งานนำเสนอ PowerPoint

advertisement

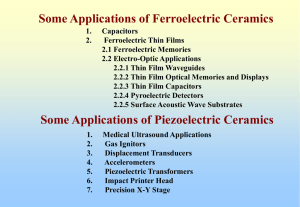

Types of Ferroelectric Materials Ferroelectric Materials can be structurally categorized into 4 groups: 1. Corner Sharing Octahedra: 1.1 Perovskite-Type Compounds (such as BaTiO3, PT, PZT, PMN, and PLZT) 1.2 Lithium Niobate and Tantalate (such as LiNbO3 and LiTaO3) 1.3 Bismuth Oxide Layer Structured Compounds (such as Bi4Ti3O12 and PbBi2Nb2O9) 1.4 Tungsten-Bronze-Type Compounds (such as PbNb2O6) 2. Compounds Containing Hydrogen Bonded Radicals (such as KDP, TGS, and Rochelle Salt) 3. Organic Polymers (such as PVDF and co-polymers) 4. Ceramic Polymer Composites (such as PZT-PE) Done LiNbO3 and LiTaO3 Single Crystals ! Important ferroelectric crystals ! (FE discovered in 1949) Large crystals grown by Czochralski’s technique Excellent piezoelectric, pyroelectric, optical and electro-optics properties Very stable with very high Tc (1210 C for LiNbO3 and 620 C for LiTaO3 ) Chemically stable and insoluble in water and organic solvents Mostly used in crystal form (partly due to limited piezoelectric activity in ceramic form) High mechanical Qm and low acoustic losses Good high frequency transducers and surface acoustic wave devices Good high temperature transducers Infrared detectors (due to LiTaO3’s good pyroelectricity) Laser modulator, frequency multiplier, wave generator (as a result of their good optic and electro-optic properties LiNbO3 and LiTaO3 Single Crystals O Li Nb O Nb Li O Nb Li O “Restricted Perovskite” Structures of LiNbO3 and LiTaO3 are similar (but not identical) to Ilminite (FeTiO3) Connected Distorted Oxygen Octahedra Neighboring octahedra connected through a “common tie-end” oxygen ion (corner-sharing of MO6 (M = Nb or Ta)) Share “one” face with LiO6 Share opposite face with empty O6 octahedral Sequence Nb (or Ta), vacancy, Li, Nb (or Ta), vacancy, Li, ...... LiNbO3 and LiTaO3 Single Crystals Ferroelectric-Paraelectric Phase Transition Second-order or “very close to” second-order phase transition Ps along c-axis (ions displacement direction) and only 180° domains (hard to get substantial piezoelectricity in ceramics) Nb5+ moves to center of the oxygen octahedral Li+ moves towards the nearest oxygen plane Nb5+ at the median between the nearest oxygen planes (Ps = 0) Trigonal (or Hexagonal) structure with 3m ferroelectric phase LiNbO3 and LiTaO3 Single Crystals Orientation Dependence of electromechanical coupling factor k31 of LiNbO3 Piezoelectric Applications Anisotropic Properties : Directional Dependent Properties High coupling (~0.50) and low-temperature dependence of resonant frequency (higher than quartz) ZYw (20°-50°)-cut High Qm Suitable high-frequency filter applications LiNbO3 and LiTaO3 Single Crystals Orientations for LiNbO3 crystal plates for ultrasonic transducers High Frequency Ultrasonic Transducer Applications Four cut-types for different applications (up to several hundred GHz) Z-cut for thickness-extension vibrational mode (low kt ~ 0.17) 35° Y-cut for another thickness-extension vibrational mode 163° Y-cut for strong thickness-sheer mode X-cut for strong thickness-sheer mode with high effective coupling factor of 0.68 Other Piezoelectric Applications Ultrasonic Wave Propagator (due to low acoustic loss) Microwave Acoustic Amplifier LiNbO3 and LiTaO3 Single Crystals Pyroelectric Applications High Curie temperature, substantial pyroelectric coefficient, chemical and physical stability, and lower dielectric constant Materials