Wet Bulk Micromachining

advertisement

Wet Bulk

Micromachining –

a STIMESI II tutorial

23.02.2011

Per Ohlckers, Vestfold University College

www.hive.no

Per.Ohlckers@hive.no

Daniel Lapadatu, SensoNor Technologies

www.multimems.com

daniel.lapadatu@sensonor.no

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 2

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 3

Manufacturing Processes

Serial (e.g. Focused Ion Milling - FIB) vs. batch (e.g. bulk Si

micromachining) vs. continuous (e.g. doctor’s blade).

Additive (e.g. evaporation) or subtractive (e.g. dry etching).

Projection (almost all lithography techniques) vs. truly 3D.

Mold vs. final product.

There are many different techniques

that are being used.

However, in general, batch processing

is the most powerful technique and

used mostly.

FIB

Slide 4

Micromachining

Bulk Micromachining is a process that produces structures

inside the substrate by selective etching.

Surface Micromachining is a process that creates structures

on top of the substrate by film deposition and selective etching.

Bulk Micromachining

Surface Micromachining

Slide 5

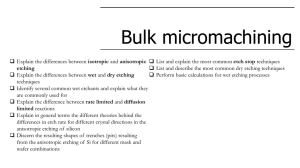

Classification of Bulk Silicon Etching

Bulk Micromachining is a process that produces structures

inside the substrate by selective etching.

Wet Etching

Dry Etching

Crystal orientation

dependent

Process

dependent

Isotropic

Anisotropic

Isotropic

Anisotropic

Acidic

Etchants

Alkaline

Etchants

BrF3

XeF2

F-based

plasmas

Slide 6

Etching Features

Etch rate:

► Rate of removal of material/film.

► Varies with concentration, agitation and temperature of etchant,

porosity and density of etched film.

Etch selectivity:

U

► Relative etch rate of mask,

film and substrate.

Etch geometry:

► Etching depth (R);

R

S

B

► Mask undercut (U);

► Slope of lateral walls (S);

► Bow of floor (B);

► Anisotropy.

Slide 7

Bulk Silicon Etching: Examples

Deep cavity by wet,

anisotropic etching

Release etch

by RIE

Recess etch

by RIE

Slide 8

Wet Silicon Etching: Examples

Isotropic etching with HNA

(HF : Nitric Acid : Acetic Acid)

Anisotropic etching with KOH

(110)

(100)

Slide 9

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 10

Structure of Single Crystal Silicon

Face-centred cubic (fcc) structure

(diamond structure) with two atoms

associated with each lattice point of

the unit cell.

One atom is located in position with

xyz coordinates (0, 0, 0), the other

in position (a/4, a/4, a/4), a being

the basic unit cell length.

Lattice constant a = 5.43 Å.

The arrangement of the silicon atoms in a unit

cell, with the numbers indicating the height of

the atom above the base of the cube as a

fraction of the cell dimension.

Slide 11

Miller Indices

Miller indices are a notation system in crystallography for

planes and directions in crystal lattices.

A lattice plane is determined by three integers h, k and l, the

Miller indices, written (hkl). The indices are reduced to the

smallest possible integers with the same ratio.

Determining the Miller indices for

planes by using the intercepts

with the axes of the basic cell.

Slide 12

Determining Miller Indices

Example:

► Take the intercepts of the plane

along the crystallographic axes, e.g.

2, 1 and 3.

z

4

► The reciprocal of the three integers

are taken:

1/2, 1/1 and 1/3.

3

► Multiply by the smallest common

denominator (in this case 6):

3, 6 and 2.

2

► The Miller indices of the plane are:

(362).

y

1

1

x

O

1

Slide 13

2

3

Crystallographic Planes and Directions

(abc) denotes a plane.

{abc} denotes a family of

equivalent planes.

[abc] denotes the direction

perpendicular on (abc) plane.

<abc> denotes a family of

equivalent directions.

{100}, {110} and {111}

are the most important

families of crystal planes for

the silicon crystal.

