(theoretical yield/total mass of all reactants) X 100

advertisement

29 papers of Perkin Transactions1 (year 2000)

-31% chlorinated solvents

-35% dipolar aprotic solvents such as D/MF

-24% noxios solvents such as benzene and pyridine

-one paper water as the solvent

•Transportation – production of gasoline and diesel from petroleum,

•Transportation – production of gasoline and diesel from

fuel

additives for greater efficiency and reduced emissions, catalytic

petroleum,

converters,

plastics

to reduce

vehicleand

weight

and improve

energy

fuel additives

for greater

efficiency

reduced

emissions,

catalytic

efficiency.

converters,

plastics tofibres

reduce

vehicle

weight

improve

•Clothing

– man-made

such

as rayon

andand

nylon,

dyes,energy

waterproofing

efficiency.

and

other surface

finishing

chemicals.

•Clothing

– man-made

fibres

such as rayon and nylon, dyes,

water-proofing

•Sport

– advanced composite materials for tennis and squash

rackets,

and other surface finishing chemicals.

all-weather

surfaces.composite materials for tennis and squash

•Sport – advanced

rackets,

all-weather surfaces.

•Safety – lightweight polycarbonate cycle helmets, fire-retardant

•Safety – lightweight polycarbonate cycle helmets, fire-retardant

furniture.

furniture.

•Food – refrigerants, packaging, containers and wraps, food

•Food – refrigerants, packaging, containers and wraps, food processing

Processing aids, preservatives.

aids, preservatives.

•Medical – artificial joints, ‘blood bags’, anaesthetics, disinfectants,

•Medical – artificial joints, ‘blood bags’, anaesthetics, disinfectants,

anti-cancer drugs, vaccines, dental fillings, contact lenses, contra-ceptiv

anti-cancer drugs, vaccines, dental fillings, contact lenses, contra•Office

– photocopying toner, inks, printed circuit boards, liquid-crystal

ceptives.

displays.

•Office – photocopying toner, inks, printed circuit boards, liquid-crystal

•Home

– material and dyes for carpets, plastics for TVs and mobile

displays.

phones,

videoand

anddyes

audio

paints,

detergents.

•Home –CDs,

material

fortapes,

carpets,

plastics

for TVs and mobile

•Farming

fertilizers,

pesticides.

phones, –CDs,

video and

audio tapes, paints, detergents.

•Farming – fertilizers, pesticides.

THE TWELVE

PRINCIPLES OF GREEN

CHEMISTRY

1. It is better to prevent waste than to treat or clean up

waste after it is formed

Chromare & Nitrite corrosion inhibitor

Cerium corrosion inhibitor

Common fertilizer(P+N)

Soya base fertilizer(N 7% )

Cl Cl

Cl

Cl

O

O

Cl Cl

O

Cl

O

Cl

2,3,6,7 -tetrachlorodibenzo-4-dioxin

2,3,6,7 -tetrachlorodibenzo-4-dioxin

TCDD

TCDD

-Because

of low polarity of dioxins and furans, like many

other organochlorine compounds, are far more soluble in the

fatty tissues of animals than they are in water.

-When these compounds enter the animal they are not readily

exerted and tend to accumulate in fatty tissues that we call it

bioaccumulation.

-So can result in an animal having significantly higher

concentrations of the organochlorine compound in its body

than in the surronding environment .

-At each higher level of the food chain there is an increasing

concentration of the contaminant.This is known as

biomagnification.

-The combined effects of bioaccumulation and

biomagnification can make the contaminant levels in fish up

to 100000 times greater than that of their suuronding

environment.

TAML ACTI

VATOR

H

H

O

O

O

X

N

N

R

N

R

FeIII

X

N

O

O

Cat+=Li+, [Me4N]+, [PPh4]+

X= Cl, H,OCH3

2. Synthetic methods should be designed to maximize the

incorporation of all materials used in the process into the final

product.

