Milk - Marblehead High School

advertisement

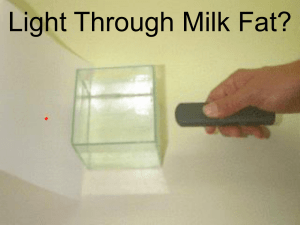

Milk Trends Fluid milk and cream consumption has declined steadily reaching a record low of 200.5 lb in 2005. In 1970, fluid milk and cream consumption was 275 lb. There has been a trend to less consumption of whole milk products to more consumption of lower fat milk products. Frozen dairy products, such as ice cream have been declining since about 1994. Gross Composition % by weight Component Cow Water 87.3 Lactose 4.8 Fat 3.7 Protein 3.4 Salts(minerals) 0.7 Nutrients Milk contains many nutrients: protein, lactose, fats, vitamins, minerals, and enzymes Milk is a complex physiochemical system. It has particles in: 1. True solution - sugar and salt 2. Colloidal dispersion - protein 3. Globules - fat Protein Casein - 80% of total milk protein. Casein is a phosphoprotein containing phosphoric acid. – Coagulates to form a gel – Coagulates at pH 4.6 – Coagulates at high pH (6.5) with rennet – Several types of casein - alpha, beta, gamma, kappa Whey protein – 20% of total milk protein – Do not coagulate at pH 4.6 – Do not coagulate with rennet Proteins – Lactalbumin - 8% of protein (N) Water soluble and forms flucculent precipitate that settles on bottom and sides of pan when heated. – Lactoglobulin - 3.5% of protein (N) Insoluble in water but soluble in dilute neutral salts. Precipitated by heat. – Serum albumin and immunoglobulin Fat Exists as large globules varying in size from 0.1-10um in diameter. Mostly (>95% triglycerides) Triglycerides = glycerol + fatty acids Milkfat contains high proportion of short chain fatty acids (C4-C10) Butyric acid (C4) is unique to milkfat Responsible for flavors and aroma when acted by enzyme lipase. Carbohydrate (Lactose) Milk contains lactose or milk sugar. Lactose = glucose + galactose Some people exhibit lactose intolerance and thus milk may give cramping and diarrhea Principle source of energy for lactic acid bacteria. Bacteria converts lactose to lactic acid (cheese, yogurt, cultured milk, sour cream) Vitamins B1 - thiamine B2 - riboflavin B6 - pyridoxine B12 - cyanocobalamin niacin pantothenic acid Vitamin A, D, E and K (Fat soluble vitamins) Minerals and Enzymes Calcium Phosphorus Low in copper and iron Low levels of sodium, chloride, Magnesium Plasmin Lipase Milk is well buffered by protein and salts especially phosphates Pasteurization Low temperature holding (LTH) - 63 C or 145 F for 30 min. High temperature short time (HTST) 72 C or 162 F for 15 sec. Ultrapasteurization - 138 C or 280 F for 2 or more sec. Ultra high temperature (UHT) - 138-150C or 280-302 F for 2-6 sec. Homogenization Homogenization Mechanical treatment of the fat globules in milk brought about by passing milk under high pressure through a tiny orifice Decrease in the average diameter and an increase in number and surface area Reduced tendency for creaming of fat globules Enhanced stability of homogenized milk Types of Milk Fluid 1. Whole - 3.25% butterfat 2. Low-fat - 2% or 1% butterfat 3. Skim or nonfat - fat-free 4. Lactose-free-treated with lactase to form glucose and galactose Canned 1. Evaporated - 60% water removed by heat 2. Sweetened condensed - sugar added and 1/3 water removed Dried 1. Spray dried - 2/3 water removed by vacuum, them sprayed into chamber of hot air. 2. Foam spray dried - spraying a jet of hot air into concentrated skim milk. 3. Instant - agglomerated, porous particles take up liquid quickly. Filled milks - fat other than milkfat, water, NFMS, emulsifiers, coloring, and flavoring. Imitation - no milk products, contain water, corn syrup solids, sugar, vegetable fat, protein (Na caseinate or soy protein). Cultured 1. Yogurt - culture of Lactobacillus bulgaricus and Streptococcus thermophilus is used. 2. Buttermilk - Streptococcus lactis. 