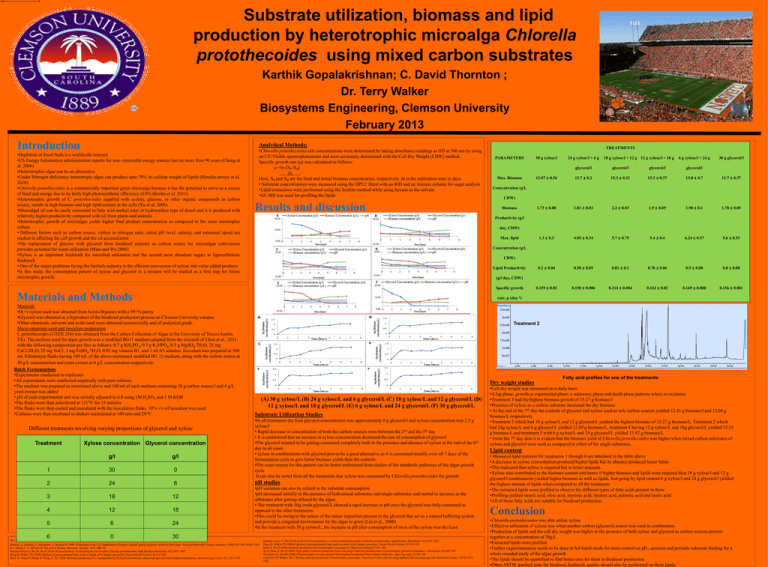

(A) 30 g xylose/L - Clemson University

advertisement

Substrate utilization, biomass and lipid production by heterotrophic microalga Chlorella protothecoides using mixed carbon substrates Karthik Gopalakrishnan; C. David Thornton ; Dr. Terry Walker Biosystems Engineering, Clemson University February 2013 Introduction Analytical Methods: •Depletion of fossil fuels is a worldwide concern •US Energy Information administration reports the non- renewable energy sources last no more than 90 years (Cheng et al. 2006) •Heterotrophic algae can be an alternative •Under Nitrogen deficiency heterotropic algae can produce upto 70% its cellular weight of lipids (Heredia-arroyo et al. 2010) •Chlorella protothecoides is a commercially important green microalga because it has the potential to serve as a source of food and energy due to its fairly high photosynthetic efficiency of 8% (Krohn et al. 2011) •Heterotrophic growth of C. protothecoides supplied with acetate, glucose, or other organic compounds as carbon source, results in high biomass and high lipid content in the cells (Xu et al. 2006) •Microalgal oil can be easily converted to fatty acid methyl ester or hydrocarbon type of diesel and it is produced with relatively higher productivity compared with oil from plants and animals •Heterotrophic growth of microalgae yields higher final product concentration as compared to the same autotrophic culture • Different factors such as carbon source, carbon to nitrogen ratio, initial pH level, salinity, and rotational speed are studied in affecting the cell growth and the oil accumulation •The replacement of glucose with glycerol from biodiesel industry as carbon source for microalgae cultivations provides potential for waste utilization (Miao and Wu 2006) •Xylose is an important feedstock for microbial utilization and the second most abundant sugars in lignocellulosic feedstock • One of the major problems facing the biofuels industry is the efficient conversion of xylose into value added products •In this study, the consumption pattern of xylose and glycerol in a mixture will be studied as a first step for future mixotrophic growth. •Chlorella protothecoides cell concentrations were determined by taking absorbance readings as OD at 540 nm by using an UV/Visible spectrophotometer and were accurately determined with the Cell Dry Weight (CDW) method. Specific growth rate (μ) was calculated as follows: µ =ln (Xf /X0) Δt Here, Xf and X0 are the final and initial biomass concentration, respectively. Δt is the cultivation time in days. • Substrate concentrations were measured using the HPLC fitted with an RID and an Aminex column for sugar analysis •Lipid extractions were performed using the Soxhlet method while using hexane as the solvent •GC-MS was used for profiling the lipids Results and discussion TREATMENTS PARAMETERS Max. Biomass 18 g xylose/l + 12 g 12 g xylose/l + 18 g 6 g xylose/l + 24 g 30 g glycerol/l glycerol/l glycerol/l glycerol/l glycerol/l 12.07 ± 0.56 12.7 ± 0.2 15.3 ± 0.21 13.3 ± 0.37 13.8 ± 0.7 12.7 ± 0.37 1.73 ± 0.08 1.81 ± 0.03 2.2 ± 0.03 1.9 ± 0.05 1.98 ± 0.1 1.78 ± 0.05 1.3 ± 0.3 4.05 ± 0.34 5.7 ± 0.75 5.4 ± 0.4 6.24 ± 0.57 5.6 ± 0.53 0.2 ± 0.04 0.58 ± 0.05 0.81 ± 0.1 0.78 ± 0.06 0.9 ± 0.08 0.8 ± 0.08 0.159 ± 0.01 0.158 ± 0.006 0.214 ± 0.004 0.162 ± 0.02 0.169 ± 0.008 0.156 ± 0.001 CDW) Biomass Productivity (g/l day, CDW) Max. lipid Concentration (g/l, CDW) Lipid Productivity (g/l day, CDW) Materials and Methods rate, µ (day-1) Materials •D(+)-xylose used was obtained from Acros Organics with a 99+% purity •Glycerol was obtained as a byproduct of the biodiesel production process on Clemson University campus •Other chemicals, solvents and acids used were obtained commercially and of analytical grade. Micro-organism used and inoculum preparation C.protothecoides (UTEX 256) was obtained from the Culture Collection of Algae at the University of Texas (Austin, TX). The medium used for algae growth was a modified BG11 medium adapted from the research of Chen et al., 2011, with the following composition per liter as follows: 0.7 g KH2PO4, 0.3 g K2HPO4, 0.3 g MgSO4.7H2O, 25 mg CaCl.2H2O, 25 mg NaCl, 3 mg FeSO4.7H2O, 0.01 mg vitamin B1, and 1 ml A5 solution. Inoculum was prepared in 500 mL Erlenmeyer flasks having 100 mL of the above mentioned modified BG 11 medium, along with the carbon source at 30 g/L concentration and yeast extract at 4 g/L concentration respectively. Batch Fermentations •Experiments conducted in triplicates •All experiments were conducted aseptically with pure cultures •The medium was prepared as mentioned above and 100 ml of each medium containing 30 g carbon source/l and 4 g/L yeast extract was added • pH of each experimental unit was initially adjusted to 6.8 using 1M H2SO4 and 1 M KOH •The flasks were then autoclaved at 121OC for 15 minutes •The flasks were then cooled and inoculated with the inoculation flasks. 10% v/v of inoculum was used •Cultures were then incubated in shakers maintained at 160 rpm and 28OC Different treatments involving varying proportions of glycerol and xylose References: 24 g xylose/l + 6 g Concentration (g/l, Specific growth Treatment 30 g xylose/l Xylose concentration Glycerol concentration g/l g/l 1 30 0 2 24 6 3 18 12 4 12 18 5 6 24 6 0 30 Treatment 2 Fatty acid profiles for one of the treatments Dry weight studies (A) 30 g xylose/L (B) 24 g xylose/L and 6 g glycerol/L (C) 18 g xylose/L and 12 g glycerol/L (D) 12 g xylose/L and 18 g glycerol/L (E) 6 g xylose/L and 24 g glycerol/L (F) 30 g glycerol/L Substrate Utilization Studies •In all treatments the final glycerol concentration was approximately 0 g glycerol/l and xylose concentration was 2.5 g xylose/l • Rapid decrease in concentration of both the carbon sources were between the 2nd and the 5th day • It is understood that an increase in xylose concentration decreased the rate of consumption of glycerol •The glycerol seemed to be getting consumed completely both in the presence and absence of xylose at the end of the 6th day in all cases • xylose in combinations with glycerol proves be a good alternative as it is consumed steadily over all 7 days of the fermentation cycle to give better biomass yields than the controls. •The exact reason for this pattern can be better understood from studies of the metabolic pathways of the algae growth cycle It can also be noted from all the treatments that xylose was consumed by Chlorella protothecoides for growth. pH studies •pH variation can also be related to the substrate consumption •pH decreased initially in the presence of both mixed substrates and single substrates and started to increase as the substrates after getting utilized by the algae • The treatment with 30g crude glycerol/L showed a rapid increase in pH once the glycerol was fully consumed as opposed to the other treatments. •This could be owing to the nature of the minor impurities present in the glycerol that act as a natural buffering system and provide a congenial environment for the algae to grow (Liu et al., 2008) •In the treatment with 30 g xylose/L, the increase in pH after consumption of most of the xylose was the least Sheehan, J., Dunahay, T., Benemann, J., Roessler, P. 1998. A look back at the U.S. Department of Energy’s aquatic species program: biodiesel from algae. National Renewable Energy Laboratory, NREL/TP-580-24190, USA. B. J. Krohn, C. V. McNeff, B. Yan and D. Nowlan, Bioresour. Technol., 2011, 102, 94. Heredia-Arroyo T, Wei W, Hu B (2010) Oil accumulation via heterotrophic/mixotrophic