Niobium Sputtered Havar Foils

advertisement

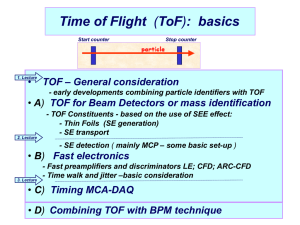

Niobium Sputtered Havar Foils for FDG Production R Johnson1, J Wilson, C Backhouse2, B Der, C Doerkson and S McQuarrie Edmonton PET Centre, 2 University of Alberta, Edmonton, AB, 1 Advanced Cyclotron Systems, Richmond, BC Canada Havar Limitations Introduction The Edmonton PET Centre currently supplies FDG to hospitals as far away as 1300 km. In order to meet this commitment in a tight multi run schedule, the production of 18F had to be maximized, while preserving the chemical environment within the water target so that the 18F could be subsequently used to provide FDG at high and reproducible yields. Although our niobium target was able to produce > 275 GBq (in a one hour irradiation) and operate with beam currents in excess of 100uA, subsequent FDG production yields were compromised. An ensuing study determined that the source of the problem was due to excessive metal ions coming from the Havar entrance foil and released into the water during irradiations that exceed 70uA. Our improvement on the design of a high-yield cyclotron target is involves facile sputtering of selected material onto traditional high strength metal foils used in cyclotron targets. We have recently successfully tested this concept. Ion Analysis on Irradiated 18 H2 O (48 hrs) Niobium Sputtered Foils - Cont. Havar foils are still the foil of choice for high pressure target applications due to its incredible strength and flexibility. However there are many limitations: • high radioactivation with proton beam currents • moderate heat conduction • formation of water soluble contaminants leading to problems with 18F reactivity The advent of new high current, low pressure water targets has lessened the need for the strength but increased the demand for non-reactivity in the very high temperature, caustic aqueous environment. It has been our experience that we are reaching the temperature capability limits of Havar as observed from pictures above. Side 2 niobium sputtered foil Sputtered Foils Many alternate materials with desirable properties for beam current applications are lacking the necessary strength to act as target foils. Sputtering a thin layer of an inert material onto Havar combines the properties of strength and flexibility with the advantage of non-reactivity. The sputtered metal is bonded very strongly to the Havar and acts as a foil of the pure metal. • • • • Havar foil activated trace metals in the target water arise from the constituent metals of Havar. Niobium foil Only 93Mo observed with niobium foil. (Scale is 1/10 of spectrum on left) Vacuum chamber ++++++++++++++++ Havar Foils - Post Production Substrate Sputtered atoms + V Ar plasma _ Ar+ Ar e- Target ---------------- 2042 uA hr Side 1 (broad beam spot) 13200 uA hr We found that the niobium sputtered foils produced more consistent 18F quality. Havar foils degraded over time which was not observed with the niobium foils. There is no indication that beam current limits have been reached with the niobium sputtered foils whereas the Havar shows serious breakdown under similar current conditions. Niobium was chosen for our initial trial as it has: excellent high temperature heat characteristics inert to fluoride very high m.p. only radioactive by-product 93Mo t1/2 = 6.9 hr Sputtering Process Conclusions Sputtering is a process for depositing a thin film of a material (the target) onto a substrate. 1. A high voltage (~500V) is applied between target and substrate to establish strong electric field. 2. Free electrons accelerated by electric field collide with introduced Ar gas atoms, ionizing them into Ar+ and freeing more electrons. Heavy Ar+ ions are in turn accelerated by the electric field towards the target, causing atoms of the target material to be sputtered (ejected) upon collision. 3. The sputtered target atoms get deposited on the substrate, forming a thin film of the target material. A vacuum environment is required for purity of the thin film and a long mean free path of the sputtered material. 4. In magnetron sputtering, a magnetic field is set up to confine electrons to the region around the target in order to improve sputtering efficiency and performance Further Steps Further experiments can be run using a variety of different materials other than niobium. Heat modeling can also be used to provide theoretical prediction to the thermal performance of sputtered foils before actual tests. Heat Model X-Y axis (cm) Time duration: 2hours Beam specifications: 16.5MeV, 100mA Model Specifics: No water cooling or evaporation of water Niobium Sputtered Foils – Post Production Acknowledgements 569 uA hr Side 2 (tight beam spot) 1223 uA hr Side 1 niobium sputtered foil after 5585 uA hr National Institute for Nanotechnology Alberta Cancer Foundation