Thermax ® in Rubber Applications

advertisement

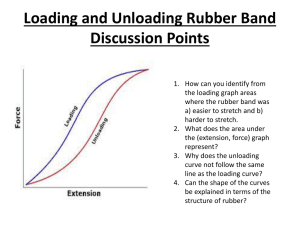

1 Cancarb April 8, 2015 Overview • Thermax® Thermal Carbon Black • Thermax® vs. Furnace Black • The Thermax Advantage • • • • • • • • • • 2 Natural Rubber Nitrile Rubbers Hydrogenated Nitrile Polychloroprene Fluoroelastomers NBR/PVC Blends Ethylene Propylene Rubbers Chlorosulfonated Polyethylene Rubbers – CSM Butyl and Halobutyl Rubbers Questions & Answers Cancarb April 8, 2015 Thermax® • Carbon black can be broadly defined as very fine particle aggregates of carbon, possessing an amorphous quasigraphitic molecular structure • The most significant areas of distinction between thermal black and furnace black are particle size and structure • Thermax®, thermal carbon black, due to its higher particle size (280 nm) and lower structure, compared to even the most coarse furnace black, can be translated into excellent rubber compound properties 3 Cancarb April 8, 2015 Thermax® vs. Furnace Black Grades Particle Size Diameter N762 (80nm) 4 Cancarb April 8, 2015 N990 (280nm) Thermax® vs. Furnace Black Grades Low Structure Moderate Structure High Structure N990 N762 N550 5 Cancarb April 8, 2015 The Carbon Black Spectrum OAN (DBP) ABSORPTION (ml/100g) INCREASING STRUCTURE 140 N343 N650 120 N550 N121 N339 N220 N539 N110 N330 100 N660 80 N774 N762 60 40 N326 N990 20 0 0 10 20 30 40 50 60 70 80 90 100 110 120 NITROGEN SURFACE AREA (m2/g) DECREASING PARTICLE SIZE 6 Cancarb April 8, 2015 130 140 150 160 Influence of Carbon Black on Properties Rubber Property Mixing temp. Dispersion Viscosity Green Strength Extrusion Quality Scorch Safety 7 Cancarb April 8, 2015 As Particle size Increases As Structure Decreases Influence of Carbon Black on Properties Rubber Property Tensile Elongation Hardness Tear resistance Compression set Heat build up Abrasion resistance Resilience 8 Cancarb April 8, 2015 As Particle size Increases As Structure Decreases The Thermax® Advantage The properties of Thermax® can be translated into rubber compounds with: • Lower heat build-up, especially during extrusion, which is very important for halogen bearing rubbers and high hardness compounds • Low hysteresis loss in dynamic applications, for example; automotive engine mounts • Reduced volume swell in aggressive fluids • Reduced cost • Low compound viscosity which is essential for injection molded and sponge compounds 9 Cancarb April 8, 2015 Natural Rubber (NR) Natural Rubber Structure CH3 • Natural rubber is polyisoprene – CH2 – C = CH – CH2 – • There are four possible isomers of natural rubber cis–1,4 Isomer -CH2 CH2C=C CH3 10 H Cancarb April 8, 2015 • 1,4 structure means that ‘C’ atoms 1 and 4 are joined in forming the chain • In the cis-1,4 structure both carbon atoms 1,4 forming the chain are on the same side of the double bond Natural Rubber (NR) • Natural Rubber has outstanding mechanical properties and fatigue resistance making it a very popular choice in dynamic applications • Natural rubber consists of polymer chains all having almost 100% perfect cis–1,4 structure. The true chemical name for this polymer is in fact, cis-1,4-polyisoprene • When the units in a macromolecule all consist of the same molecule, the polymer is said to be stereo regular 11 Cancarb April 8, 2015 Properties of Natural Rubber (NR) Natural Rubber: • Crystallizes on stretching, resulting in: • high gum tensile strength • high tensile strength/elongation @ break • very high tear strength & hot tear resistance • excellent De Mattia cut growth resistance • Gives a glass transition