Slide 14

Single Crystal Silicon Wafers

Primary and secondary flats

indicate the dopant type and

surface orientation.

Wafer diameter in current fab

standards: from 100 to 300 mm.

Wafer thickness in current fab

standards: from 250 to 600 µm.

Surface orientation:

► (100) for MOS and MEMS;

► (110) for MEMS;

► (111) for bipolar.

Secondary flat

Primary flat

Slide 15

Standard 100 mm Wafers

The position of the flat(s) indicates the surface orientation and

the type of doping.

The primary flat on (100) and (110) wafers is along

the [110] direction.

Orientation of flats for 100 mm wafers

p-(111)

Primary flat

n-(111)

p-(100)

n-(100)

Secondary flat

Slide 16

Wafers Used in MultiMEMS

P-type, 150 mm Si wafer.

(100) ± 0.5º Surface.

[110] ± 0.5º Primary Flat.

z

{100}

Si Wafer

O

x

(100) Surface

<110> Directions

[110]

y

Wafer's Primary Flat

Slide 17

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 18

Isotropic Wet Etching of Silicon

All crystallographic directions are

etched at the same rate.

Features:

► Etchants are usually acids;

Mask

with stirring

Si

► Etch temperature: 20... 50 °C;

► Reaction is diffusion-limited;

► Very high etch rate (e.g. up to

50 µm/min);

Si

without stirring

► Significant mask undercutting.

Masking is very difficult:

► Au/Cr or LPCVD Si3N4 is good.

► SiO2 may also be used for shallow

etching.

Si

Slide 19

Isotropic Etching of Silicon: Etchants

Etchant

(Diluent)

Typical

Composition

Temp.

Etch Rate

[µm/min]

HF

HNO3

CH3COOH + H2O

10 ml

30 ml

80 ml

22 °C

0.7... 3.0

HF

HNO3

CH3COOH + H2O

25 ml

50 ml

25 ml

22 °C

40

HF

HNO3

CH3COOH + H2O

9 ml

75 ml

30 ml

22 °C

7.0

Mechanism

–

hole injection:

oxidation:

oxide removal:

HNO3 + H2O + HNO2 → 2HNO2 + 2OH +

+

2h

4+

–

Si + 4OH → SiO2 + H2

SiO2 + 6HF → H2 SiF6

Slide 20

Silicon Etching with HNA

HNA: mixture of

► 49,23% HF,

► 69,51% HNO3 and

► acetic acid (CH3COOH) or

water (H2O) as diluent.

(µm/h)

HNO3 oxidizes the silicon,

HF removes the oxide:

► High HNO3:HF ratio,

- Etch limited by oxide removal.

► Low HNO3:HF ratio

- Etch limited by oxide formation.

Dilute with water or acetic acid:

► CH3COOH is preferred because it

prevents HNO3 dissociation.

Iso-Etch Curve

(from Robbins et al.)

Slide 21

Isotropic Etching of Glass

Single- or double-side etching of glass wafers is achieved either

by using HF-water solution or HNA.

Typical etch rate for borosilicate glass in HNA: 1.9 µm/min.

Applications:

► Etching cavities and through-holes;

► Etching gas/fluid channels.

Through-hole

Mask

Cavity

Undercut

GLASS

Slide 22

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 23

Anisotropic Wet Etching of Silicon

Crystallographic directions are

etched at different rates.

<110>

Features:

► Etchants are usually alkaline;

<100>

► Etch temperature: 85... 115 °C;

54.74°

► Reaction is rate-limited;

► Low etch rate (ca. 1 µm/min);

Mask

<111>

Si

► Small mask undercutting.

Masking is very difficult:

► LPCVD Si3N4 is good;

► SiO2 may also be used with some

etchants.

Si

Slide 24

Etching Setup

Laboratory setup for wet

chemical etching of silicon.

The principles for industrial

manufacturing equipment

are the same.

Slide 25

Anisotropic Etching of Silicon: Etchants

Etchant

(Diluent)

Typical

Etch Rate Etch Ratio Masking

Temp.

