Textiles in Transportation

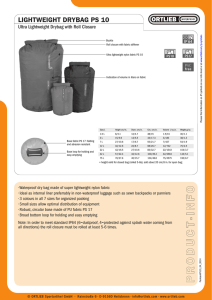

advertisement

Textiles in Transportation (MOBILTECH) presentation by NITRA Textiles in Transportation Market Size – It is about 23% of the total technical textiles market. However, in India its share is 7 % in technical textiles market. Auto makers sold 160,794 cars in August compared with 120,681 in the same month a year earlier, the Society of Indian Automobile Manufacturers (SIAM) announced in New Delhi today (Sept. 9, 2010). Domestic Market (2010-12) Rs. Crores Nylon tyre cord Seat belt webbing Air bag Car body covers Seat covers fabric/Upholstery Automotive interior carpets Headliners Insulation felts Sunvisors/Sunblinds Helmets Airlines disposable Webbing for aircrafts Aircraft Upholstery TT usage in railway TOTAL 2,425 22 35 17 868 290 59 494 154 759 5 5 1 2 5,145 MOBILTECH Land – Air/Space - Water • upholstery, car interior, carpets • tires, car elements, filters, • Heat, cable & sound insulation, • safety systems - airbags, seat belts • Protective covers for land crafts, boats, aircrafts • sailcloth, inflatable boats • Envelopes of balloons • Special equipment for military vehicles, Some of these textiles are visible while the others are concealed. Visible components: upholstery, carpets, seat belts, headliners etc. Concealed components – tyre cords, hoses, belts, airbags, air and fuel filters, noise and vibration dampening and body panel reinforcement in composites etc. FIBRE COMPOSITION IN AUTOMOTIVES APPLICATION AREAS FIBRES / PRODUCTS USED UPHOLSTERY Polyester, wool, nylon, acrylic Polyester, Nylon, HT * rayon, steel & aramid TYRE CORDS & FABRICS 0.5 4.2 COMPOSITE Glass, carbon, aramid, HT polyester & polyethylene RUBBER REIN- HT polyester, aramid FORCEMENT SEAT BELTS 5.5 0.2 2.6 HT polyester 3.5 15.4 AIRBAGS Nylon - 6,6, nylon - 4,6 CARPETS Nylon, polyester, polypropylene 0.4 cotton jute polyester polypropylene polyethylene polyamide viscose acrylic Percent share of Various Fibers in Automotives Source: David Rigby Associates Textiles in Passenger Cars GENERAL MOTORS TATA MOTORS DAEWOO PORSCHE TOYOTA SUZUKI MAHINDRA MOTORS VOLVO BMW HONDA FIAT FORCE MOTORS FORD HYUNDAI NISSAN MOTORS HINDUSTAN MOTORS Textile Materials used in Car Interiors TEXTILES USED IN CARS (Kg) ~20 kg Seat Covers Selection of fabric: Apart from the properties such as strength & comfort properties, the fabric should also have – – – – – – Resistance to Sun Light & UV (strength & color fastness) Abrasion Resistance Reduced Flammability Odour free Antistatic Soil resistance. Composition of seat cover It is a trilaminate consisting of face fabric, foam and scrim lining on the back. The specifications of the laminate depend on where the laminate is used: seat central panel or back or door panel... – PET face fabric – The foam is PE-PU or Polyether-PU; the latter being more hydrolysis resistant & is suitable for humid climates – Foam density – 26 to 45 Kg/m3, 2 to 22 mm thick, fire resistant. – The scrim fabric is warp knitted (nylon or Polyester), 30-90 g/m2 Q C & Testing (Seat Covers) Accelerated ageing: Light & UV Abrasion – Taber/Martindale/ Schopper Peel bond adhesion Color fastness – perspiration, crocking Flammability Strength – tensile/tear; seam strength Stretch and set Surface resistivity (antistatic) Stain resistivity Water wicking Resistance to micro organisms Fogging Odour Odor test It is measured to determine the odor propagation of the interior materials. • The specimen (either dry or wet) is placed in an air tight container for a specified time (2 to 24 hrs) and temperature (70 to 800C). Then the odour is evaluated by 3 to 6 persons and is graded in a scale of 1 to 5 or 1to10. Fogging Test • Tested for all interior and air ventilation systems for the presence of volatile organic constituents (VOC) • The specimen is placed in a closed glass container and heated at a specified temperature for a specified time. • The volatile compounds are collected on a glass plate or on a silver