The classic evaluation of effectiveness and efficiency of a

synthesis is yield. Yield also totally ignores the use or generation

of any undesirable products that are an intrinsic part of

synthesis.. It is possible and very often the case that a synthetic

pathways, or even a synthetic step can achieve 100% and

generate waste that is greater in mass and volume than that of

the desired product.

The standard synthetic transformation types can be evaluated

generically to determine the intrinsic atom economy of each type.

1) Rearrangement

Trans

Cis

2) Addition

C==C

+ A-B

C

3) Substitution

C

A

C

+ D

B

4) Elimination

C

A

C

B

C==C

C

A

B

C

C

A

D

Efficiency of a Reaction

Percentage yield= (actual yield/theoretical

yield) X 100

Topic: Atom Economy

• A Measure of the Efficiency of a

Reaction and is an assessment in

which one looks at all of reactants

to measure the degree to which

each of them is incorporated into

the final product.

ATOM ECONOMY

“Because an Atom is a Terrible Thing to Waste”

• How many of the atoms of the reactant are

incorporated into the final product and how

many are wasted? Infusing green chemistry

into organic.

Atom Economy in a

Substitution Reaction

Equation 1b

H3C CH2 CH2 CH2

1

OH + Na

2

Br

+ H2SO4

3

H3C CH2 CH2 CH2

4

Br + NaHSO4 + H2O

5

6

Equation 1a

CH3CH2CH2CH2OH + NaBr +

1

0.08g

0.0108mole

2

1.33

0.0129

H2SO4

3

2.0

0.0200

CH3CH2CH2CH2Br + NaHSO4 + H2O

4

5

1.48 g (theoretical yield)

0.0108 mole (theoretical yield)

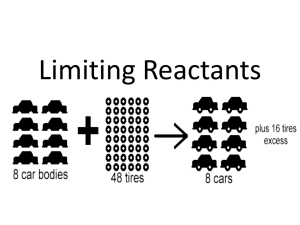

Compound 1 is the limiting reagent

Suppose the actual yield is 1.20 g of compound 4.

Percentage yield= (actual yield/theoretical yield) X 100

= (1.20 g/1.48 g) X 100 = 81%

6

% Atom Economy = (FW of atoms utilized/FW of all reactants) X 100

= (137/275) X 100 = 50%

Table 4

Experimental Atom Economy of Equation 1: Based on

Actual Quantities of Reagents Used

% Experimental Atom Economy = (mass of reactants utilized in the desired product/total mass of all reactants) X 100

= (theoretical yield/total mass of all reactants) X 100

= (1.48 g/4.13 g) X 100 = 36%

% Yield X Experimental Atom

Economy

% Yield X Experimental Atom Economy =

(actual yield/theoretical yield) X (mass of

reactants utilized in the desired product/total

mass of all reactants) X 100

%PE .EAE= (actual yield/theoretical yield) X

(theoretical yield/total mass of all reactants)

X 100 = (actual yield/total mass of all the

reactants) X100

= (1.20 g/4.13 g) X 100 = 29%

Percentage yield= (actual yield/theoretical yield) X 100

= (1.20 g/1.48 g) X 100 = 81

% Atom Economy = (FW of atoms utilized/FW of all reactants) X 100

= (137/275) X 100 = 50%

% Experimental Atom Economy = (mass of reactants utilized in the desired

product/total mass of all reactants) X 100

= (theoretical yield/total mass of all reactants) X 100

= (1.48 g/4.13 g) X 100 = 36%

%PE .EAE= (actual yield/theoretical yield) X (theoretical yield/total mass of all

reactants) X 100 = (actual yield/total mass of all the reactants) X100

= (1.20 g/4.13 g) X 100 = 29

GREEN CHEMISTRY

• The Synthesis of Ibuprofen

– Advil, Motrin, Medipren

– 28-35 million pounds of ibuprofen are

produced each year (37-46 million pounds of

waste)

Since about 15 million kg of ibuprofen are

produced each year, this translates into more

than 17.5 million kg of waste generated each

year from the synthesis of ibuprofen!