Composition

[µm/min] (100)/(111)

Film

Etylenediamine

Pyrocathecol

Water

750 ml

120 gr

100 ml

35:1

SiO2

Si3N4

metals

Etylenediamine

Pyrocathecol

Water

750 ml

120 gr

240 ml

1.25

35:1

SiO2

Si3N4

metals

115 °C

KOH

Water + Isopropyl

44 gr

100 ml

85 °C

1.4

400:1

SiO2

Si3N4

TMAH

Water + Isopropyl

220 gr

780 ml

90 °C

1.0

100:1

SiO2

Si3N4

115 °C

0.75

Slide 26

Chemistry of Anisotropic Etching

Etching phases:

► Transport of reactants to the silicon surface;

► Surface reaction;

► Transport of reaction products away from the surface.

Key etch ingredients:

► Oxidisers;

► Oxide etchants;

► Diluents and transport media.

Mechanism

–

2+

–

Si + 2OH → Si(OH)2 + 4e

–

–

4H2O + 4e → 4OH + 2H2 (gas)

2+

–

2–

Si(OH)2 + 4OH → SiO2(OH)2 +

2H2O

Overall:

–

Si + 2OH + 2H2O →

2–

→ SiO2(OH)2 + 2H2

(gas)

Slide 27

Anisotropic Etching of (100)-Si

Cavity defined by:

<110> Directions

{111} Planes

► {111} walls

BETCH

– slow-etching planes;

{111} Planes

► {100} floor

– fast-etching plane.

(100) Plane

Final shape of cavity

depends on:

► Mask geometry;

► Etching time.

Truncated Pyramidal

Cavity

Shape of cavity:

V-Groove

Cavity

N-LAYERS

► Truncated pyramid;

► V-groove;

► Pyramid.

OXIDE

P-SUBSTRATE

Slide 28

Pyramidal

Cavity

Cavity Geometry for (100)-Si

Anisotropically etched cavity in (100) silicon

with a square masking film opening oriented

parallel to the <110> directions.

Wb = W0 – 2·l·cot(54.7°)

Slide 29

Mask Undercutting

(a) is a pyramidal pit bounded

by the {111} planes.

(b) is a type of pit expected

from slow undercutting of

convex corners.

(c) is a type of pit expected

from fast undercutting of

convex corners.

In (d), further etching of (c)

produces a cantilever beam

suspended over the pit.

(e) illustratates the general rule

for undercutting assuming a

sufficiently long etching time.

<100>

<110>

Mask

<111>

(a)

Si

(b)

Si

(c)

Si

(d)

Si

(e)

Slide 30

Anisotropic Etching of (110)-Si

Cavity defined by:

► {111} walls

Mask

– slow-etching planes;

<111>

► {110} floor

– fastest-etching plane;

{100}

A

<111>

► {100} bottom side walls

– fast-etching planes;

Final shape of cavity

depends on:

{110}

70.5º

a)

<110>

Mask

<100>

► Mask geometry;

<111>

► Etching time.

Cavity shape:

► Rhombic prisms;

b)

45º

90º

► Hexahedric prisms.

Slide 31

A'

Cavity Geometry for (110)-Si

Slide 32

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 33

Methods for Selective Etching

Time etching methods:

► Calculate the needed etching time on the basis of the etching rate.

– Easy, but inaccurate method, as etching rate varies with the chemical condition of

the etchant and geometrical factors limiting the agitation of the etch.

Typical accuracy: ± 20 µm.

► Inspect the depth of the etched cavity in appropriate time intervals

until desired depth is reached.

– Time consuming, but improved accuracy. Uneven etching depth from cavity to

cavity due to chemical and geometrical factors is still a problem.

Typical accuracy: ± 10 µm.

Chemical selective techniques:

► The etching stops when a chemically resistive layer is reached.

– Typical accuracy: ± 3 µm.

Electrochemical selective techniques:

► The etching stops on reverse biased pn junctions.

– Typical accuracy: ± 1 µm.

