Two kinds of controversial theories 21 The Randomized Complete Block Design– Extension from ANOVA Meaning of F0=MSBlocks/MSE? General practice, the block factor has a large effect and the noise reduction obtained by blocking was probably helpful in improving the precision of the comparison of treatment means if the ration is large 22 The Randomized Complete Block Design– Example 23 The Randomized Complete Block Design– Example To conduct this experiment as a RCBD, assign all 4 pressures to each of the 6 batches of resin Each batch of resin is called a “block”; that is, it’s a more homogenous experimental unit on which to test the extrusion pressures 24 Vascular-Graft.MTW The Randomized Complete Block Design– Example—Minitab StatANOVATwo-way Two-way ANOVA: Yield versus Pressure, Batch Source DF SS MS F P Pressure 3 178.171 59.3904 8.11 0.002 Batch 5 192.252 38.4504 5.25 0.006 Error 15 109.886 7.3258 Total 23 480.310 S = 2.707 R-Sq = 77.12% R-Sq(adj) = 64.92% 25 Vascular-Graft.MTW The Randomized Complete Block Design– Example—Minitab 26 The Randomized Complete Block Design– Example —Residual Analysis Basic residual plots indicate that normality, constant variance assumptions are satisfied No obvious problems with randomization No patterns in the residuals vs. block Can also plot residuals versus the pressure (residuals by factor) These plots provide more information about the constant variance assumption, possible outliers 27 Vascular-Graft.MTW The Randomized Complete Block Design– Example—Minitab 28 Vascular-Graft.MTW The Randomized Complete Block Design– Example —No Blocking StatANOVAOne-way One-way ANOVA: Yield versus Pressure Source DF SS MS F P Pressure 3 178.2 59.4 3.93 0.023 Error 20 302.1 15.1 Total 23 480.3 S = 3.887 R-Sq = 37.10% R-Sq(adj) = 27.66% 29 Vascular-Graft.MTW The Randomized Complete Block Design– Example—No Blocking-Residual 30 The Randomized Complete Block Design– Other Example 化學品 類 別 1 2 3 4 y. j 1 1.3 2.2 1.8 3.9 9.2 y. j 2.30 2 1.6 2.4 1.7 4.4 10.1 樣品 3 0.5 0.4 0.6 2.0 3.5 4 1.2 2.0 1.5 4.1 8.8 5 1.1 1.8 1.3 3.4 7.6 yi. 5.7 8.8 6.9 17.8 39.2 yi. 1.14 1.76 1.38 3.56 1.96 2.53 0.88 2.20 1.90 y.. y.. 31 The Randomized Complete Block Design– Other Example 4 5 SST i 1 j 1 yij2 y..2 ab ( 39 .2 )2 ( 1.3 ) ( 16 . ) ( 3.4 ) 25.69 20 2 2 2 yi2. y..2 ab i 1 b a SS Factors ( 57 . )2 ( 8 .8 )2 ( 6 .9 )2 ( 17 .8 )2 ( 39 .2 )2 18 .04 5 20 SS Blocks y.2j y..2 ab j 1 a b ( 9 .2 )2 ( 10 .1 )2 ( 3.5 )2 ( 8 .8 )2 (7 .6 )2 ( 39 .2 )2 6 .69 4 20 SS E SST SS Blocks SS Factors 0.96 32 The Randomized Complete Block Design– Other Example Blocking effect Two-way ANOVA: 濃度 versus 化學品類別, 樣品 Source DF 化學品類別 3 樣品 4 Error 12 Total 19 SS MS F P 18.044 6.01467 75.89 0.000 6.693 1.67325 21.11 0.000 0.951 0.07925 25.688 S = 0.2815 R-Sq = 96.30% R-Sq(adj) = 94.14% Without blocking effect One-way ANOVA: 濃度 versus 化學品類別 Source DF SS MS F P 化學品類別 3 18.044 6.015 12.59 0.000 Error 16 7.644 0.478 Total 19 25.688 S = 0.6912 R-Sq = 70.24% R-Sq(adj) = 64.66% The Randomized Complete Block Design– Other Example Blocking effect Source of Variation Sum of Squares 自由度 變異數 MS 6.01 化學品 18.04 df 3 集區 6.69 4 1.67 誤差 0.96 12 0.08 總和 25.69 19 F0 75.13 Without blocking effect Source of 自由度 變異數 Variation Sum of Squares df MS 18.04 3 6.01 化學品 誤差 7.65 16 總和 25.69 19 0.48 F0 12.59 The Randomized Complete Block Design– Other Aspects The RCBD utilizes an additive model – no interaction between treatments and blocks i 1, 2,..., a yij i j ij j 1, 2,..., b Treatments and/or blocks as random effects Missing values What are the consequences of not blocking if we should have? The Randomized Complete Block Design– Other Aspects Sample sizing in the RCBD? The OC curve approach can be used to determine the number of blocks to run..see page 133 i 1, 2,..., a yij i j ij j 1, 2,..., b The Latin Square Design These designs are used to simultaneously control (or eliminate) two sources of nuisance variability Those two sources of nuisance factors have exactly same levels of factor to be considered A significant assumption is that the three factors (treatments, nuisance factors) do not interact If this assumption is violated, the Latin square design will not produce valid results Latin squares are not used as much as the RCBD in industrial experimentation 37 The Latin Square Design The Latin square design systematically allows blocking in two directions In general, a Latin square for p factors is a square containing p rows and p columns. Each cell contain one and only one of p letters that represent the treatments. 38 A Latin Square Design – The Rocket Propellant This is a 5 5 Latin square design 39 Statistical Analysis of the Latin Square Design The statistical (effects) model is i 1, 2,..., p yijk i j k ijk j 1, 2,..., p k 1, 2,..., p The statistical analysis (ANOVA) is much like the analysis for the RCBD. 40 Statistical Analysis of the Latin Square Design 41 Statistical Analysis of the Latin Square Design 42 The Standard Latin Square Design A square with first row and column in alphabetical order. 43 Other Topics Missing values in blocked designs RCBD Latin square Estimated by yijk p( yi'.. y.' j. y..' k ) 2 y...' ( p 1)( p 1) 44 Other Topics Replication of Latin Squares To increase the error degrees of freedom Three methods 1. Use the same batches and operators in each replicate 2. Use the same batches but different operators in each replicate 3. Use different batches and different operator 45 Other Topics Replication of Latin Squares ANOVA in Case 1 46 Other Topics Replication of Latin Squares ANOVA n Case 2 47 Other Topics Replication of Latin Squares ANOVA n Case 3 48 Other Topics Crossover design p treatments to be tested in p time periods using np experiment units. Ex : 20 subjects to be assigned to two periods First half of the subjects are assigned to period 1 (in random) and the other half are assigned to period 2. 49 Take turn after experiments are done. Other Topics Crossover design ANOVA 50 Graeco-Latin Square For a pxp Latin square, one can superimpose a second pxp Latin square that treatments are denoted by Greek letters. 51 Graeco-Latin Square If the two squares have the property that each Greek letter appears once and only once with each Latin letter, the two Latin squares are to be orthogonal and this design is named as Graeco-Latin Square. It can control three sources of extraneous variability. 52 Graeco-Latin Square ANOVA 53 Graeco-Latin Square --Example In the rocket propellant problem, batch of material, operators, and test assemblies are important. If 5 of them are considered, a Graeco-Latn square can be used. 54 Graeco-Latin Square --Example 55 Graeco-Latin Square --Example 56