The Boots Synthesis of Ibuprofen

Atom Economy

% Atom Economy = (FW of atoms utilized/FW of all reactants) X 100

= (206/514.5) X 100 = 40%

The BHC Synthesis of Ibuprofen

Atom Economy

% Atom Economy = (FW of atoms utilized/FW of all reactants) X 100

= (206/266) X 100 = 77%

3. Wherever practicable, synthetic methodologies should be

designed to use and generate substances that possess little or no

toxicity to human health and the environment

Ni-Al2O3

Co-CO2

370-800psi

120-140psi

OH

O

Ni-Al2O3

+

370-800psi

H2OC

CO2H

OH

CO2H

OH

E.Coli

E.Coli

OH

OH

O

OH

OH

CO2H

H2OC

OH

H2 Pt

370-800

H2OC

CO2H

CN

3HC

O

+

3HC

CH3

O

R

CN

K2CO3

+ CH3OH + CO2

O

R

LD50 &LC50.

LD and LC stand for lethal dose and lethal concentration respectively.

LD50 is the dose of a chemical at which 50% of a group of animals

(usually rats or mice) are killed, whilst LC50 is the concentration in air

or water of the chemical which kills 50% of test animals. These tests are

the most common ways of measuring the acute toxicity of chemicals.

LD50 tests are done by injecting, applying to the skin or giving orally a

known dose of pure chemical. The result is usually expressed in terms of

milligrams of chemical per kilogram of animal, e.g. LD50 (oral, rat) –10

mg kg –1 means that when given orally at the rate of 10 mg kg -1animal

weight the chemical will kill 50% of rats tested.

Similarly LC50 tests are usually carried out by allowing the animal to

breathe a known concentration of the chemical in air, results being

expressed in parts per million(ppm) or milligrams per cubic metre (mg

m3).

4. Chemical products should be designed to preserve efficacy of

function while reducing toxicity.

The balance btwn maximizing the desired performance and function of

chemical product while ensuring that the toxicity and hazard is reduced

to its lowest possible level is the goal of designing safer chemicals

CH2CH2CN

CH3CHCN

OH

OH

rat oral LD50=1.23 mmol/Kg

rat oral LD50=45 mmol/Kg

R

R

R

R

CN

OH

+

O

HCN

Mechanism of action analysis:

Direct toxicity: Chemical substance itself that is reacting to cause the end

effect of concern

Indirect toxicity: it is metabolite or derivative of the original substance that is

responsible for harmful interaction with the body

.

R-CH-CN

R-CH2-CN

Me

R-C-CN

Me

SAR(structure activity relationships):

SAR are based on a correlation btwn the molecular architecture

of a compond and its activity

Avoid the use of functional group that posses some toxicity:

Isocyanate base adhesive

Acetoacetate esters

Mask the functional group that posses some toxicity

Vinyl solfone base dye

Vinyl solfone sulfatebase dye

Minimizing bioavailability:

The ability to enter the various biological systems and

organs is called bioavailability

Minimizing auxiliary substances:

Innocuous coating need to be dissolved in hazardous solvent

Coating with the same properties but can be used in aqueous systems

5. The use of auxiliary substances (e.g. solvents, separation agents, etc.) should be

made unnecessary whenever possible and, innocuous when used.

1)Concern for solvents

2)Environment

3)Supercritical fluids

4)Solventless

5)Aqueous

6)Immobilized

7)Ionic Liq.

3)Supercritical fluids

CH2Br

HV

NBS

CO2[SC]

40 C

139 bar

AIBN

4hours

100%

CH2Br

CH3

HV

40 C

Br2

CO2[SC]

252 bar

K2CO3

5MIN

CH3

+

Br

75%

Minor Product

CO2 benefits

1)Nonflammable

2)Nontoxic

3)Chemically unreactive

4)Cheaply recovered byproduct from the production

of ammonia and from natural gas wells

5)It can be recovered, purified and reused

4)Solventless

O

O

O

O

-H20

+

R

R

O

OH

O

+

O

O

O

O

-

NH4 MeCO3

OH

R

O

OH

O

5)Aqueous

NNH2

+

O

H2O

220 C

N

H

Isomerization of geraniol

OH

OH

H2O

+

220C

OH

6)Immobilized

[

]

n

O

O

7)Ionic Liq.