Slide 34

Time-Stopped Etching

Example of etching stopped at an arbitrary depth, exhibiting a flat

floor.

Slide 35

Etching Stopped by {111} Walls

Example of etching stopped by the intersecting {111} walls,

exhibiting a pyramidal groove.

Slide 36

Boron Etch-Stop Technique

Chemical selective etching:

► Etch rate depends on boron

concentration.

► Etching stops if boron

concentration exceeds

5·1018 cm–3.

Boron stop layer is

manufactured:

► By diffusion deposition,

implantation or both;

► On the opposite surface of the

wafer with respect to the etch

cavity.

Boron-dependent etch rate of

silicon (from Seidel et al.)

Slide 37

Boron Etch-Stop Mechanism

Interstitial bonds require more energy to be broken.

The electrons supplied by the etchant recombine with the holes

in the bulk, rather than participating in the chemical reaction.

Interstitial

boron atom

Silicon atom

Substitutional

boron atom

Slide 38

Boron Etch-Stop Shortcomings

Electronics cannot be integrated in the boron stop layer.

► Solution: depositing an epitaxial layer atop the stop layer, with

appropriate doping as substrate material for integrated devices.

– Controlling the autodoping of the epi-layer is challenging.

n-type epitaxial layer

p+ type boron stop layer

n-type substrate

Slide 39

Electrochemical Etch-Stop (ECES)

Electrochemical selective etching:

► Etch rate depends on the applied

potential.

+

–

V

oxide

► Etching stops if the applied potential

exceeds a threshold value, called

passivation potential.

► Low-doped material, both p- and

n-type, can be passivated:

– To be used as substrate for integrated

components such as piezoresistors.

p

Pt

n p

etchant

stir bar

High accuracy, typically ± 1 µm:

► Achieved by using well-controlled

implantation and diffusion techniques.

KOH and TMAH can be used:

– Both avoid the health dangers of EDP.

Slide 40

Wafer Holder for ECES

A practical way to make a wafer

holder to be used for electrochemical selective etching.

The principles for industrial

manufacturing equipment

are the same.

Slide 41

Electrochemical Etch-Stop Mechanism

Etch-stop achieved by reverse biasing the pn junctions.

More in the Bulk Silicon Etching tutorial...

+

P-layers

N-layers

Vp

Etch

Rate

Silicon Etching

Anodic Passivation

Vn

Vpp

V

Slide 42

ECES for MultiMEMS

Electrochemical etch-stop allows 3 different thicknesses:

► Full-wafer thickness (400 µm)

For heavy seismic masses;

► Epi-layer thickness (3 µm)

For thin membrane, springs;

► N-well thickness (23 µm)

For thick membranes, masses, bosses…

Slide 43

Etch-Stop on Multi-Level Junctions

Very Thin Membrane

Thick Membrane

(Mass/Well)

Thin Membrane

Slide 44

Outline

1. Background and Motivation

2. The Silicon Crystal

3. Isotropic Wet Etching

4. Anisotropic Wet Etching

5. Selective Etching

6. Convex Corners

Slide 45

Undercutting of Convex Corners

High etch-rate of high-index planes:

► Severe undercutting of convex corners;

► Truncated pyramids or V-grooves as final cavities.

Mask will be undercut until

{111} planes are exposed.

undercut

Mask

{100}

{221}

{111}

{111}

Slide 46

Compensation for Convex Corners

Etching without corner

compensation structure

Etching with corner

compensation structure

Corner compensation of mask is difficult

to establish as a repeatable process;

highly dependant on etching

parameters.

Corner Compensation in Silicon

(from Gupta et al.)

Slide 47

Corner Compensation Structures

Compensation

Structure

Desired Result

A simple approach

to convex corner

compensation

(from Wei Fan et al.)

Slide 48

Designing with Undercut Corners

Fabrication of MEMS - MEMS Technology Seminar

(from Burhanuddin Yeop Majlis)

Slide 49

Thank you

for your attention !

Slide 50