Dr N Dharmadhikari -QbD in Product Development

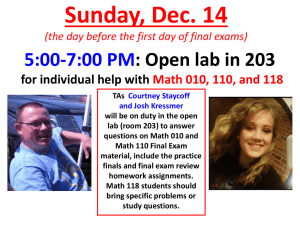

advertisement

Regulatory Compliance for Global Pharma Market Quality by Design (QbD) in Product Development Dr. Nitin Dharmadhikari Sun Pharma Advanced Research Company Ltd., Mumbai 18th Dec ’12 This document is the property of SPARCL 1 What is QbD? Systematic, holistic and proactive approach to pharmaceutical development. Begins with predefined objectives Emphasizes product and process understanding and process control Based on sound science and quality risk management Ref.: ICH Q8 (R2) 18th Dec ’12 This document is the property of SPARCL 2 Why QbD? Generic industry business model: Regulator’s perspective File first, learn later Major amendments during review process - Exhibit batch stability failure, formulation revision Longer time for generic product approval Approved product may not be marketed Post approval changes – prior approval supplements 18th Dec ’12 This document is the property of SPARCL 3 How QbD will help improve? Ensure higher level of assurance of product quality for patient Improved product and process design & understanding Monitoring, tracking & trending of product & process. More efficient regulatory oversight Efficiency and cost saving for industry Increase efficiency of manufacturing process Minimize / eliminate potential compliance actions 18th Dec ’12 This document is the property of SPARCL 4 Overview of QbD Quality Target Product Profile Product Design and Understanding Process Design and Understanding Control Strategy Continuous Improvement 18th Dec ’12 This document is the property of SPARCL 5 Elements of QbD Quality Target Product Profile (QTPP) Define Critical Quality Attributes (CQAs) Perform risk assessment Link raw material attributes and process parameters to CQAs Design and implement a control strategy Manage product lifecycle, including continuous improvement 18th Dec ’12 This document is the property of SPARCL 6 Quality Target Product ProfileQTPP What is QTPP? A set of elements that defines the drug product The target or goal set in advance A guide to Drug Product development What forms the basis for QTPP? The RLD and its label Applicable regulatory guidelines When to define QTPP? At the start of development Knowledge gained in development may change some elements 18th Dec ’12 This document is the property of SPARCL 7 Components of QTPP Components related to safety, efficacy, identity, purity and potency Critical and non-critical components, e.g. Critical: Assay, content uniformity Non-critical: Appearance Fixed and variable components Fixed elements must be present e.g. Dosage form, strength Variable elements may have a range of acceptable values e.g. Tablet weight, assay 18th Dec ’12 This document is the property of SPARCL 8 QTPP components for IR tablet Example Dosage Form Route of administration Strength Weight Pharmacokinetics Appearance Identity Assay Impurities Content uniformity Friability Dissolution Residual solvents 18th Dec ’12 This document is the property of SPARCL 9 Specific requirements in QTPP Scored tablets Weight variation between two halves Dissolution of half tablet Orally Disintegrating tablets Hardness Disintegration time Container closure Extended Release products Alcohol induced dose dumping 18th Dec ’12 This document is the property of SPARCL 10 Critical Quality Attributes – CQAs CQAs are a subset of the QTPP Include critical parameters that are likely to change based upon variations in raw materials and processes -Identity test for dosage form – Not a CQA -Assay, Content uniformity – CQAs CQAs are monitored throughout the DP development. CQAs ensure that DP remains within safe and effective levels. 18th Dec ’12 This document is the property of SPARCL 11 QTPP and CQAs QTPP components Dosage Form Route of administration Strength Weight CQAs Pharmacokinetics Assay (efficacy) Appearance Identity Assay Impurities (safety) C.U. (efficacy) Dissolution (efficacy) Impurities Content uniformity Friability Dissolution Residual solvents 18th Dec ’12 This document is the property of SPARCL 12 QTPP and Specifications QTPP Specifications Desired target for developmental work Includes all of the CQAs Components of QTPP may or may not Specification is a list of be in specification - Not in spec – Dosage form, strength - In spec – Assay, impurities Does not include acceptance criteria - tests, references to analytical procedures acceptance criteria Establishes the set of criteria to which DP should conform to be considered acceptable for its intended use Defining a QTPP does not mean setting all acceptance criteria or the product specifications before development work begins. 