temp (Tg) of approximately -75°C • Has high resilience • Has excellent tack & green strength properties • Imparts low damping (hysteresis) and low heat build-up in dynamic deformation • Is unsaturated (double bonds), resulting in poor resistance to: • Heat aging • Ozone • Oils and hydrocarbons 12 Cancarb April 8, 2015 Applications of Natural Rubber Common Applications of Natural Rubber are: • Truck tire tread (Tear, hot tear, low heat build-up) • Passenger radial (Flexibility, low heat build-up) • Anti-vibration (Dynamic deformation) • Conveyor belting (High mechanical properties, tear) • Adhesive tapes and solutions (Tack) 13 Cancarb April 8, 2015 The Thermax® Advantage in Natural Rubber Compounds • Thermax® maintains the inherent good properties of the natural rubber polymer dynamic • The best choice for anti-vibration applications • Thermax® lowers compound hardness while retaining the good tack properties inherent to natural rubber • Excellent for cushion gum compounds • In wiper blade applications, higher loadings of Thermax® lower the rubber content of the compound which is essential for low noise and a good surface finish. 14 Cancarb April 8, 2015 NR Compound Example Using Thermax® Natural Rubber Engine Mount SMR Zinc Oxide Stearic acid A.O. TMQ N 762 Thermax N990 Aromatic Oil CBS TMTD Sulfur 100 3 1 1.5 15 45 15 3 0.5 0.5 100 3 1 1.5 15 70 15 3 0.5 0.5 Cure time @ 160°C Hardness Tensile strength Elongation @ Break % 11‘ 43 206 535 11‘ 49 178 480 Dynamic testing at 20 Hz Tan Delta at 25°C 0.084 0.027 15 Cancarb April 8, 2015 Nitrile Rubber (NBR) Nitrile Structure butadiene - CH2 - CH = CH - CH2 - + acrylonitrile - CH2 - CH CN Polymer Unit - (CH2 - CH = CH - CH2)n - 16 Cancarb April 8, 2015 CH2 - CH ( ) CN - m Nitrile Rubber (NBR) • Nitrile rubbers are high molecular weight copolymers of 1,3-butadiene and acrylonitrile • The percentage of acrylonitrile content can be varied from 18% to 50%, and will influence the performance characteristics of the polymer • The great variation in acrylonitrile content possible with nitrile rubber, allows for compounds to be customized to highlight specific required properties 17 Cancarb April 8, 2015 Nitrile Rubber – Effect of Acrylonitrile Content Increases Density Processability Cure rate – Sulphur Cure System Oil/fuel resistance Compatibility with polar polymers Thermoplasticity Stiffness Tensile As ACN Increases Abrasion resistance Heat – aging resistance Decreases Resilience Cure rate – peroxide system Low temperature flexibility Air/gas permeability 18 Cancarb April 8, 2015 Nitrile Rubber – Effect of Mooney Increases Acceptance of fillers/plasticizers Incorporation time of fillers Mixing temp Sheet formation time on mill Mill shrinkage Green strength Modulus As Mooney Increases Decreases Porosity Compression set 19 Cancarb April 8, 2015 Properties of Nitrile Rubbers Nitrile Rubber: • Has very good oil and fuel resistance • Can perform over a wide temperature range • Has inherently good resistance to gas permeation which increases as the level of acrylonitrile increases • Can be blended, up to 50%, with polyvinyl chloride (PVC) to produce compounds that exhibit good weathering characteristics in addition to good dynamic properties • Can be co-polymerized with methacrylic or acrylic acid to produce carboxylated nitrile (XNBR), which is noted for its excellent dynamic properties and abrasion resistance 20 Cancarb April 8, 2015 Applications of Nitrile (NBR) Common Applications of Nitrile Rubber are: • Gaskets and seals – NBR, XNBR (for high hardness) • Hoses – NBR (mainly in tubes), NBR/PVC (mainly in covers) • Belting – NBR • Rollers – NBR, XNBR (for high hardness) • Cable Jackets – NBR/PVC • Textile (spinning cots/aprons) – NBR, NBR/PVC, XNBR • Industrial footwear – NBR, NBR/XNBR blend, NBR/PVC sponge • Insulation – NBR/PVC sponge • Molded/extruded components for various industries & automotive • Fabric proofing – NBR • Milking inflation - NBR 21 Cancarb April 8, 2015 The Thermax® Advantage in NBR Compound Applications • Higher loadings are achievable with Thermax®, which reduces the rubber content enabling for lower swell in aggressive fluids • Gaskets and seals • Thermax® promotes good extrusion properties and low heat development, avoiding potential scorch problems. This is critical for high hardness compounds • Hydraulic hose tubing • Thermax® maintains the desired hardness of a compound while lowering the viscosity for effective blowing • NBR/PVC Sponge Insulation, hoses and soles 22 Cancarb April 8, 2015 Nitrile Compound Example Using Thermax® Hydraulic Hose (Broad Temperature Range) Nitrile Rubber ZnO St. acid Processing Additive A.O. Aminox A.O. ZMBI N550 N990 ageing Paraplex G-25 KP 140 Sulfasan R CBS TMTD Cure @ 166° SH / TS / EB Vol. swell % 100 (33-34% ACN, 75-80 Mooney) 5 1 2 2 (DPA + Acetone reaction product) 2 (Zn Salt of 2 – Mercaptobenzimidazole) 50 Suitable blend for good processing, 50 vulcanizate properties and good heat > Blend of polyester and phosphate 10 > plasticizers for resistance to heat extraction 10 and low temperature cracking 1 3 3 15' 70 / 152 / 270 19 (ASTM Oil 3 / 70h 135°C) Blending with Thermax N990 helps improve scorch safety during extrusion due to lower heat development. Higher filler loading improves over all extrusion properties and sealing with end couplings 23 Cancarb April 8, 2015 Hydrogenated NBR (HNBR) Hydrogenated nitrile rubber is based on NBR that has been chemically altered (hydrogenated), resulting in a much lower amount of unsaturation in the polymer backbone. HNBR exhibits significantly improved heat resistance, compared to NBR, while retaining excellent oil and fuel resistance. HNBR Range % Hydrogenation % ACN content ~ 85 to 99+ 17 to 50 24 Cancarb April 8, 2015 Mooney (ML 1+4 @ 100°C) 50 to 150 Comparison with NBR for 50 phr FEF compound-Peroxide cured HNBR+ 50 phr FEF 99+ % hydrogenation 38% ACN 55* Mooney NBR+ 50 phr FEF 38% ACN 50** Mooney Mooney (ML 1+4 @ 100°C) 43 86 Hardness (Shore A) 68 76 T.S. (M.Pa) 17.5 21.9 EB (%) 390 180 Tear Die C (KN/m) Comp. Set % (168h/150°C) 15 18 16.7 27 Abrasion (DIN mm3 loss) Air Ageing (168h/150°C) 145 260 Hardness +8 +17 T.S. (%) Nil Brittle EB (%) -30 Brittle The significant improvements in the properties of HNBR over NBR, especially in compression set & heat ageing, bring HNBR very close to specialty rubbers. *ML 1+4@125oC **ML 1+4@100oC 25 Cancarb April 8, 2015 Hydrogenated NBR (HNBR) HNBR* ACM FKM VMQ Tensile 1 3 3 7 Heat Resistance 3 3 1 1 Comp. Set 2 2 1 1 Low Temp 3 5 7 1 Gear Oil 1 1 4 7 ASTM Oil #1 1 3 4 7 Sour Gasoline 2 5 1 7 Rating:1 Best; 7 Worst *99+ % Hydrogenation 26 Cancarb April 8, 2015 Applications of HNBR • Timing belts (automotive) – ozone resistance, flexing • Power steering rotary shaft seals • ‘O’ rings • Oil well specialties • Rollers • Air conditioning hoses for cars 27 Cancarb April 8, 2015 The Thermax® Advantage in HNBR Compounds Applications • HNBR rubbers have inherently good mechanical properties and do not require a reinforcing black. Thermax® maintains the good mechanical properties of HNBR while lowering the compound viscosity which is