for Infrared Detectors Electro-optic Applications Most important applications Good linear electro-optical effect Photoelastic effect Non-linear optical effect Large-sized and optical quality crystals Electro-Optical (EO) Modulation Devices • linear EO modulator • • traveling-wave modulator • • wave-guide modulator • • EO Q-switch • Optical Frequency Doubler Bismuth Oxide Layer Structure Ferroelectrics Bi4Ti3O12 and Pb(Bi2Nb2O9) Corner-linked perovskite-like sheets separated by (Bi2O2)2+ layers with perovskite-like unit (1, 2, 3, or more units) General Formula (Bi2O2)2+(Am-1BmO3m+1)2A = Bi, Pb, Ba, Sr, Ca, Na, K B = Ti, Nb, Ta, W, Mo, Fe, Co, Cr Ferroelectric at room temperature Melting point above 1100 C Curie Temperature ~ 300-700 C Bi4Ti3O12 Tc ~ 675 C T < Tc : FE Monoclinic (Pseudo-Orthorhombic) T > Tc : PE Tetragonal Bismuth Oxide Layer Structure Ferroelectrics Bi2PbNb2O9 Bi4Ti3O12 Bi4BaTi4O15 Alternating Layer Structures of Oxygen Octahedra A a layer composed of (Bi2Ti3O10)2B a unit of an imaginary perovskite structure of BiTiO3 C a layer of (Bi2O2)2+ Bismuth Oxide Layer Structure Ferroelectrics Bi4Ti3O12 and Pb(Bi2Nb2O9) Plate-like crystal structure Highly anisotropic FE properties Ceramics do not have very good piezoelectric properties (as a result of low poling efficiency and high coercive field) Improved by grain-orientation during processing (tape-casting and hot-forged sintering Important Piezoelectric Ceramics Higher stability Higher operating temperature (High Tc) Higher operating frequency Piezoelectric Resonator Ferroelectric Optical Memory Devices (Bi4Ti3O12 crystals) Tungsten-Bronze-Type Ferroelectrics Projection of the Tungsten-Bronze Structure on the (001) plane (Orthorhombic and Tetragonal Cells are shown in solid and dotted lines) Tetragonal Tungsten Bronze KxWO3 (x<1) (A1)2(A2)4(C)4(B1)2(B2)8O30 A1, A2, C, B1, B2 are partially or fully occupied Tungsten-Bronze-Type Ferroelectrics Tetragonal Tungsten Bronze (A1)2(A2)4(C)4(B1)2(B2)8O30 A1, A2, C, B1, B2 partially or fully occupied IF one in six of A1 and A2 is vacant AB2O6 5 ions in A1 and A2 5+ 10 Nb ions in B1 and B2 Pb2+ Structure with Open Nature Wide range of cation and anion substitutions without loss of ferroelectricity More than 85 Tungsten-Bronze-Type ferroelectrics PbNb2O6 Lead Niobate First Non-Perovskite Oxide-Type Ferroelectric Discovered Tungsten-Bronze-Type Ferroelectrics Lead Niobate (PbNb2O6) High Tc ~ 560 C, Large d33/d31, Large dh (dh = d33+2d31), and Low mechanical Q Broad-band, high-temperature, transducer applications Processing difficulties • hard to obtain ceramics with < 7% porosity • • a stable non-ferroelectric rhombohedral phase formed • • large volume change from phase trnasformation during cooling leads to cracks • Other Alkali/Alkali-Earth Niobate Materials PbTa2O6, BaNb2O6, SrNb2O6, Pb½Ba½Nb2O6, Sr½Ba½Nb2O6 Potential Applications laser modulation pyroelectric detectors hydrophones ultrasonic applications Some Other Corner-Sharing Octahedra Ferroelectrics CaZrO3, SrZrO3, SrTiO3, CaTiO3, PbHfO3, KNbO3, NaNbO3, AgNbO3, KTaO3, NaTaO3, AgTaO3, RbTaO3, KTa1-xNbxO3 (KTN), BiFeO3, WO3 and their solid-solutions PbTa2O6, SrTa2O7, Cd2Nb2O7, KSr2Nb5O15, Ba2NaNb5O15, Sr4KLiNb10O30 (K,Na)(Sr,Ba)Nb2O6 (KNSBN) and their solid solutions NaVO3, AgVO3, BaAl2O4 !! This is jut a small portion of an endless list of ferroelectric materials!! Types of Ferroelectric Materials Ferroelectric Materials can be structurally categorized into 4 groups: 