foil and the optical property of the glass plate or the increase in weight of the foil is measured to determine the fogging value. Accelerated ageing: Light & UV radiation-Seating fabric Standard Black Panel Temp (oC) RH (%) Wavelength( nm) Exposure hours Requirement on grey scale SES N 3295 89±3 50±5 300-400 185 (at 60 W/m2)/40M J Min 3 GME 60292 115±3 20±5 300-400 80±16 JASO M 403 83±3 50±5 300-400 100 /200 Min 3 HES D 6506/MS 30032 89±3 50±5 300-400 354 Min 3 GMW 3414 Cycle B 108±3 25±5 420 192 Min 3 Volks Wagon AG PV 1303 100±3 20±10 320 46 Mahindra/ Ford/SAE J 1885/ TSL 2100G Dark: 38±2 Light: 89±3 Dark: 95±5 Light: 50±5 340 250 Min 6 on blue wool Min 6 on blue wool Min 3 SES: Suzuki Engineering Standard, GME: General Motors Europe Engineering Standards, HES: Hyundai Engineering, Standard, SAE: Society of Automotive Engineers, TSL: Toyota Engineers Standards Accelerated ageing test Seat Belts Multilayer woven narrow fabrics – Maximum yarn packing for a given area to have maximum strength – Twill or Satin – HT PET yarns (320 ends of 1100 dtex or 260 ends 1670 dtex) – Softer & flexible along the length for comfort – Rigidity along the width to enable it to slide easily between buckles and retract smoothly into housings – Scuff resistant but not unpleasantly hard edges – Resistant to microorganisms Performance Standards (Seat Belts) – Restrain a passenger weighing 90 Kg involved in a collision at 50 Km/h into a fixed object – Minimum straight pull strength 30kN/50mm – Accelerated ageing – Finished product – resistance to fastening & unfastening 10,000 times How airbags work ? • The design is conceptually simple; a central "Airbag control unit" (ACU) monitors a number of related sensors within the vehicle: – – – – – – – accelerometers, impact sensors, side (door) pressure sensors, whell speed sensors, gyroscopes, brake pressure sensors and seat occupancy sensors. When the requisite 'threshold' has been reached or exceeded, the airbag control unit will trigger the ignition of a gas generator propellant to rapidly inflate a nylon fabric bag. As the vehicle occupant collides with and squeezes the bag, the gas escapes in a controlled manner through small vent holes. The airbag's volume and the size of the vents in the bag are tailored to each vehicle type, to spread out the deceleration of (and thus force experienced by) the occupant over time and over the occupant's body, compared to a seat belt alone. Working of Airbag Airbag (As a supplemental restraint) Frontal airbag The auto industry and research and regulatory communities have moved away from their initial view of the airbag as a seat belt replacement. The airbags are now designated as Supplemental Restraint System (SRS) or Supplemental Inflatable Restraints. Fabrics for Airbag • The fabric from which the air bag is made must withstand the force of the propellant chemicals. More importantly, the hot gases must not penetrate the fabric and burn the skin of the car occupant. • The earlier airbags were Neoprene coated Nylon 6,6 but lighter and thinner silicon coated versions soon followed. Latter, uncoated fabrics have appeared. • Airbags vary in size and configuration – driver side airbags: from 35 lit capacity upwards – for front passengers: form about 65 lit capacity upwards Fabrics for Airbag – – – – – – – – – – High bursting Strength Fire retardance Light weight, Compact-folding ability, Low cost. Reduced skin abrasion (softness) High tear propagation Resistance High anti slip properties to the seam Resistance against Ageing Defined Dimension stability Airbag (Fabric Quality Requirements) • HT multi filament nylon 6,6 – 210, 420 and 840 denier • High tear strength, high anti seam slippage, controlled air permeability (about 10L/m2/min) and be capable of being folded up into a confined space for over 10 years without deterioration. • Some tests require 75% property retention after 4000 hrs at 90-1200C, the equivalent of 10 yrs. UV exposure and also cold cracking resistance down to -400C. • Recently, Nylon 4,6 (Akzo) with melting point of 2850C has been introduced especially for airbags. The Future of Airbags Until recently, most of the strides made in auto safety were in front and rear impacts, even though 40 percent of all serious injuries from accidents are the result of side impacts, and 30 percent of all accidents are side-impact collisions. Many carmakers have responded to these statistics (and the resulting new standards) by beefing up doors, door frames and floor and roof sections. Cars that currently offer side airbags represent the new wave of occupant protection. Engineers say that designing effective side airbags is much more difficult than designing front airbags. This is because much of the energy from a front-impact collision is absorbed by the bumper, hood and engine, and it takes almost 30 to 40 milliseconds before it reaches the car's occupant. In a side impact, only a relatively thin door and a few inches separate the occupant from another vehicle. This means that door-mounted side airbags must begin deploying in a mere five or six milliseconds! Shaped Airbags Side Airbag There are essentially two types of side airbags commonly used today, the side torso airbag and the side curtain airbag. Knee airbag It is located beneath the steering wheel. Knee airbags are designed to reduce leg injury. Knee Airbag Side airbag inflated Side Torso Airbag Side-impact airbags or side torso airbags are a category of airbag usually located in the seat, and inflate between the seat occupant and the door. These airbags are designed to reduce the risk of injury to the pelvic and lower abdomen regions. Some vehicles are now being equipped with different types of designs, to help reduce injury and ejection from the vehicle in rollover crashes. Side tubular or curtain airbag The 1998 model BMW 7 were fitted with a tubular shaped head side airbags, the "Head Protection System (HPS)" as standard equipment. This is an industry's first in offering head protection in side impact collisions. This airbag also maintained inflation for up to seven seconds for rollover protection. However, this tubular shaped airbag design has been quickly replaced by an inflatable 'curtain' airbag for superior protection. Curtain airbag • Curtain airbags have been said to reduce brain injury or fatalities by up to 45% in a side impact with an SUV. These airbags come in various forms (e.g., tubular, curtain, door-mounted) depending on the needs of the application. Many recent have a long inflatable curtain airbag that protects all 3 rows of seats of high end vehicles. Rear curtain airbag In 2008, the Toyota iQ launched featuring the first production rear curtain shield airbag to protect the rear occupants' heads in the event of a rear end impact. Center airbag In 2009, Toyota developed the first production rear-seat center airbag designed to reduce the severity of secondary injuries to rear passengers in a side collision. Seat belt airbag In 2009, the S-class ESF safety concept car showcased seatbelt airbags. They will be included standard on the production Lexus LFA in late 2010, and the 2011 Ford Explorer will offer rear seatbelt airbags as an option. On motorcycles • Various types of airbags were tested on motorcycles by the UK Transport Research Laboratory in the mid 1970s. • In 2006 Honda introduced the first production motorcycle airbag safety system on its Gold Wing motorcycle. Honda claims that sensors in the front forks can detect a severe frontal collision and decide when to deploy the airbag, absorbing some of the forward energy of the rider and reducing the velocity at which the rider may be thrown from the motorcycle. • Airbag suits have also been developed for use by Motorcycle Grand Prix riders. They are connected to the motorcycle by a cable and deploy when the cable becomes detached from its mounting clip, inflating to protect the back. Headliners • It is multilayer construction: – Decorative face fabric – Soft touch PU foam – Chopped glass