ME 322: Instrumentation Lecture 6

advertisement

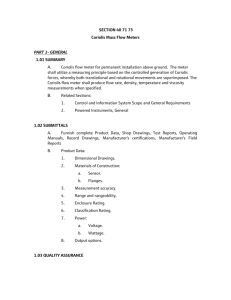

ME 322: Instrumentation Lecture 6 January 30, 2015 Professor Miles Greiner Review Calibration, Lab 3 Calculations, Plots and Tables Announcements/Reminders • HW 2 due Monday – L3PP – Lab 3 preparation problem • Create an Excel Spreadsheet to complete the tables, plots and question in the Lab 3 instructions, using the sample data on the Lab 3 website. • Bring that spreadsheet to lab next week and use it for your data. • You can sign up for Extra credit Science Olympiad until Wed, Feb 4, 2015 • HW 1 Comments – Plot using Excel (not by hand) – Hint: Do some summation calculations by hand to be sure you know how it is done Instrument Calibration (review) • Measure instrument output (R) for a range of known measurands (M, as measured by a reliable standard) • Perform measurements for at least one cycle of ascending and descending measurands • Fit an algebraic equation to the R vs M data to get instrument transfer function: – Linear: R = aM + b – Other: i.e. R = aM2 + bM + c, or … • Find standard error of the estimate of R given M, sR,M – 𝑠𝑦,𝑥 = 𝑛 (𝑦 −𝑎𝑥 −𝑏)2 𝑖 𝑖=1 𝑖 𝑛−2 – This assumes the deviations are the same for all values of M How to Use the Calibration • Invert transfer function – If linear: M = (R-b)/a • Find standard error of the estimate of M given R – sM,R = sR,M/a • For a given reading 𝑅 – The best estimate of the measurand is • 𝑀 = (𝑅 − 𝑏)/𝑎 – The best statements of the confidence interval are • M = 𝑀 + sM,R units (68%), or • M = 𝑀 + 2sM,R units (95%), or … What does Calibration do? • Removes systematic bias (calibration) error • Quantifies random errors – imprecision, non-repeatability errors – But does not remove them • Quantifies user’s level of confidence in the instrument Manufacturers often state “accuracy” • May include both imprecision and calibration drift – Often not clearly defined • This is one of the objectives of Lab 3 Table 1 Equipment Specifications Model 616-5 Model 616-1 Transmitter 40 inch-WC 3 inch-WC Full Scale Range ±0.25% FS ±0.25% FS Relative Accuracy ±0.1 inch-H2O ±0.0075 inch-H2O Absolute Accuracy Manufacturer's Inverted h = (3 inch-H2O)(I T-4mA)/16mA h = (40 inch-H2O)(IT-4mA)/16mA Transfer Function Pressure Standard 25 mBar (10 in-WC) 350 mBar (141 in-WC) Full Scale Range ±0.035% FS ±0.1% FS Relative Accuracy ±0.05 inch-H2O ±0.01 inch-H2O Absolute Accuracy • In your report you will use the first column, and only one from the second and third columns • The confidence levels for the transmitter accuracy is not given by the manufacturer – We will determine it in this experiment. Standard Reading, hS [in WC] Transmitter Output, IT [mA] 0 0.5328 1.0597 1.5617 2.0863 2.5295 1.9637 1.5483 0.9211 0.5216 0 0.5619 0.9595 1.4562 1.9927 2.6214 2.1092 1.6423 1.0696 0.5315 0 4 6.88 9.72 12.48 15.34 17.83 14.66 12.35 9.03 6.83 4.01 7.09 9.18 11.92 14.84 18.3 15.43 12.89 9.86 6.88 4.02 Table 2 Calibration Data • This table shows two cycles of ascending and descending pressure calibration data. • The transmitter current did not return to 4.00 mA at the end of the descending cycles. Fig. 1 Measured Transfer Function • For the sample data – The measured transmitter current is consistently higher than that predicted by the manufacturerspecified transfer function. – Standard errors of the estimates for the transmitter current for a given pressure heat is SI,h = 0.035 mA, and Sh,I = 0.0065 in-WC. – The manufacturer-stated accuracy (0.0075 in-WC) for the transmitter is 1.15 times larger than Sh,I, corresponding to a 75% confidence level. • Your data may be different! Fig. 2 Error in Manufacturer’s Transfer Function • Error in the manufacturer-specified transfer function increases with pressure • Maximum error magnitude is 0.35 mA. Fig. 3 Deviation from Linear Fit • SI,h characterizes the deviations over the full range of hS • Neither the ascending nor the deviations are generally positive or negative, which suggests that hysteresis does not play a strong role in these measurements. • There are no systematic deviations form the fit correlation, indicating the instrument response is essentially linear. This lecture demonstrates how to • Format plot labels, borders, fonts,.. – Different symbols for ascending and descending data • Calculate standard error of estimate, confidence level • Write abstract last: Objective, methods, results • Sample Data • http://wolfweb.unr.edu/homepage/greiner/teaching/MECH3 22Instrumentation/Labs/Lab%2003%20PressureCalibration /Lab%20Index.htm Confidence Level of Manufacture-Stated Uncertainty • Find the probability a measurement is within 1.15 standard deviations of the mean • Identify: Symmetric problem • z1 = -1.15, z2 = 1.15 𝑃 −1.15 < 𝑧 < 1.15 = 𝐼 1.15 − 𝐼 −1.15 = 𝐼 1.15 − −𝐼 1.15 = 2𝐼 1.15 = 2 0.3749 = 75% • Your confidence level may be different Interpretation of Measurement Question Transmitter Output, IT 10.73 mA Inverted Measured Transfer Function h = (0.1838 inWC/mA)IT - 0.7342 inWC Standard Error of the Estimate of Pressure Head for a Given Current, S h,I 68% Confidence Interval Inverted Manufacturer's Transfer Function Confidence Interval if not Calibrated (Unknown confidence Level) 0.0065 in WC 1.2380 ± 0.0065 in WC h = (0.1875 inWC/mA)IT - 0.75 inWC 1.2619 ± 0.0075 inWC Abstract • In this lab, a 3-inch-WC pressure transmitter was calibrated using a pressure standard. – The transmitter current IT was measured for a range of pressure heads h, as measured by a pressure standard. • The measured inverted-transfer-function was – h = (0.1838 in-WC/mA)IT – (0.7335 in-WC), – The 68%-confidence-level confidence-interval for this function is ± 0.0064 in-WC • The manufacturer’s stated uncertainty is 0.0075 in-WC – This is 1.15 time larger than the 68%-confidence-level interval, which corresponds to a 75%-confidence-level Lab 3 Static Calibration of Electronic Pressure Transmitters February 3, 2014 Group 0 Miles Greiner Lab Instructors: Josh McGuire, Şevki Çeşmeci, and Roberto Bejarano Sxy= Standard error in X given Y Syx Sxy Example of Hysteresis