1. Corner Sharing Octahedra: 1.1 Perovskite-Type Compounds (such as BaTiO3, PT, PZT, PMN, and PLZT) 1.2 Lithium Niobate and Tantalate (such as LiNbO3 and LiTaO3) 1.3 Bismuth Oxide Layer Structured Compounds (such as Bi4Ti3O12 and PbBi2Nb2O9) 1.4 Tungsten-Bronze-Type Compounds (such as PbNb2O6) 2. Compounds Containing Hydrogen Bonded Radicals (such as Rochelle Salt, KDP, and TGS) 3. Organic Polymers (such as PVDF and co-polymers) 4. Ceramic Polymer Composites (such as PZT-PE) Done Ferroelectrics with Hydrogen Bonded Radicals KDP, TGS, and Rochelle Salt Still being used in some applications Superior in some features and properties Large crystals with optical quality easily grown from aqueous solution Rochelle salt has very good piezoelectric properties KDP family has good electro-optic and non-linear optic properties TGS family has very excellent pyroelectric properties Disadvantages Reasonably weak ferroelectricity, low Tc, poor mechanical properties. and water soluble Gradually being replaced by piezoelectric ceramics and crystals Ferroelectrics with Hydrogen Bonded Radicals Rochelle Salt NaKC4H4O6 • 4H2O Sodium Potassium Tantalate Tetrahydrate First Ferroelectric Material Discovered 2 Transition Temperatures (-18 C and +24 C) -18 C Monoclinic Ferroelectric with point group 2 +24 C T > 24 C Paraelectric Orthorhombic with point group 222 Second-Order FE-to-PE Phase Transition PE Phase with Piezoelectric Properties Rochelle Salt Excellent Piezoelectric Transducers Sonar, Hydrophone, Microphone Ferroelectrics with Hydrogen Bonded Radicals Rochelle Salt Projection of the structure on (001) plan showing the hydrogen-bond system Ferroelectrics with Hydrogen Bonded Radicals Rochelle Salt Temperature dependence of the dielectric constant showing the dielectric anomalies corresponding to two transition temperatures Ferroelectrics with Hydrogen Bonded Radicals KDP KH2PO4 Potassium Dihydrogen Phosphate Non-Ferroelectric Phase at Room Temperature (Tetragonal 42m) Non-Ferroelectric with Piezoelectric at Room Temperature Curie Temperature at ~ –150 C FE Orthorhombic Phase with point group mm2 First-Order FE-to-PE Phase Transition KDP Good Electro-Optic and Non-Linear Optic Properties Electro-optic devices, High-power pulse laser Electro-optic modulator, and Light-valve devices Ferroelectrics with Hydrogen Bonded Radicals KDP Structural Framework of KDP (Hydrogen positions are shown only schematically) Ps along c-axis as a result of K+ and P5+ ions displacement in c-directions (Ps aligned in 180°) Ferroelectrics with Hydrogen Bonded Radicals TGS (NH2CH2COOH)3H2SO4 Triglycine Sulfate FE Phase at Room Temperature (Monoclinic point group 2) Curie Temperature at ~ 49.7 C PE Monoclinic Phase with point group 2/m (Paraelectric with E-induced Piezoelectricity) Second-Order FE-to-PE Phase Transition (order-disorder type) TGS Good Pyroelectric Properties for Infrared Detectors Largest response sensitivity among known pyroelectric crystals Disadvantages include easily depolarized (even at room temperature) (as a result of low Tc) Ferroelectrics with Hydrogen Bonded Radicals TGS Structure of TGS: I, II, and III represent different glycine groups Hydrogen-bonds between Groups II and III Ordering of N in Group I results in Ps in b-direction Types of Ferroelectric Materials Ferroelectric Materials can be structurally categorized into 4 groups: 1. Corner Sharing Octahedra: 1.1 Perovskite-Type Compounds (such as BaTiO3, PT, PZT, PMN, and PLZT) 1.2 Lithium