3. Acidophilus milks - Lactobacillus acidophilus, balance bacteria in GI tract. Other dairy products: 1. Cheese 2. Butter Milk in Food Preparation Effects of Heating Lactoglobulin and lactalbumin are denatured by heat. Increased with acid or salt. Heat causes the decreased dispersion of calcium phosphate. Film or skim forms-coagulated protein, precipitated salts, and fat globules. Browning - caramelization and Maillard reaction Effects of Acid Cause coagulation of casein. As pH decreases from 6.6 to 4.6, colloidally dispersed casein becomes unstable, adheres and forms curds. Calcium is lost. Effects of Enzymes Rennin clots milk, requires 40-42° C or 104108° F and slightly acid medium. Effects of Phenolic Compounds and Tannins cause increased curdling with heat. Effects of Salts Salts and NaCl in foods may cause coagulation of proteins Creams Half & Half - 10.5 to 18 % cream Light or coffee cream - 18 to 30% cream Light whipping cream - 30 to 36% cream Heavy whipping cream - 36% or more cream Sour cream - Streptococcus lactis Dried cream Nondairy creamer - corn syrup solids, vegetable fat, protein (Na caseinate or soy), emulsifier, salt Nondairy whipped topping - sugar, vegetable oil (hydrogenated), Na caseinate, emulsifiers Whipped Cream Foam is a dispersion of gas in a liquid. Foaming agent lowers surface tension allowing liquid to surround gas. Stabilizing agent keeps gas separated. In cream, liquid is the water in cream, gas is air beaten in, foaming agent is protein where film of protein surrounds air bubbles, and fat acts as the stabilizer. Effects on Whipping Cream Temperature - cold Percent of fat Viscosity Sugar Whipped evaporated milk - less fat thus less stable Whipped NFDM - less fat thus less stability, more protein thus more foam formation or bigger volume Cheese Trends In 2005, Americans consumed 31.4 pounds of cheese per person, 8 times more than they did in 1909 and more than twice as much as they did in 1975 More that half (55-65%) of this comes in commercially manufactured and prepared foods, such as fast food sandwiches and packaged snack foods Pasteurized cows’ milk 310C Starter (1-2%, v/v): Rennet (1:15,000) (CaCl2, 0.02%, w/v) . Coagulum Cut the coagulum ~6mm cubes Raise temperature : 300C to 37-390 over ~ 30 min Cook Cook at 37-390C for ~ 1h Whey drainage Cheddaring of the curd Milling of the curd pH ~ 5.2 NaCl, (~ 2%, w/w) Dry salting Moulding and pressing Ripening Cheddar cheese 0.5- 2 years at 6-80C Cheese Making Separation of protein in milk begins with acid, rennin or both which coagulates casein- forms curds Acid - added or from souring Rennin - proteolytic enzyme Curds are cut, heated, drained of whey, salted, formed, ripened by molds or bacteria under temperature and humidity control. Clear liquid left called whey and contains proteins, lactose, water soluble vitamins and some minerals Nutritive Value Protein Fat Vitamin A Minerals (Calcium and Phosphorus) Cheese is high in Na or salt Types of Cheese Soft, semihard, hard - moisture content Unripened or Ripened - physical and chemical changes in aroma, flavor, texture, and composition. Sharp or mild. Mold or bacteria ripened. Cold pack - mixing varieties of cheese with added acid, salt, water, coloring and spice. Processed cheese - blending cheese with heat and emulsifier. Processed cheese food and spread - similar to processed cheese with less cheese and more milk products plus stabilizers. Cooking Cheese Hard cheese softens, then melts at low temperature. More heat leads to separation of fat and development of tough rubbery curd which forms strings and hardens on cooling. Well ripened cheese and processed cheese blend better in heated mixtures than mild natural cheeses and are less likely to produce a grainy texture and stringiness Milk sugar causes browning in cheese which is exposed to dry heat. Summary Milk is an essential nutrient Milk can be used in the manufacture of various dairy products Each product has its own characteristic in terms of sensory properties Dairy products are used in everyday cooking and industrially prepared foods Power Point Authors Jon Christiano & Dr. Jane Ross The University of Vermont Foods and Nutrition Basic Concepts of Food