Details here

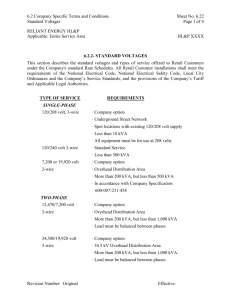

advertisement

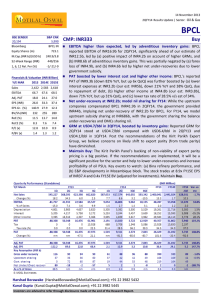

INDUSTRIAL TRAINING BRIEFING BHARAT PUMPS & COMPRESSORS LTD By Mritunjay Yadav M110066EE INTRODUCTION A Public Sector Undertaking under the control of Ministry of Heavy Industries & Public Enterprises, Govt. of India. BPCL was incorporate in 1970. BPCL is a Mini Navratna Company. Details of all the employees are maintained by company Designation Strength Executive 188 Supervisor 58 Non Executive 810 TOTAL 1056 PROFIT & LOSS ACCOUNT FOR THE YEAR ENDED 31ST MARCH,2011 (in Lacs) Turnover (Net) 20801.47 Expenditure 18899.34 Profit before Tax and Prior Period Adjustment 1926.60 Profit after Tax 1120.78 Balance of PROFIT carried to Balance Sheet 5768.98 Products: 1: Pumps and Compressors Centrifugal Pumps Pumps for Application in Power Plants. Reciprocating Piston and Plunger Pumps. Reciprocating Compressors. 2: Gas cylinders Gas Cylinders High Pressure Seamless Industrial Gas Cylinders. Welded Cylinders. Cylinders in Cascade for Storage of Compressed Natural Gas (CNG) Maximum Pressure 400 kg/cm2 Maximum Capacity 110 Litres. Fluids Handled Oxygen, Nitrogen, Hydrogen, Argon, Air, Helium, Carbon Di-Oxide, Nitrous Oxide, Acetylene, Ammonia, Chlorine, Freon, LPG, Compressed Natural Gas Cylinder plant Sample enter Doming Bottom Forming Neck Formation Heat Treatment Machine Operation Hydro Test Air Leakage Testing Painting End COLOR CODING GAS COLOR Oxygen black Carbon dioxide black (neck) + white (body) Hydrogen Red Air green Hot spinning Machine EN 500 Some of the outstanding features of EN 500 include: Fully integrated induction heating furnace with automatic load and unload Integral loading and unloading tables for easy and fast load and unload. Machine center line aligned with induction heater coil transfer line to optimize auxiliary times Simple and very efficient loading and transfer Servo CNC controlled transfer and loading system Energy fail-free high force work-piece clamping system with normally closed gas cylinders for work safety Centrifugal Pumps A centrifugal pump adds kinetic energy to a fluid by means of fast-rotating impellers. Its accelerated velocity is converted into pressure head by exiting into the diffuser for discharge Maximum Power 2500 KW Maximum Pressure 140 kg/cm2 Maximum Capacity 12,000 M3/Hr Fluids Handled Demineralised water, Sea water, Hydrocarbons, Naphtha, LPG, Carbonate Solution, Boiler Feed Water, Benfield solution, Alkaline and Acidic Solution, Ammonia liquor and slurry DESIGN ASPECTS OF CENTRIFUGAL PUMPS •Pump casing •Lower half casing •Rotating elements •Top half casing •Impellers Reciprocating Pumps • utilizes a crankshaft-connecting rod mechanism identical to internal combustion engines. • The crankshaft-connecting rod mechanism converts the rotary movement of the crankshaft to a reciprocating linear movement of plungers or pistons. Maximum Power 1700 HP Maximum Pressure 675 kg/cm2 Maximum Capacity 315 M3/Hr Fluids Handled Drilling Mud, Cementing Slurry, Crude Oil steam, Condensate, Heavy Water, Fatty Acids, Ammonia Carbonate, Liquid Ammonia, Water Injection Reciprocating Pumps Reciprocating Compressors Maximum Power 4,000 KW Maximum Pressure 450 kg/cm2 Maximum Capacity 70,000 NM3/Hr Fluids Handled Air, Nitrogen, Oxygen, Carbon Di-Oxide, Hydrocarbons, Ammonia, Synthesis Gas, Hydrogen Sulphate, Coal Gas etc. MACHINES IN PUMP AND COMPRESSOR PLANT Vertical Boring Machine (BV -2500) Plano Milling (Pm-1600) Horizontal Borer (Bft-125) Cylindrical Grinder (Bua-630) Radial Drill Honning Machine Centre Lathe (Nh22) Horizontal Milling Machine Energy analysis : Contracted demand – 2000 Tariff –HV2 current max demand -1156 Last month -1696 Last month energy – 309960.00 Demand charge 1680 230 kVA/mth 386400 TOD-1(22-06) Energy charges 31860 4.25 kVA/h 135564.30 TOD-2(06-17) Energy charges 182700.00 4.60 kVA/h 840420.00 TOD-3(17-22) Energy charges 51900.00 5.29 kVA/h 274551.00 1636935.00 POWER FACTOR 0.91 Misclleneous charges = 21826 (ELECTRICITY DUTY) Total = 1658762.10 Rs Bill for FEB 2012 Contracted demand – 2000 Tariff –HV2 current max demand -1495.620 Last month -1696 Last month energy – 309960.00 Demand charge 1740 230 kVA/mth 400200.00 TOD-1(22-06) Energy charges 47280.00 4.25 kVA/h 201176.30 TOD-2(06-17) Energy charges 224640.00 4.60 kVA/h 1033344.00 TOD-3(17-22) Energy charges 95280.00 5.29 kVA/h 504031.20 2138751.00 • Power factor = 0.889 • Miscellaneous charges = 29408 (Electricity Duty) • Total = 2168160.00 Rs CUSTOMER OF BPCL : Oil & Natural Gas Commission. Indian Oil Corporation. Hindustan Petroleum Corporation. Fertilizer Corporation of India Ltd. Indian Farmers Fertilizer Corporation. Gas Authority of India Ltd. Indian Petro-Chemicals Ltd. Madras Refineries Ltd. Oil India Ltd. BRANCHES OF BPCL Its manufacturing unit is at Allahabad only. But it has 6 more branches atDelhi Mumbai Kolkata Chennai Dibrugarh (Assam) Baroda (Gujrat) OBSERVATION & SUGGESTION OBSERVATION Very few Export - Orders are there . Lack of Aggressive marketing is there Delivery performance of BPCL is very poor Huge Time – Lag in procurement of raw materials SUGGESTIONS: BPCL- should have export division. Better IT networking and communication Training and development should be considered. Research and development programmes should be initiated. BPCL should make list of fast moving equipments. Better medical facilities should be provided inside the campus. Thank You