18th Dec ’12 This document is the property of SPARCL 13 QbD Tools – Risk Assessment Why risk assessment in product development? To identify relative risk levels at the beginning of product development To prioritize limited development resources To document the decision making process throughout development To assess the needs of additional studies for scale up and technology transfer To identify appropriate specifications, critical process parameters and manufacturing controls To decrease variability of critical quality attributes 18th Dec ’12 This document is the property of SPARCL 14 Risk Assessment Risk assessment for Formulation – starting material properties, levels of components Manufacturing process Steps for risk assessment List out all components / processes Prepare the process flow chart Identify all potential failure modes for each item with risk query (what might go wrong?) Risk analysis Risk evaluation 18th Dec ’12 This document is the property of SPARCL 15 Risk Assessment Various formal methodologies available for risk assessment Failure Mode Effects Analysis & Failure Mode Effects & Criticality Analysis Hazard & Operability Analysis Supporting statistical tools It is neither always appropriate nor always necessary to use a formal risk management process….. The use of informal risk assessment processes can also be considered acceptable. – ICH Q9 A risk-based justification based on experience and data is always necessary! 18th Dec ’12 This document is the property of SPARCL 16 Risk Assessment Quality by Design for ANDAs: An Example for Immediate-Release Dosage Forms Generic product development for Acetriptan Tablets, 20 mg. Acetriptan is a BCS Class II compound displaying poor aqueous solubility (less than 0.015 mg/mL) across the physiological pH range. It exists in three different polymorphic forms which may affect dissolution. Polymorph III is the most stable polymorph. Drug product is prepared with roller compaction process. 18th Dec ’12 This document is the property of SPARCL 17 Risk assessment Risk assessment for formulation components Formulation Variables Drug Product CQA Drug Substance PSD MCC/Lactose Ratio CCS Level Talc Level Magnesium Stearate Level Assay MEDIUM MEDIUM LOW LOW LOW Content Uniformity HIGH HIGH LOW LOW LOW Dissolution HIGH MEDIUM HIGH LOW HIGH Degradation Products LOW LOW LOW LOW MEDIUM 18th Dec ’12 This document is the property of SPARCL 18 Risk assessment Risk assessment of DP manufacturing process Process Steps Drug Product CQAs Pre-RC* Blending and Lubrication Roller Compaction Milling Final Blending and Lubrication Compression Assay MEDIUM LOW MEDIUM LOW MEDIUM Content Uniformity HIGH HIGH HIGH LOW HIGH Dissolution MEDIUM HIGH MEDIUM HIGH HIGH Degradation Products LOW LOW LOW LOW LOW * RC: Roller compaction 18th Dec ’12 This document is the property of SPARCL 19 Justification for assigned risks Process Steps Drug Product CQAs Assigned Risk Assay MEDIUM Justification Suboptimal pre-roller compaction blending and lubrication may cause variable flowability of the blend affecting Assay. The PSD and cohesiveness of the drug substance Pre-Roller Compaction Content Uniformity HIGH adversely impact its flowability. If not blended properly with excipients, it may affect CU. Blending Blending process variables may impact the distribution of and Lubrication Dissolution MEDIUM CCS in the blend which could impact disintegration of the granules and ultimately, dissolution of the tablets. Degradation Products 18th Dec ’12 LOW Blending process variables are unrelated to the degradation products of Generic Acetriptan Tablets, 20 mg. This document is the property of SPARCL 20 CMAs, CPPs and CQAs What factors affect drug product CQAs? Properties of Input Materials- Identify Critical Material Attributes (CMAs) Properties of in-process materials- CQAs of one step become CMAs for a downstream unit operation Manufacturing process parameters- Identify Critical Process Parameters (CPPs) CPPs2 CPPs1 CMAs1 Input Materials 18th Dec ’12 Unit Operation 1 CMAs2 Output Materials CQAs Unit Operation 2 This document is the property of SPARCL Product 21 Critical Material Attributes (CMAs) Risk Assessment of the drug substance attributes Drug Substance Attributes Drug Product CQAs Solid State Form Hygroscopicity Particle Size Residual Solvents Process Impurities Chemical Stability Physical Attributes (size and splitability) LOW LOW LOW LOW LOW LOW Assay LOW LOW LOW LOW LOW LOW Content Uniformity LOW LOW LOW LOW LOW LOW Drug Release HIGH LOW HIGH LOW LOW LOW Solid state form and particle size of DS are CMAs 18th Dec ’12 This document is the property of SPARCL 22 CPPs Risk assessment of manufacturing process Identify high risk steps (unit operation) that affect the CQAs of DP. Process Steps Drug Product CQAs Pre-RC* Blending and Lubrication Roller Compaction Milling Final Blending and Lubrication Compression Assay MEDIUM LOW MEDIUM LOW MEDIUM Content Uniformity HIGH HIGH HIGH LOW HIGH Dissolution MEDIUM HIGH MEDIUM HIGH HIGH