mat – Semi rigid PU foam (core material) – Chopped glass mat – Non-woven scrim fabric All layers are hot pressed with thermo plastic powder/film QUALITY REQUIREMENT FOR HEAD LINER (Resin Felt) UNIT REQUIRED VALUE Kg/m2 2.0 + 0.15 mm 2.9 + 0.5 Apparent Bulk Density g/cm3 0.38 – 0.67 Resin Contents (Min.) (%) 26 Flexural Strength (Min.) kg/cm2 60 Heat (Flexural Strength) (Min.) kg/cm2 50 Humidity (Flexural Strength) (Min.) kg/cm2 30 Flammability (Max.) Mm/Min 80 ITEM Mass per unit area Thickness QUALITY REQUIREMENT FOR SOUND ABSORBING MATERIALS (Silencer Pad) UNIT REQUIRED VALUE mm As per the end use g/cm3 0.38 – 0.67 Moisture Contents (Max.) (%) 15 Tensile Strength (Min.) Kpa 59 Glass Fogging Rate (Max.) (%) 10 Sound Absorbing Rate (ratio of absorption & reflection factor) (%) Depending on the component – Dash board, engine felts… Cm/Min 10 ITEM Thickness Density Flammability (Max.) Sound Absorption Test Acoustic Impedance is a measure of the propagation of sound waves in a medium. Sound insulation of a material is measured with an impedance tube wherein the test specimen is mounted at one end of rigid, smooth and airtight Impedance tube. Sound weaves are generated in the tube and the sound pressures are measured at locations near to the sample. The a constant related to the propagation of sound waves in an acoustic medium Nonwoven Applications • Bonnet: Bi-component yarn (nylon6 sheath with PET cover) to reinforce acoustic insulation • Air-filters: nonwoven with activated carbon and antibacterial chemicals to remove malodours • Carpets: less weight, low cost & recycling needle felt PP • Surfaces such as window seals, dash board components – PET & Nylon 66 flocked surfaces to eliminate rattles & squeaks as well as contributing to overall aesthetics. Automotive Carpet Structure 1. Decorative top layer of fiber Tufted BCF nylon or needle punched PET or PP back, latex coated with SBR or acrylic latex 2. Thermoplastic material for thermal moulding Polyethylene powder, meldable fibers, EVA or further thick layer of compounded SBR latex 3. Acoustic & vibration damping layers Heavy layer of shoddy fibers or PU foam CARPETS • Carpets are classified according to their application and location. TYPES APPLICATION LOCATION Type 1 Door trim, quarter trim Inner side surface of 2door car passenger compartment Type 2 Trunk trim Rear trunk inside Type 3 Floor Floor of passenger compartment Type 4 Cargo floor, High floor High floor surface of vans Type 5 Rear shelf Shelf behind rear seat QUALITY REQUIREMENT FOR CARPETS REQUIRED VALUE ITEM Mass per unit area Tensile Strength (MIN.) UNIT Type 1 g/m2 Type 3 Type 4 Type 5 Shall conform to drawing 20 20 (%) 3 3 3 3 3 Abrasion Resistance (MIN.) Grade 3 3 3 3 3 Immersion Shrinkage (Max.) (%) 1 1 1 1 1 Tear strength (MIN.) kg 5 5 7(Warp) 10(Weft) 10 5 Crease Resistance (%) 50 + 5 70 + 10 70 + 10 60 + 10 60 + 10 Fade Resistance (MIN.) Grade 4 4 4 4 4 Heat Resistance (MIN.) Grade 4 or above 4 or above 4 or above 4 or above 4 or above (%) 15 15 15 15 15 Odor (MIN.) Grade 4 4 4 4 .4 Color Fastness To Rubbing (MIN.) Grade 4 4 4 4 4 Color Fastness To Washing (MIN.) Grade 3 3 3 3 3 Mm/Min 80 80 80 80 80 Elongation normal state (MIN.) Fogging (Max.) Flammability (Max.) Kg/50mm Type 2 8(Warp), 35(Weft) 35 20 Indian Railways Technical Requirements for Fire Retardant Curtain & Upholstery • Resistance to Spread of Flame – – – – Size of the fabric damaged due to Fire Time of Continued Burning after Extinction of fire After Glowing Release of Burning Particles • Limiting Oxygen Index – Minimum Concentration of Oxygen required in the mixture with Nitrogen, which will Support Combustion of a Vertical Specimen • Deterioration of Visibility due to Smoke • Toxicity Index It determines the toxicity of the products of combustion in terms of small molecular species arising when a small sample of a material is completely burnt. Toxic Gases • • • • • • • Carbon dioxide (CO2) Carbon monoxide (CO) Formaldehyde (HCHO) Nitrogen oxides (NO + NO2) