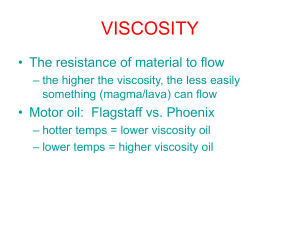

Pulp Viscosity

advertisement

Agenda • Carbohydrate Reaction Mechanisms » Glycosidic Cleavage » Peeling » Stopping • • • • • Glucomannan Reactions Xylan Reactions Other Hemicellulose Reactions Cellulose Reactions Viscosity 1 Carbohydrate Reactions • The main alkaline reactions of carbohydrates : » Glycosidic cleavage. » Peeling. » Stopping. 2 Peeling Mechanism * The peeling reaction basically unzips the carbohydrates by removing terminal sugars one at a time. Reaction takes place from reducing end of the molecule (aldehyde). Reducing end group Stable end group 3 Peeling Mechanism CHO HCOH HOCH CH2OH C O HOCH CH2OH - C O + -H HOC HCOR HCOR HC OR HCOH HCOH HCOH CH2OH CH2OH - - RO CH2OH CH2OH CH2OH C O C O HOC C O CH CH2 HCOH HCOH CH2OH Acids formed by peeling reaction responsible for most alkali consumption in kraft cook + H2O C(OH)CH2OH CH2 HCOH CH2OH CH2OH glucoisosaccharinic acid * The peeling reaction basically unzips the carbohydrates by removing terminal sugars one at a time. Reaction takes place from reducing end of the molecule (aldehyde). CO2H CH2OH CHO COOH C O C O CHOH CH2OH CH3 CH3 Lactic Acid CHO CHO HCOH COH CH2OH CH2 4 Stopping Mechanism CHO HCOH HOCH (A) HC O (-) COH HO CH (B) - -HO CHO (C) CHO COH C O CH CH2 CO2H HCOH + H2O CH2 HCOR HCOR HCOR HCOR HCOR HCOH HCOH HCOH HCOH HCOH CH2OH CH2OH CH2OH * The stopping reaction stops the peeling process when an endgroup is formed which will mot peel. CH2OH CH2OH glucometasaccharinic acid (will not “peel”) 5 Hydrolysis of Glycosidic Linkage • Cleavage of glycosidic bonds. » This reaction cleaves the carbohydrate in the chain instead of at the end of the chain as in the peeling reaction. This generates a new reducing end which increases the rate of peeling. • This reaction lowers the molecular weight of carbohydrates. » Glycosidic cleavage of cellulose results in loss of pulp viscosity and can lead to strength loss if too extensive (-) CH2OH CH2OH O HO HO OMe + -H CH2 CH2 O - OH - MeO O OH OH O O O OMe HO OH O (-) OH O OH OH 6 100 200 80 150 60 Glucomannan Temperature 40 100 50 20 0 Temperature (C) Glucomannan Yield (%) Loss of Glucomannans During Kraft Pulping 0 0 50 100 150 200 250 Time (minutes) 7 120 200 100 150 80 25% EA 60 100 15.8% EA 40 50 20 0 Temperature (C) Glucomannan Yield (%) Effect of Effective Alkali on Glucomannan Loss 0 0 50 100 150 200 250 300 Time (minutes) 8 Glucomannan losses • Glucomannans are lost mainly through primary peeling. » Responsible for much of yield loss, especially in softwoods » Pulp yield can be increased by stabilizing glucomannans - Oxidize reducing end group with either polysulfide or anthraquinone 9 100 200 80 150 60 100 40 Xylan Temperature 20 50 0 0 50 100 150 200 Temperature (C) Xylan Yield (%) Loss of Xylans During Kraft Pulping 0 250 Time (minutes) 10 Effect of Effective Alkali on Xylan Loss 200 100 150 80 60 100 40 25% EA 15.8% EA 20 50 0 0 50 100 150 200 250 Temperature (C) Xylan Yield (%) 120 0 300 Time (minutes) 11 Xylan losses • Xylans are lost mainly through glycosidic cleavage (and some secondary peeling). » Dissolve as macromolecule which can re-precipitate back on to the pulp fibers if [OH-] becomes low enough – end of the cook - End group stabilization not very effective for hardwoods » Responsible for substantial yield loss in hardwoods » Presence of xylans on pulp have a significant effect on its performance - Refining is easier with xylans in the pulp - Xylans appear to inhibit bleaching 12 Cellulose Reactions During Kraft Pulping • Cellulose undergoes peeling and glycosidic cleavage reactions during kraft pulping. » Because cellulose molecules are so long, peeling reactions only cause small yield losses. » Glycosidic cleavage is more of a problem because of molecular weight losses that may cause strength problems. This reaction also increases the rate of peeling somewhat through generation of new reducing end groups. • Because cellulose molecules are so large dissolution is not an issue. 13 Pulp Viscosity • Modifying the hemicellulose content of the pulp won’t change the viscosity » Borohydride treatment inhibits primary peeling which increase glucomannan content 14 Pulp Viscosity • Pulp strength and viscosity has a complex relation » A decrease in viscosity may not correlate with pulp strength until the viscosity reaches a critical level – then look out! 15 Pulp Viscosity • Pulp strength and viscosity has a complex relation » A decrease in viscosity may not correlate with pulp strength until the viscosity reaches a critical level – then look out! 16 Pulp Viscosity Zero span tensile(kPa) 180 160 140 120 100 80 60 0 5 10 15 20 25 30 35 40 45 CED Viscosity (mPa.s) Borohydride treated Untreated 17 Pulp Viscosity • Pulp strength and viscosity has a complex relation » A decrease in viscosity may not correlate with pulp strength until the viscosity reaches a critical level – then look out! 18 Pulp Viscosity • Pulp strength and viscosity has a complex relation » The retention of hemicelluloses can, however, reduce the strength of the pulp without any affect on the pulp’s viscosity 19