Chlorella protothecoides. Appl Biochem Biotechnol 162:1978–1995 Dong M, Walker TH (2008) Addition of polyunsaturated fatty acids to canola oil by fungal conversion. Enzym Microb Technol 42:514–520 Mu,Y, H. Teng, D. Zhang, W. Wang, Z. Xiu. 2006. Microbial production of 1,3-propanediol by Klebsiella pneumoniae using crude glycerol from biodiesel preparations. Biotechnology Letters 28: 1755-1759 Heredia-Arroyo T, Wei W, Hu B (2010) Oil accumulation via heterotrophic/mixotrophic Chlorella protothecoides. Appl Biochem Biotechnol 162:1978–1995 Dong M, Walker TH (2008) Addition of polyunsaturated fatty acids to canola oil by fungal conversion. Enzym Microb Technol 42:514–520 Miao X, Wu Q (2006) Biodiesel production from heterotrophic microalgal oil. Bioresour Technol 97:841–846 Xu H, Miao X, Wu Q (2006) High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J Biotechnol 126:499–507 Thompson JC, He BB (2006) Characterization of crude glycerol from biodiesel production from multiple feedstocks. Appl Eng Agric 22:261–265 Chen YH, TH Walker, 2011, Biomass and lipid production of heterotrophic microalgae Chlorella protothecoides by using biodiesel derived crude glycerol, Biotechnol Letters, 33(10):19731983 •Cell dry weight was measured on a daily basis •A lag phase, growth or exponential phase, a stationary phase and death phase patterns where in existence •Treatment 3 had the highest biomass growth of 15.27 g biomass/l •Presence of xylose as a carbon substrate increased the dry biomass • At the end of the 7th day the controls of glycerol and xylose used as sole carbon sources yielded 12.41 g biomass/l and 12.04 g biomass/L respectively •Treatment 3 which had 18 g xylose/L and 12 g glycerol/L yielded the highest biomass of 15.27 g biomass/L. Treatment 2 which had 24g xylose/L and 6 g glycerol/L yielded 12.69 g biomass/L, treatment 4 having 12 g xylose/L and 18g glycerol/L yielded 13.33 g biomass/L and treatment 5 with 6 g xylose/L and 24 g glycerol/L yielded 13.82 g biomass/L • From the 7th day data it is evident that the biomass yield of Chlorella protothecoides was higher when mixed carbon substrates of xylose and glycerol were used as compared to either of the single substrates. Lipid content • Measured lipid contents for treatments 1 through 6 are tabulated in the table above •A decrease in xylose concentration produced higher lipids but its absence produced lesser lipids •This indicated that xylose is required but in lesser amounts. •Xylose also contributed to the biomass content and hence if higher biomass and lipids were required then 18 g xylose/l and 12 g glycerol/l combinations yielded higher biomass as well as lipids. Just going by lipid content 6 g xylose/l and 24 g glycerol/l yielded the highest amount of lipids when compared to all the treatments •The extracted lipids were profiled to observe the different types of fatty acids present in them •Profiling yielded stearic acid, oleic acid, myristic acid, linoleic acid, palmitic acid and lauric acid •All of these fatty acids are suitable for biodiesel production. Conclusion •Chlorella protothecoides was able utilize xylose •Effective utilization of xylose was when another carbon (glycerol) source was used in combination •Production of lipids and the cell dry weight was higher in the presence of both xylose and glycerol as carbon sources present together at a concentration of 30g/L •Extracted lipids were profiled •Further experimentation needs to be done at fed-batch mode for more control on pH , aeration and periodic substrate feeding for a whole rounded study of the algae growth •The lipids should be quantified to find better uses for them in biodiesel production •Other ASTM standard tests for biodiesel feedstock quality should also be performed on these lipids.