Me

MeNCH2CH2OH + ZnCl

2

Me

Choline chloride

Ionic Liq.

•Good solvent for awide range of inorganic and organic materials

•Often composed of poorly co-ordinating ions and can therefore be

highly polar yet non co-ordinating

•No effective vapour pressure

•Liquid range of 300 ºC allowing tremendous kinetic control

•Thermally stable up to 200 ºC

•Their water sensitivity does not affect their industrial applications

•Immiscible with a number of organic solvents and provide nonaqueous polar alternatives for two phase systems

•Relatively inexpensive/easy to prepare

THE GREEN ASPECTS

1)The high solubility of ionic liquids implies that only small reactor

volumes are required thus reducing waste from synthetic processes.

2) Also since they are often composed of poorly co-ordinating ions there is

a great potential for very high recovery and hence recycling of the solvent.

3)The fact that they have no effective vapour pressure and a large liquid

range means that ionic liquids, even if used at high temperatures, do not

release harmful vapours thus reducing the amount of volatile organic

compounds released into the atmosphere.

.Perfect candidates for biphasic catalysis(cleaning up

fuel diesl and in chemical and pharmaceutical

industries)

. Battery electrolytes

. Catalyst solvent (hydrogenation with rhodium,

ruthenium and cobalt complexes, oligomerisation

with nickel complexes

. Bronsted and lewis acidity and superacidity

. Ranging from hydrophobic to hydrophilic

.Water sensitive to air stable

. Cheap and straight forward to prepare

6. Energy requirements should recognized for their environmental

and economic impacts and should be minimized. Synthetic

methods should be conducted at ambient temperature and

pressure.

1)Separation.energy.requirements

2)Microwaves

3)Sonic

4)Optimizing.the.reaction.should.mean.minimizing.the.energy.

Requirement

7. A raw material feedstock should be renewable rather

than depleting whenever technically and economically

practical.

1) What are renewable vs. depleting feedstocks?

2)

3)

4)

5)

6)

7)

a)

b)

Sustainability

Direct environmental effects

Indirect environmental effects

Limited supply creates economic pressure

The political effects of petroleum

Concern about biological feedstocks

Seasonal supply

Land/energy usage

8. Unnecessary derivatization (blocking group,

protection/deprotection, temporary modification of physical/chemical

processes) should be avoided whenever possible.

1) The prevalence of this practice in chemistry

2) Blocking/protecting groups

3) Making salts, etc. for ease of processing

4) Adding a functional group only to replace it

Cl

Cl

Cl2

HNO3

NO2

NH2

H2

NH

NO2

CATALYST

NH

NH2

+

+

+

-

{CH3}4N OH

-H2O

NO 2

NH2

H2

+

NH

NH

CATALYST

NH

-H2O

N

N

_

O

(CH3)4N +

O

_

_

O

(CH3)4N +

NH2

9. Catalytic reagents (as selective as possible) are superior to

stoichiometric reagents.

CH3CH2CH2CH2OH + NaBr + H2SO4

CH3CH2CH2CH2Br + NaHSO4 + H2O

This reaction is actually an acid promotion Rn not an acid catalyzed Rn.

This is a result of the fact that the sulfuric acid in this reaction is

required in stoichiometric, not catalytic amounts. As principle 9

indicates reagent used in catalytic amount are preferable to reagents

used in stoichiometric amounts. Since one mole of sulfuric acid is

required for the loss of every water molecules in this reaction. Then only

stoichiometric quantities of this reagent will suffice. However even if

stoichiometric amounts are used then recovery / recycling / reuse of

unwanted products should take place whenever this is feasible.

Significant strides have been made to develop rns that are promoted by

nontoxic and recoverable catalysts.