essential for easy processing • Thermax® does not degrade the excellent compression set of the HNBR polymer • Higher loadings are possible with Thermax® resulting in lower polymer content which provides lower oil swell and a significant reduction in the overall compound cost • Thermax® allows for extrusion with lower heat build-up giving better scorch safety and further improved impermeability of HNBR 28 Cancarb April 8, 2015 HNBRLow Compound Example Compression SetUsing HNBR Seal Thermax® Low Compression Set Seal TORNAC A 38.55 (99.5% saturation) Thermax® N990 Plasticizer WB 300* ZnO Stearic acid Trigonox 101-45** TAIC ML 1+4 @ 100°C MS Mooney Scorch at 125°C Cure time at 180°C SH/TS/EB Air aging 150°C / 168H Compression Set 70 h / 150°C 100 50 5 5 1 8 3 70 >25 ‘ 9’ 60/146/235 +8/-3/-40% 12 Thermax® maintains good low compression viscosity/mold flow, allows for less polymer content, low swell, adequate tensile strength and excellent compression set *Mixture of Aliphatic / Aromatic polyesters ** 2,5 dimethyl – 2,5 bis (tert butyl peroxy) hexane (Akzo). 29 Cancarb April 8, 2015 NBR/PVC Blends • Both NBR and PVC are polar which makes them very compatible, typically a 70/30 ratio • NBR provides resistance to heat and organic fluids but has poor resistance to weathering and ozone due to unsaturation. • PVC provides resistance to weathering, ozone and aliphatic hydrocarbons oils • PVC also improves processing, reduced flammability and mechanical properties such as T.S., tears and abrasions 30 Cancarb April 8, 2015 Carboxylated NBR (XNBR) • Carboxylated NBR (XNBR) is a terpolymer NBR with acidic organic monomer (typically 1 & 7%) carboxylic acid as a third monomer • Reactions of ZnO and Carboxylic Acid result in a matrix with significantly increased mechanical properties, such as higher hardness, abrasion resistance and tear strength • Although sacrifice in processing (mill and mould sticking) scorch, resilience and low temperature resistance, product retains the basic properties of NBR (oil & fuel resistance) 31 Cancarb April 8, 2015 Applications • Gasket and Seals - mainly NBR, high hardness seals ex/ Mud Pump – XNBR • Hoses – NBR mainly in tubes, NBR/PVC bend mainly in cover • Beltings • Rollers – NBR, XNBR for higher hardness rollers • Cable Jackets – NBR/PVC blends • Textile – spinning cots/aprons, NBR, NBR/PVC, XNBR • Industrial Footwear – NBR, NBR/XNBR blend, NBR/PVC sponge soiling • Insulation – NBR/PVC sponge • Moulded/extruded components for various industries, automotive • Fabric proofing – protective coatings, NBR • Milking inflation – NBR, resistance to fat 32 Cancarb April 8, 2015 NBR/PVC Blend Example Using Thermax® Compound 1 Compound 2 Gasohol Resistant Hoses NBR/PVC Blend70/30 100 100 Sulphur 1.5 1.5 ZnO 5 5 St. acid 1.5 1.5 N550 25 30 Thermax® N990 45 60 DOP 23 30 A.O. ODPA 1.5 1.5 P. Wax 3 3 TMTM .5 .5 ML, 1+4@ 100°C 34 34 MS, t5 @125°C 23’ 22’ Cure Time @ 160°C 7.5’ 7.5’ SH/TS/EB 68/143/450 70/131/415 Comp. set 22 h/70°C 27 27 Ageing in M15 test fuel (FAM 85 – Methanol 15), 48h at 23°C Change -18/-59/-60/+47.8v -19/-27/-51/+39v High loading of Thermax® lowers the polymer content allowing for low swell in aggressive fuels, low compression set and good extrusion. 