Degradation Products LOW LOW LOW LOW LOW 18th Dec ’12 This document is the property of SPARCL 23 CPPs Process Step: Compression CPPs Main compression force DP CQAs Risk Assessment Content Uniformity LOW Dissolution HIGH Justification and Strategy CU is dominated by BU and flowability and is unrelated to main compression force. Suboptimal compression force may affect tablet hardness and friability and, ultimately, dissolution. Press speed (dwell time) Content Uniformity A faster than optimal press speed may cause HIGH inconsistent die filling and weight variability which may then impact CU and dissolution. For efficiency, the press speed will be set as fast as practically Dissolution 18th Dec ’12 HIGH possible without adversely impacting tablet quality. This document is the property of SPARCL 24 Control Strategy “A planned set of controls, derived from current product and process understanding that ensures process performance and product quality…..” ICH Q8 (R2) & Q10 Control Strategy includes following elements (but not limited to): Input material attributes (e.g. drug substance, excipients, container closure) Equipment operating conditions (process parameters) In-process controls Finished product specifications Controls for each unit operations Methods and frequency of monitoring and control. 18th Dec ’12 This document is the property of SPARCL 25 Control Strategy 18th Dec ’12 This document is the property of SPARCL 26 Control Strategy Control Strategy Implementation Options Enhanced Approach Level 1 Real-time automatic control + Flexible process parameters Level 2 Reduced end product testing + Flexibility for critical material attributes and critical process parameters within design space Traditional Approach 18th Dec ’12 Level 3 End product testing + tightly constrained material attributes and process parameters This document is the property of SPARCL 27 QbD Tools – DoE Design of experiments (DoE) Useful for screening of variables with significant impact on DP CQAs Classical approach uses OFAT (One Factor At A Time) Limited number of experiments gives limited information. DoE helps study effects of interaction of multiple factors at a time Used in optimization studies, enables creation of “design space” “Design space” is proposed by the applicant and subject to regulatory assessment and approval. “Design space” developed at lab or pilot scale can be proposed for commercial scale, but needs to be verified at production scale for scale dependant parameters. 18th Dec ’12 This document is the property of SPARCL 28 Process Analytical Technology (PAT) Timely measurements during processing Critical quality and performance attributes Raw and in-process materials At-line, on-line or in-line measurements Founded on “Process Understanding” Opportunities for improvement More reliable and consistent processes (& product) Less failures, less reworks, less recalls Flexibility w.r.t. scale and equipment Better / faster Quality Systems Process Enhancement Opportunities 18th Dec ’12 This document is the property of SPARCL 29 PAT in Tablet manufacturing Stage Technique Measurement Dispensing NIR / Raman Identification of raw materials Wet Granulation NIR Moisture distribution Drying NIR Moisture content Blending NIR Blend Uniformity Strain gauges Compression force NIR Content Uniformity Compression 18th Dec ’12 This document is the property of SPARCL 30 PAT Examples Spectral Probe NIR Analyzer installed on viewing window of Glatt FBD without any dryer modification. 18th Dec ’12 This document is the property of SPARCL 31 PAT Examples Real-time Blend Uniformity by using TruProcess™ Analyzer 18th Dec ’12 This document is the property of SPARCL 32 QbD: Required or Optional? Required Quality target product profile (QTPP) including critical quality attributes (CQAs) of the drug product and including Product design and understanding Product design and understanding Critical material attributes (CMAs) of the drug substance and excipients Process design and understanding Critical process parameters (CPPs) Control strategy, including justification Optional Design Space Process Analytical Technology 18th Dec ’12 This document is the property of SPARCL 33 QbD 18th Dec ’12 This document is the property of SPARCL 34 QbD 18th Dec ’12 This document is the property of SPARCL 35 References for QbD 1. Guidance for Industry: Q8(R2) Pharmaceutical Development 2. Guidance for Industry: Q9 Quality Risk Management 3. Guidance for Industry: Q10 Pharmaceutical Quality System 4. Guidance for Industry PAT: A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance 5. Quality by Design for ANDAs: An Example for Modified Release Dosage Forms 6. Quality by Design for ANDAs: An Example for Immediate Release Dosage Forms 7. GPhA presentations 8. Draft QbR updated 18th Dec ’12 This document is the property of SPARCL 36