The role of catalysts is to facilitate a transformation that is desired

without being consumed as part of the rn and without being

incorporated in the final product. This facilitation can take several

different forms including:

1) Selectivity enhancement:

selective catalysis has been achieved to ensure that the

degree of rn that take place is controlled (e.g. mono

additions vs. multiple addition),

the site of rn is contolled (c-methylations vs. omethylations),

and the stereochemistry is controlled(e.g. R vs. S

enantiomer).

In green chemistry both starting material utilization is

enhanced and waste production is minimized.

2) Energy minimization

by lowering the Ea of a rn pathway, catalytic systems

not only achieve control, but also lower the emperatures.

That are necessary to effect a reaction. In large scale of

commodity chemical process, this energy balance issue

can be the single most important factor from both an

environmental and economic impact assessment point of

view.

In comparing catalytic versus stoichiometric process, the advantage of

catalysis is that, while a stoichiometric reagent will generate one mole

of product for every mole of reagent used, a catalysts will carry out

thousands , if not millions, of transformations before it is exhausted.

10. Chemical products should be designed so that at the end of their

function they do not persist in the environment and break down into

innocuous degradation products.

1) plastics

2) pesticides

3) just as you design for function, consider degradation as a

function

4) designing for biodegradability

Classification of groups based on the effect on biodegradation defined from literature

data

Negative group

Mono benzene

Amide

Derivatives

Acyclic

Compounds

Neutral group

NO2, X, SO3H,Quaternary

C, CF3,Tertiary Amine, CN,

2 Substituted (meta),

3-6 Substituted

NO , X, SO H, Quaternary

C, CF ,

Positive group

CH ,NH , OCH ,Ether,

COOH, OH, Ester,

Aldehyde, OThers

Ortho,para

CH ,NH ,OCH , Ether,

Tertiary Amine,CN

COOH, OH, Ester, Amide

Amide, Aldehyde

11. Analytical methodologies need to be further developed to

allow for real-time in-process monitoring and control prior to

the formation of hazardous substances

An area of focus within the analytical community now is to

develop methods and technology that allow the prevention

and minimization of the generation of hazardous substances

in chemical processes.

The development of process analytical chemistry for green

chemistry is based on the premise that ‘ you can not control

what you can not measure’. In order to effect changes on

process during their operation, you need to have accurate

and reliable sensors, monitors, and analytical techniques to

assess the hazards that are present in the process stream.

When these toxic substances are detected at even the

smallest trace levels it may be possible to adjust the

parameters of the process to reduce or eliminate the

formation of these substance. If the sensors are interfaced

directly with process controls, this hazard minimization may

very well be automated.

Another example of the use of process analytical

chemistry is in the monitoring of the progress of

reactions to determine their completion. In many cases,

chemical process require the continuous addition of

reagent until the reaction is complete. If there is a realtime, in – process monitor to allow determination of

completion, then the need for additional excess reagent

can be obviated and potentially hazardous substances

can be eliminated from use and will not find their way to

the waste stream.

12. Substances and the form of a substance used in a chemical

process should chosen so as to minimize the potential for chemical

accidents, including releases, explosions, and fires.

In some cases where the recycling of a solvent from a process

may have advantages from the perspective of pollution

prevention and release to the environment, it may also increase

the potential for a chemical accident or fire.

Approaches to the design of inherently safer chemistry can

include the use of solids or low vapor pressure substances in

place of the volatile liq. Or gases that are associated with the

majority of chemical accidents. Other approaches include

avoiding the use of molecular halogens in large quantity by

substituting reagents that carry the halogens to be transferred

in a more innocuous manner.

The utilization of ‘ just- in- time’ techniques involves the

generation and rapid consumption of hazardous substances

within a contained process.

RNH2

+

COCl2

RNCO + HCl

R'OH

R'OH

RNH2

+

CO2

RNCO + H2O

Monsato university

RNHCO2R

URETHANE

RNHCO2R

URETHANE

Process Used to Minimize or Eliminate Hazards in

theTeaching Lab

•Assess the reaction conditions, focusing on solvents and reagents first.

•Identify hazardous materials or inefficient procedures

•Modify the process and test efficacy of new procedure

•Evaluate the overall process for hazards and efficiency