33 Cancarb April 8, 2015 Polychloroprene (CR) Polychloroprene Structure 2-chlorobutadiene CH2 = C – CH = CH2 trans-1,4 polychloroprene (88-92 %) -CH2 C=C Cl Cl Chloroprene (liquid) 34 H Cancarb April 8, 2015 CH2- Similar to trans-1,4 isoprene but, the ‘CH3’ group has been replaced by ‘Cl’ Polychloroprene (CR) • Polychloroprene is often called neoprene. Neoprene is, in fact, the trade name of Dupont Dow Elastomers polychloroprene product line • Polychloroprene has a structure similar to that of natural rubber except one of the methyl side groups is replaced by a chlorine atom and it is a trans-oriented molecule • Polychloroprene can be sulfur modified or mercaptan modified to provide specific desired properties 35 Cancarb April 8, 2015 Properties of Polychloroprene (CR) Polychloroprene Rubber: Crystallizes on stretching, allowing for: • High gum tensile strength; similar to Natural Rubber (NR) • Very good fatigue resistance • When sulfur modified, will provide: • Excellent fatigue resistance • Highly resilient compounds • High tear resistance • When mercaptan modified, will provide: • Better raw polymer stability • Good resistance to heat • Good resistance to compression set 36 Cancarb April 8, 2015 Applications of Polychloroprene Common applications of polychloroprene rubber are: • Adhesives – polarity-bonding • V-belts – tack and fire resistance • Timing belts – tack and fire resistance • Bellows – high flexibility • Automotive seals • Bridge bearing pads – good dynamic properties and ozone resistance • Wire and cable – resistance to abrasion, oil, flame and weathering resistance • Hose (especially covers) – good weathering resistance 37 Cancarb April 8, 2015 The Thermax® Advantage in Polychloroprene Rubber Compounds • Thermax® will not degrade the inherently mechanical properties of polychloroprene good • Thermax® lowers the compound viscosity which is essential for lower heat build-up during extrusion and good mold flow • Thermax® will maintain the good compression set of the polychloroprene rubber • Higher loading of Thermax® is possible resulting in a lower rubber content which decreases oil swell and reduces the compound cost 38 Cancarb April 8, 2015 Polychloroprene Compound Example Using Thermax® Wiper Blade Compound Neoprene WRT SMR CV 60 ZnO MgO Stearic acid Thermax® N990 SRF Paraffinic Oil DPG TMTD Sulfur 6 PPD TMQ MC Wax Hardness 60 40 5 4 2 40 20 2-3 0.5 0.5 1.0 1.5 1.5 2 60 High loading of Thermax® reduces the polymer content (cost savings) which helps for low noise and gives a “clean” product & surface finish 39 Cancarb April 8, 2015 Fluoroelastomers (FKM) Fluoroelastomer Structure - (CF2-CH2)X - (CF-CF2)Y - (CF2-CF2)Z CF3 VF2 Vinylidine Fluoride 40 Cancarb HFP Hexafluoropropylene April 8, 2015 TFE Tetrafluoroethylene Fluoroelastomers - FKM • Fluorocarbon elastomers are a very popular choice for difficult sealing applications • Fluoroelastomers are created by substituting fluorine for hydrogen on a carbon-based macromolecule • Unlike hydrocarbon rubbers, which are non-polar, presence of fluorine creates polar molecules the • Fluoroelastomers are expensive and difficult to process due to their relatively high molecular weight 41 Cancarb April 8, 2015 Properties of Fluoroelastomers Fluoroelastomers: • Can be compounded to provide high heat resistance and thermal stability • Have excellent oil & gasoline resistance • Have excellent hydrocarbon-based solvent resistance • Have very good impermeability • Are flame resistant • Are resistant to weathering • Have excellent compression set resistance • Are expensive • Tend to have high Mooney viscosities which accelerate heat buildup when mixing 42 Cancarb April 8, 2015 Applications of Fluoroelastomers Common applications of Fluoroelastomers are: • Automotive – Valve Stem Seals, Shaft Seals, ‘O’ Rings • Aerospace – ‘O’ Rings for Hydraulic, Lubricating and Fuel Systems • Oil Field – Packers & Blow-out Preventers • Industrial – Expansion Joints in Mines, Gaskets, Valve & Pump Linings • Hoses – Fuel Lines, Turbo Chargers, Bio-diesel 43 Cancarb April 8, 2015 The Thermax® Advantage in FKM Compound Applications • High loadings of Thermax® will not reduce the excellent compression set and low swell inherent to FKM • Excellent for ‘O’ ring and seal applications • The higher loading ability of impermeability of the compound Thermax® improves the • The best choice for fuel line hose veneer • The specific gravity of Thermax® is similar to that of FKM, so higher loading of Thermax allows for the same volume of compound to be produced while using less of the expensive FKM elastomer, without sacrificing the desired compound properties. • Overall compound cost reduction 44 Cancarb April 8, 2015 FKM Compound Example Using Thermax® FKM O-ring Compound 1 Dyneon FC 2176 Maglite D 100 3 100 3 Calcium Hydroxide SRF 6 20 6 - Compound 2 Thermax® N990 Press cure 10‘@177°C+Post cure 24hrs@260°C 30 Tensile Strength (psi) Elongation at Break (%) 2120 220 1970 290 Shore A Hardness Air Ageing 70 hrs/276°C 80 76 Tensile Strength (psi) Elongation at Break (%) 1695 330 1405 295 Shore A Hardness Compression set (%) 81 50 77 28 - Method B (0.139” O rings) 70 hrs/200°C Thermax® enables higher loading while maintaining adequate original mechanical properties with excellent ageing properties, compression set resistance and low swell 45 Cancarb April 8, 2015 Ethylene Propylene Diene Rubber (EPDM) Structure CH2 = CH2 Ethylene CH3 | + CH = CH2 + A Diene Monomer Propylene Diene Monomers Used in EPDM • DCPD - dicyclopentadiene • ENB - ethylidene nobornene • VNB - vinyl norbornene Typically, ethylene comprises 45% to 80% of the polymer with the diene making up 2.5% to 12%. 46 Cancarb April 8, 2015 Ethylene Propylene Diene Rubber (EPDM) Increasing the ethylene content in EPDM provides: • Improved cold green strength • Excellent theroplasticity which improves extrusion and mold flow characteristics • Increased filler and oil loading ability • Higher heat resistance • Good cured tensile strength properties But: • It is responsible for less building tack • It is more difficult to mix • Mill processing at low temperatures is difficult • Compression set and recovery in cold temperatures is poor • Flex resistance and elastic recovery are reduced 47 Cancarb April 8, 2015 EPDM – Molecular Weight Distribution EPDM Polymer can be produced with a range of Molecular Weight Distribution (MWD). High molecular weight distribution EPDM provides for: • Excellent hot green strength, important for shaping and continuous vulcanization • High collapse resistance critical for hollow extruded sections • Less porosity in extrudates • Excellent physical properties • Low compression set • Improved resilience • Facilitates oil and filler extension which improves the difficult processing characteristics common to high MWD polymers • Higher loading of filler for lower cost compounds 48 Cancarb April 8, 2015 Ethylene Propylene Diene Rubber (EPDM) Increasing the diene content of the polymer provides: • • • • • 49 Shorter cure times Higher resilience Higher modulus Lower compression set Cure compatibility with unsaturated rubbers Cancarb April 8, 2015 Properties of EPDM EPDM based rubber offers: • Excellent weather and ozone resistance • Excellent high & low temperature resistance • Excellent water and chemical resistance • Excellent dielectric properties But, • Poor resistance to oils and hydrocarbon solvents • Poor adhesion 50 Cancarb April 8, 2015 Applications of EPDM Rubber Automotive industry Extruded Profiles – solid and sponge • Hoses – Radiator and Heater • Seals and grommets • Appliance Industry • Washing machine parts – gaskets, elbows and hoses Construction Industry Glass profiles • Flooring • Membranes • Roofing • Electrical Industry • Low and Medium voltage cabling – cable jackets Chemical Industry Hoses • Seals • 51 Cancarb April 8, 2015 EPDM Compound Example Using Thermax® Automotive Moulded Sponge Keltan 512 ZnO St. Acid Benzoic acid Thermaxx® N990 Winnofil S (Coated pptd CaCO3) Sunpar 150 Vaselin TMTD MBTS Sulphur Benzene Sulphohydrazide Benzene 1,3 Disulphohydrazide 100 5 1 1 100 35 60 10 Rotor/Roll Release 2 2 2 3 3 ML 1+4@100°C Cure time 15’@160 Specific Gravity 19 0.52 Higher Loading reduces costs. Low compound Mooney helps efficient blowing, gives uniform cell structure 52 Cancarb April 8, 2015 Metallocene EPDM Technology • The introduction of EPDM in the world market produced by Metallocene Catalyst Technology has increased the scope for the usage of Thermal Black in these rubbers considerably • EPDM produced by Metallocene Catalyst Technology has very high molecular weight compared to traditional EPDM Rubbers produced from solution and suspension polymerization technology • EPMD Rubbers with Metallocene Technology are very difficult to process when compounded with furnace blacks alone. Blending Thermax in blend with the furnace black lowers the compound viscosity allowing for easy processing without a negative affect on mechanical properties 53 Cancarb April 8, 2015 The Thermax® Advantage in EPDM Compound Applications • High loadings of Thermax® can reduce the compound cost without sacrificing compression set and dynamic properties • Thermax reduces the compound viscosity which improves processing, blowing and molding properties • The very low grit level of Thermax maintains excellent surface finish and ensures a uniform cell structure in sponge applications. • The excellent dispersion of Thermax results in consistent heat transfer throughout the extrusion and uniform cooling 54 Cancarb April 8, 2015 Chlorosulfonated Polyethylene Rubbers (CSM) Structure - (CH2-CH2)x – (CH2-CH)y – (CH2-CH)z | | Cl SO2 | Cl Polyethylene, a low cost plastic, is chemically modified to a cross-linkable rubber, retaining some of the important properties of polyethylene such as chemical resistance and electrical properties This polymer is almost exclusively produced by DuPont Performance Elastomers under the trade name Hypalon®. On May 7th, 2009, DuPont announced that it will cease production of Hypalon® and completely exit the CSM business 55 Cancarb April 8, 2015 Properties and Grades of CSM Properties • Excellent resistance to weather, ozone, sunlight, oxidation, alkalies and acids • Good resistance to oil and gasoline • Good flame resistance, abrasion resistance • It is close to polychloroprene in most properties but superior in resistance to acids, alkalies, solvents, Ozone and oxidation with better color stability Grades • Depending on the Cl content, range 24% to 43%, ‘S’ content around 1%, varying Mooney • Increasing Cl content give oil and flame resistance 56 Cancarb April 8, 2015 Applications of CSM Rubbers Grade Cl content (%) Hypalon 40/40S 35 Hoses W&C Rolls Hypalon 45 24 W&C Low Temp. Applications Hypalon 48/48S 43 Excellent oil resistance low permeability to Freon Air Conditioner Hoses 57 Cancarb April 8, 2015 Mooney Viscosity ML 1=4 @ 100°C 56/45 37 78/62 Butyl Rubber (IIR) Structure CH3 | - CH2 – C | CH3 Isobutylene + CH3 | - CH2 – C = CH - CH2 - Isoprene Butyl Rubber is a copolymer of isobutylene and a small amount of Isoprene, typically around 2% Chlorobutyl (CIIR) and bromobutyl (BIIR) rubbers are produced in a similar manner, but with and additional halogenation stage required 58 Cancarb April 8, 2015 Properties of Butyl Rubbers • Presence of “bulky” isobutylene groups causes slow movement of the polymer chain which gives butyl rubber excellent impermeability to air, oxygen and water • -CH3 groups along the chains interfere with each other, reduce the speed with which the molecules • Low unsaturation makes Butyl more resistant to heat ageing and to attacks by acids, alkalis, oxidizing agents, ozone, water and steam, than general purpose polymers such as SBR, BR and NR • Butyl rubber is very similar in structure to polyisobutylene and has a similar glass transition temperature (Tg) of -70°C • Butyl has low resilience and very poor resistance to compression set, oil and hydrocarbon based solvents • Low unsaturation slows the compound cure rate and reduces Butyl’s compatibility with the more unsaturated rubbers such as NR, SBR and BR. Even small amount mixed in with these rubbers gives a disastrous effect on compound properties 59 Cancarb April 8, 2015 Halobutyl Rubber Isoprene Halobutyl CH3 | Add X2 -CH2-C=CH-CH2X=Cl or Br CH3 CH2 + | || - Minus H (-CH2-C-CH-CH2-) + (X ) (-CH2-C-CH-CH2-) + (HX) + | | X X • Virtually all halogenation takes place at the isoprene portions of the IIR Chains which represent approximately 2.0 mole% of the IIR Co-Polymer • Commercial chlorobutyls contain 1.1 to 1.3% weight of chlorine and bromobutyls contain 1.9 to 2.1% weight of Bromine • Stearic hindrance of the double bond favors substitution rather than addition, so most of the unsaturation is retained, although it is now largely isomerised 60 Cancarb April 8, 2015 Butyl versus Halobutyl Rubber Butyl rubber Chlorobutyl Bromobutyl Cure reactivity Compatibility with other unsaturated rubbers Tack Cure adhesion with other rubbers • Increased cure compatibility reduces the need for stringent precautions against contamination with other unsaturated rubbers • Flexibility and resistance to dry heat are almost identical for both Chloro and Bromobutyl rubber 61 Cancarb April 8, 2015 Permeability of Halobutyl Typical Tire Inner Liner Compound Permeablility rates at 65°C 100% NR 100% SBR HIIR/NR (60:40) 100% HIIR Air 8.3 6.8 3.1 1.0 Moisture 13.3 11.0 3.0 1.0 The excellent permeability of Halobutyl rubber makes it a very popular choice for tire inner liners 62 Cancarb April 8, 2015 Applications of Butyl and Halobutyl Rubber • Inner tubes for tires (IIR, HIIR) • Heat resistant conveyor belts (HIIR) • Tire Inner liners (HIIR) • Tank linings (HIIR) • Side Walls (HIIR) • Dampers/bridge bearing pads (IIR/HIIR) • Tire curing bladders (HIIR) • Adhesives/sealants (cross-linked IIR, HIIR) • Steam/Automotive Hoses (HIIR) • Pharmaceutical closures (HIIR) 63 Cancarb April 8, 2015 The Thermax® Advantage in IIR & HIIR Compound Applications • High loadings of Thermax® can reduce the overall compound cost without a significant loss in compound properties • The higher loading ability of Thermax® improves the impermeability of the compound by replacing polymer with impermeable filler • Thermax can raise the viscosity of the compound making it easier and less expensive to process • Improved adhesion can be achieved with Thermax® which is very important for inner liner and other rubber to rubber bonding applications. 64 Cancarb April 8, 2015 Questions & Answers 65 Cancarb April 8, 2015