Part 1 - University of Toronto

advertisement

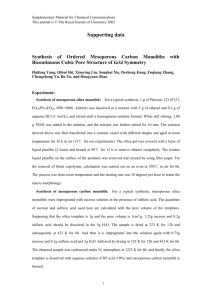

CHEM 1270H: TOPICS IN INORGANIC CHEMISTRY MESOCHEMISTRY SYNTHESIS IN “INTERMEDIATE” DIMENSIONS Geoffrey A. Ozin Materials Chemistry Research Group University of Toronto Tel: 416 978 2082, Fax: 416 971 2011 E-mail: gozin@chem.utoronto.ca Group web-page: www.chem.toronto.edu/staff/GAO/group.html MESOCHEMISTRY SYNTHESIS IN “INTERMEDIATE” DIMENSIONS • Purpose of the four lectures • Introduce key physicochemical design principles that underpin the template directed synthesis of inorganic mesoporous materials • Focus on synthetic control of structure, composition and form • Appreciate how the properties of materials fashioned at this intermediate length scale can be orchestrated to create a purposeful function directed to a specific field of use. Angew Chem 2006, 45, 3216 ZEOLITES CRYSTALLINE MICROPOROUS ALUMINOSILICATES WITH PORES AND CHANNELS IN SIZE RANGE 0.3-1NM ESCAPE FROM THE 1NM ZEOLITE PRISON ISI Citations 6386 ESCAPE FROM 10 Å PRISON • Discovery by Mobil researchers that an assembly of surfactant molecules could function as a supramolecular template for organizing and polymerizing silicates • Produced the first fully characterized examples of periodic hexagonal and cubic forms of mesoporous silica with pore diameters 2-10 nm • Integration of surfactant and sol-gel chemistry SOL-GEL CHEMISTRY Air drying SC CO2 drying SOL-GEL CHEMISTRY Air drying SOL-GEL CHEMISTRY Base catalyzed hydrolytic poly-condensation of silicon alkoxides to silica SOL-GEL CHEMISTRY Acid catalyzed hydrolytic poly-condensation of silicon alkoxides to silica • HYDROLYSIS • (RO)3SiOR + H3O+ (RO)3SiORH+ + H2O • 2H2O + (RO)3SiORH+ (RO)3SiOH + ROH + H3O+ • CONDENSATION • (HO)3SiOH + H3O+ (HO)3SiOH2+ + H2O • (HO)3SiOH + (HO)3SiOH2+ (HO)3SiOSi(OH)3 + H3O+ SOL-GEL CHEMISTRY Lyotropics Kraft T CO-ASSEMBLY SURFACTANT AND SOL-GEL CHEMISTRY MILESTONES IN MESOPOROUS MATERIALS • • • • • • • • • • Escape from the 1 nm prison (surfactant templated synthesis) Diagnostics (structure, property) Structure control (H, C, L, WH) Template removal (calcination, ion exchange, solvent extraction, photocalcination, ozonolysis, microwave, lizard fragmentation) Pore size control (surfactant, block copolymer, swelling additive) Templating mechanism (micelle, liquid crystal) Smart mesostructure (pore size expansion, metamorphic channels) Free-standing and supported film (mesoepitaxy, pore orientation) Topological defects (nucleation, growth, origin of curved pores and form) Morphogenesis of curved shapes (fiber, discoid, gyroid, spiral, sphere) MILESTONES IN MESOPOROUS MATERIALS • Nanomeso (nanoscale particles, nanocrystalline texture) • Biomimetics (biomineralization connection, hierarchy (nm-micron length scales), complexity, organic-inorganic nanocomposites or hybrids) • Panoscopic materials (global self-assembly over “all” scales, surfactants, block copolymers, opals) • Patterning (microcontact printing, micromolding in capillaries, microtransfer printing, ink jet printing, photolithography) • Smart guests (SC, M, OM, C, P) • Smart channels (terminal and bridging organofunctionality) • Beyond silica (metals, oxides, sulfides, phosphates, coordination, polymers) • Mesoreplication (carbons, metal oxides) • Function and utility (fuel cell, solar