Niobate and Tantalate (such as LiNbO3 and LiTaO3) 1.3 Bismuth Oxide Layer Structured Compounds (such as Bi4Ti3O12 and PbBi2Nb2O9) 1.4 Tungsten-Bronze-Type Compounds (such as PbNb2O6) 2. Compounds Containing Hydrogen Bonded Radicals (such as Rochelle Salt, KDP, and TGS) 3. Organic Polymers (such as PVDF and co-polymers) 4. Ceramic Polymer Composites (such as PZT-PE) Done Organic Polymer Ferroelectrics During 1940s Piezoelectricity in biological materials, e.g. wood In the Mid 1970s Ferroelectricity and Pyroelectricity in synthetic materials PVDF or PVF2 (P(VDF-TrFE), e- irradiated P(VDF-TrFE), Polyurethane, Silicone, and Acrylic) Applications utilized Electromechanical Properties Underwater ultrasonic transducers Electro-acoustic transducers (microphones, earphones, loudspeakers) Other applications button-switches coin-sensors Organic Polymer Ferroelectrics PVDF PVF2 (CH2-CF2)n Polyvinylidene Fluoride P(VDF-TrFE) Co-Polymers TrFE Tri-Fluoroethylene e-irradiated P(VDF-TrFE) Co-Polymers Ferroelectric Materials Piezoelectric/Pyroelectric/Electrostrcictive Applications Better for uses in transducers and medical imaging applications • Advantages • low-density provides little acoustical mismatch with water and human tissues flexible and conformable to any shape • Problems • large dielectric loss at high-frequency low Tc and degradation t low-temperature (70-100 C) low poling efficiency in samples thicker than 1 mm Organic Polymer Ferroelectrics PVDF and P(VDF-TrFE) Co-Polymers PVDF is a polar material by nature (due to H+ and F- positions with respect to C-atoms) Polarization can be induced by stretching, high-temperature annealing, or application of high electric field Organic Polymer Ferroelectrics PVDF and P(VDF-TrFE) Co-Polymers P-E loop with different crystal forms d31 at different poling field Ep Polarization is induced from orienting crystalline phase of polymer under application of high electric field Piezo/Pyro Properties depend on degree of crystallinity and FE polarization in the crystalline phase, and also on the poling conditions (both electric field and temperature) Organic Polymer Ferroelectrics e-irradiated P(VDF-TrFE) Co-Polymers Dielectric constant and loss as a function of temperature for P(VDF-TrFE) 50/50 copolymer after 100 Mrad e-irradiation dose P-E Loops for P(VDF-TrFE) 50/50 copolymer at room temperature before and after e-irradiation dose Organic Polymer Ferroelectrics e-irradiated P(VDF-TrFE) Co-Polymers P-E Loops for P(VDF-TrFE) 50/50 copolymer at different temperatures after 100 Mrad e-irradiation dose Variation of remanent polarization with temperature for P(VDF-TrFE) 50/50 copolymer before and after eirradiation dose Organic Polymer Ferroelectrics e-irradiated P(VDF-TrFE) Co-Polymers Electric field induced strain versus electric field for P(VDFTrFE) 50/50 copolymer at room temperature after 100 Mrad e-irradiation dose Influence of irradiation on induced strain for P(VDFTrFE) 50/50 copolymer at room temperature Types of Ferroelectric Materials Ferroelectric Materials can be structurally categorized into 4 groups: 1. Corner Sharing Octahedra: 1.1 Perovskite-Type Compounds (such as BaTiO3, PT, PZT, PMN, and PLZT) 1.2 Lithium Niobate and Tantalate (such as LiNbO3 and LiTaO3) 1.3 Bismuth Oxide Layer Structured Compounds (such as Bi4Ti3O12 and PbBi2Nb2O9) 1.4 Tungsten-Bronze-Type Compounds (such as PbNb2O6) 2. Compounds Containing Hydrogen Bonded Radicals (such as Rochelle Salt, KDP, and TGS) 3. Organic Polymers (such as PVDF and co-polymers) 4. Ceramic Polymer Composites (such as PZT-PE) Done Ceramic-Polymer Composites Why composites? Drive for desired properties NOT obtainable in single phase (ceramics or polymers) For instance, Electromechanical Transducers Requirements Maximum piezoelectric sensitivity, minimum density for better matching flexible for conformity to any curved surface !! Single Phase Ceramics or Polymers DO NOT match all these requirements !! PZT: high d33, low dh, low voltage coefficient g PVDF: highly sensitivity, low strain coefficient Composites Optimize the most useful properties of the two phases which do not ordinarily appear together Ceramic-Polymer Composites Made up of an active ceramic phase embedded in a passive polymer phase Properties depend on Connectivity, volume percentage of ceramic phase, and spatial distribution of the active phase in the composite Connectivity (developed by Newnham, Skinner, and Cross) Arrangement of component phases within a composite A-B A: number of direction in which the active phase is self connected B: number of direction in which the passive phase is self connected Diphasic Composies : 10 types : 0-0, 1-0, 2-0, 3-0, 1-1, 2-1, 3-1, 2-2, 3-2, 3-3 Ceramic-Polymer Composites 10 Connectivity Patterns for Diphasic Composites Ceramic-Polymer Composites Connectivity of Constituent Phases in Piezoelectric Ceramic-Polymer Composites Ceramic-Polymer Composites The piezoelectric coefficient of the composite for the series connection can be expressed as follows V 1d 33 2 33 2V 2d 33 1 33 1 2 V 33 2V 1 33 The piezoelectric coefficient of the composite for the parallel connection can be expressed as follows V 1d 33 2 s33 2V 2d 33 1 s33 1 2 V s33 2V 1s33 1 1 c d 33 And using g33 = d33/33 : c g 33 V 1g 33 2V 2g 33 Note that: a very thin low r will lower d, but no effect on g c d 33 If 1d33 >> 2d33 and 1s33 << 2s33 , then for small 1V: cd 33 ~ 1d33 and very high cg33 !! Enhanced Properties!! Ceramic-Polymer Composites Volume Fraction Dependence of r, d33, g33 in 3-1 PZT:Polymer Composite Ceramic-Polymer Composites Main Applications for Transducers Transducers for Sonar Hydrophone : an element(s) in a sonar system used to detect ultrasound gh = hydrostatic voltage coefficient = voltage induced from applied stress dh = hydrostatic charge coefficient = charge induced from applied stress Figure of Merit (FOM) = gh•dh Medical Transducers Non-ionizing, low-risk o reproductive organs and foetus Major organs and malfunction Ideal Transducer Materials Requirements High electro-mechanical coupling coeffcient High FOM, Low Q, Acoustic Impedance Matching with medium Piezoelectric Ceramic-Polymer Composites Ceramic-Polymer Composites Comparison of Hydrophone Figure of Merit of Several Piezoelectric Ceramics and Transducer Designs Ceramic-Polymer Composites Piezoelectric Composites to Use as Sensors, Actuators, and Transducers Types of Ferroelectric Materials Ferroelectric Materials can be structurally categorized into 4 groups: 1. Corner Sharing Octahedra: 1.1 Perovskite-Type Compounds (such as BaTiO3, PT, PZT, PMN, and PLZT) 1.2 Lithium Niobate and Tantalate (such as LiNbO3 and LiTaO3) 1.3 Bismuth Oxide Layer Structured Compounds (such as Bi4Ti3O12 and PbBi2Nb2O9) 1.4 Tungsten-Bronze-Type Compounds (such as PbNb2O6) 2. Compounds Containing Hydrogen Bonded Radicals (such as Rochelle Salt, KDP, and TGS) 3. Organic Polymers (such as PVDF and co-polymers) 4. Ceramic Polymer Composites (such as PZT-PE) Done