File

advertisement

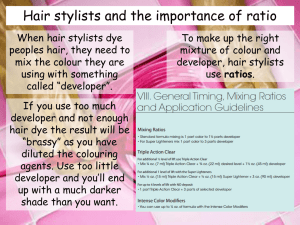

Radiographic processing Principles Introduction ►A latent image is formed in the film emulsion when exposed to different intensities of radiation passed through an object. ► Chemical processing of the film is necessary to make the latent image visible and permanent ► Film processing involves a number of complex chemical reactions whose activity and efficiency are influenced by various factors such as; Temperature Acidity or alkalinity (pH) of the chemicals used Processing cycle Dev. Rinse Fix Wash Dryer Processing stages Manual processing Automatic processing ► Development ► Development ► Rinsing ► Fixing ► Fixing ► Washing ► Washing ► Drying ► Drying Development ► Primary purpose is to convert into visible form the invisible latent image ► The silver halide grains affected by exposure are reduced to metallic silver ► Silver halide grains unaffected by exposure remains largely unchanged Chemical action of developer ► The emulsion becomes wet ► Chemicals penetrate in to the emulsion ► A process of chemical reduction takes place ► Developer donates electrons to the silver ions in the exposed silver bromide grains ► Silver ions by obtaining electrons converted into metallic silver (The mode of action is not fully known but explained as follows) Result of exposure on silver halide Unexposed AgBr grain Br Br Br - Ag+ - Exposed AgBr grain Br - Br - Ag+ Ag+ Br Ag+ Ag+ Ag+ Ag+ - Br Br - Br X ray photon Br - - Ag+ - - Ag+ Ag Ag Ag e Br Br Br Sensitivity Spec Sensitivity specs are deliberately formed during film emulsion production When exposed to radiation The bromine ion release electrons which lodge in the sensitivity area resulting attracting and neutralizing silver ions Mode of action of Developer Unexposed AgBr grain Br Br Br - Ag+ - Exposed AgBr grain Br - Br - Ag+ Ag+ Ag+ Ag+ + Ag+ Ag Br Br Br Br - Br - - Ag+ - - Ag+ Ag Ag Ag Br e Br Br Sensitivity Spec e Ag Br Mode of action ► AgBr grains are surrounded by a negative barrier of Br ions ► The charge barriers protect the silver ions from attack by electrons ► Exposed AgBr grains possess a weakness in the charge barrier caused by the presence of neutral silver atoms at the sensitivity specs (development centre) ► The development centre enables electrons from the developer to penetrate grain and reduce all its silver into metallic silver Result of over development ► If a film spends too long a time in the developer, or if the develop is hyperactive the charge barrier around unexposed grains may be unable to prevent electron penetration, and unexposed grains will be reduced to metallic silver ► Chemical fogging is the result Effects of the by-products of development ► With continuous use, the developer becomes depleted of electrons and it is said to be oxidized and reduced in activity ► The remaining negative Br ions react with positive hydrogen ions in the solution to form hydrobromic acid. H ► This causes the p to fall and reduces the developer activity ► The atmospheric oxygen also cause developer oxidation and reduce activity Constitution of developer solution ► The developer in automatic processing and manual processing are different in several aspects ► In automatic processing the solution added to the working developer in the tank is called developer replenisher ► When the developer tank is emptied and fresh solution is added the activity of the replenisher is modified by adding a chemical called the starter solution Developer replenisher + Starter = Working developer Constituents of developer replenisher solution ► Solvent ► Developing agent ► Accelerator ► Buffers ► Restrainers ► Preservative ► Hardener ► Sequestering agents Solvent – water Functions ► Acts as the carrying medium in which the developer constituents are dissolved. ► Provides a means of controlling the developer activity by diluting its effects. ► Has a softening effect on film emulsion to allow the chemicals to penetrate into the emulsion and reach AgBr grains ► (The water should be clean enough not to have any chemical reaction with the developer constituents ► It should not contain mud & dirt or particles which may cause damage to the delicate film emulsion) Developing agents ► Are reducing agents which supply electrons ► Should exhibit the following properties Must be selective and distinguish between exposed and unexposed grains Sufficiently high activity As resistant as possible to the presence of bromine ions in the solution ► No Single reducing agent which satisfies all of these requirements ► Therefore combinations are used ► Metol & Hydroquinone (MQ) were use in early manual developers ► Phenidone & Hydroquinone (PQ) are used in modern automatic processing Phenidone = 1-pheyl-3-pyrazolidone ► Quick acting ► Selectivity low ► Mildly sensitive to bromine ion in concentration ► Produces low contrast characteristics Hydroquinone ► Requires a strongly alkaline medium in which to act ► More selective than phenidone ► Slow to start the development action ► But once started acts rapidly on exposed AgBr grains ► Does not affect lightly exposed or unexposed grains ► Produces high contrast characteristics Advantages of PQ developer ► When phenidone and hydroquinone are together in one developer their characteristics complement each other ► Therefore PQ developers have the following advantages over the other developers ► Tolerance of increase in bromine ion concentration ► High selectivity and low chemical fog ► Adequate activity even in low concentration ► Available in liquid concentration form ► Fast acting permitting complete development in 20-30 seconds ► Adequate contrast characteristics ► Super-additive effect (the reducing effect of combination is much greater than the sum of the effects they produce when used separately) Super-additive effect Optical density The shape of the characteristic curve is controlled by the two developing agents Combine effect Phenidone only Exposure Hydroquinone only Accelerators ► PQ developers need an alkaline medium to operate ► It is established by adding a strong alkali ► Usually Potassium carbonate or Potassium hydroxide is used ► The alkali is known as accelerator since its function is to accelerate the developing process PH and development pH of the developer has a marked effect on its activity and on image contrast: ► The Low pH – low activity and development sluggish High pH – high activity and chemical fog range of pH values for different developers will vary from 9.8 to 11.4 H ► However for a particular developer the p should not vary. ► The Buffers ►A buffer is a chemical compound which has the effect of maintaining the pH of a solution within close limits ► Potassium sulphite used as the preservative and the potassium carbonate used as accelerator provides an adequate buffering action Restrainers ► Modifies the behaviour of developing agents so that they become more selective ► That is to reduce the tendency to convert unexposed silver halide grains to metallic silver and therefore to prevent chemical fogging ► KBr-The developer by product will act as a restrainer ► In PQ developer benzotriazole is used as a restrainer and an antifoggant. Preservatives ► To check oxidation of developing agents by the action of atmospheric oxygen ► Additionally it permits more efficient regeneration of Phenidone by hydroquinone ► Potassium sulphite is commonly used Hardeners ► To prevent excessive swelling of the emulsion by the absorption of water which is pronounced in the alkaline developer ► Powerful hardeners like glutaraldehyde may employed – they are more effective in alkaline developer ► But manufacturers use alternatives because of its undesirable allergenic effects ► Manual processing does not need hardeners Sequestering agents ► These are chemicals which prevent precipitation of insoluble mineral salts which tends to occur in hard water ► They act by combining with the minerals to form soluble compounds which do not react with the developer chemicals ► Compounds based on EDTA are commonly used Other constituents ► Bactericides ► Fungicides Starter solution ► The starter solution is added to the fresh solution in the developer tank at the start ► To reduce the initial activity of the developer to the safe working level by bringing down the pH to the correct value ► It is an acidic restrainer which provides KBr until the development process produce its self restraining effect ► Developer replenisher + starter = working developer ► Manual processing does not use starter solution Efficiency of development & Factors affecting development ► How is the efficiency of development measured? Or assessed? Assessing the optical density Assessing the contrast ► Factors influence the quantity and quality of development are Constitution of the developer Temperature of the developer Development time How Constitution of the developer affect development? The activity of the developer depends on Type of developer Concentration pH Concentration of restrainer & anti-foggant The developer activity reduces with use because, The concentration of developing agent and pH drops, while the concentration of restrainer increases ► Therefore the developer has to be replenished continuously if the activity is to be maintained. ► The rate of replenishment depends on The area of film processed Type of emulsion Type of image Aerial oxidation ► Not only the activity but the volume of developer also is reduced with use because of The developer carry over by the films Evaporation ► The replenishment compensates for this too How does developer temperature affect development? ► The developer activity increases with temperature ► The temperature has to be controlled and maintained if development is to be standardized Methods used – temperature & cycle times ► High temperature development ; 38 – 42 0 C , 90S ► Low temperature development : 20 – 30 0 C, 7m 90s ► Medium temperature development ; 37 – 33 0 C, 90s-160s Effect of increase of temperature ►A slightly increased temperature (0.5 0C) without compensating reduction of development time results in: Increased image density for the same exposure Slightly increased chemical fog Increased image contrast ►A more severe rise in temperature (several degrees) initially leads to Gross increase in density Unacceptably increase in chemical fog Reduction in contrast Effect of increase of temperature Effect of decrease of temperature ►A slightly lowered temperature will result in: Decreased image density for the same exposure Slightly reduced chemical fog Reduced image contrast ►A more severe fall in temperature will result in: Gross overall reduction in density Loss of contrast and reduced D-max Effect of decrease of temperature Developer temperature in manual processing ► Manufacturers of manual processing recommend a temperature of 20 0 C for optimum result. But they provide acceptable results two or three degrees high or low provided the developing time is adjusted accordingly Development time ► This is the time the film is kept in the developer ► In automatic processing it may be defined as the time interval which elapses between the entry of a specified part of a film (e.g. leading edge) into the developing solution and the exit from the developing solution of the same part of the film. ► It varies with the full cycle time of the processor 7 m -------- 130 s 3 ½ m ------- 68 s 110 s --------- 30 s 90 s ---------- 26 s ► Development time is determined by: Developer concentration Developer temperature Film type Agitation of developer solution ► Agitation of solution in automatic processing is achieved by Film motion Rotation of rollers Circulation of developer Summary ► Development is the most important part of processing ► The quality of the recorded image greatly depend on development ► To maintain standard development following has to be maintained as constant as possible Developer concentration by constant replenishment Constant temperature Constant time