cell, battery, laser, low-k, controlled chemical and drug release, chemical/biosensor, electrochromic display, 1D Bragg photonic crystals, low refractive index optical cladding ) pH, pH, pH EFFECT ON SELF-ASSEMBLY MECHANISM Surfactant Catalyst Temperature pH Concentration Precursor Template removal Ageing conditions HYDROLYSIS, CONDENSATION, SELF-ASSEMBLY ESCAPE FROM 10 Å PRISON 100 110 200 210 HEXAGONAL MESOPOROUS SILICA Small angle X-ray diffraction hexagonal Nitrogen gas adsorption isotherms Mesoporous 2 -50 nm Macroporous > 50 nm cubic Microporous < 2 nm lamellar IUPAC CONVENTION FOR PORE SIZES CUBIC BICONTINUOUS MESOPOROUS SILICA Equipotential minimal energy surface Cubooctahedral morphology TEM image cubic mesoporous structure Mesocrystalline glass – crystalline mesoporosity - periodic arrangement of mesopores – glassy walls - long range order at mesoscale – short range order at microscale WHAT CAN WE DO WITH PMS MATERIALS? HOST-GUEST INCLUSION WITH LARGE GUESTS !!! ORGANICALLY FUNCTIONALIZED PMS - GRAFTING CLEVER USE OF GRAFTING CONTROLLED RELEASE OF ACTIVE COMPOUNDS NANO-PMS SMART DRUG DELIVERY AFM 2007 ORGANICALLY FUNCTIONALIZED PMS - COCONDENSATION PHOTOCHEMICAL SWITCH PORE SIZE CONTROL Synthesis of films bearing photosensitive azobenzene units: 4-(3-triethoxysilylpropylureido) azobenzene by the coupling of triethoxysilylpropylisocyanate with 4phenylazoaniline used as organosilane precursor in co-condensation reaction HEAVY METAL SPONGE Periodic mesoporous silica with channel walls functionalized with terminally bound alkanethiol groups that chelate and sequester toxic heavy metals. PERIODIC MESOPOROUSN ORGANOSILICAS PMOs ZOO OF PMO PRECURSORS Acc. Chem. Res. 2005, 38, 305-312. MATERIALS CHEMISTRY SOLUTION TO THE LOW k CHALLENGE Periodic mesoporous organosilicates PMOs with organic cross-links!!! Hatton, B.D., Landskron, K., Hunks, W.J., Bennett, M.R., Shukaris, D., Perovic, D.D., Ozin, G.A., New Materials Chemistry Approaches for Low Dielectric Constant Materials as Interlayer Dielectrics, Materials Today 2006, 9, 22. METAMORPHIC CHANNEL WALLS – PMO BRIDGE TERMINAL EXCHANGE PMO WITH ORDERED BRIDGING AROMATIC GROUPS IN THE CHANNEL WALLS MOLECULAR MODEL OF THE ORDERING OF BRIDGING BENZENE GROUPS IN THE CHANNEL WALL OF BENZENE PMO MOLECULAR MODEL OF THE ORDERING OF BRIDGING THIOPHENE GROUPS IN THE CHANNEL WALL OF THIOPHENE PMO BIFUNCTIONAL PMOs The Idea – PMO to MIPMO IMPRINT IMPRINT IMPRINT the idea imprint molecule imprint removal collaboration Jean-Christophe Leroux (CRC in Drug Delivery) Nature Nanotechnology. 2007, 2, 679-684. MIPMOs Schematic of the synthesis of molecular imprinted periodic mesoporous organosilica MIPMO materials Drug-PMOs commercially available drugs ↳silsesquioxane PMO precursors ↳assemble MIPMO structures ↳remove the drug imprints ↳detoxification calcium channel blockers Diltiazem Verapamil Drug Silsesquioxanes MESOPOROUS MATERIALS GRAND CHALLENGES – UTILITY • • • • • • • • • • • • • • • • Large (bio)molecule catalysis Polymerization nanoreactor Membrane separation Chromatography stationary phase Fuel cell anode Lithium battery electrolytes Electrochromic display Solar cell photo-cathode (Bio)chemical sensor Drug storage and release vehicle Heavy metal sponge Low dielectric constant film Low refractive index optical cladding Lithographic masks Nanofluidic ion channels Nanocomposites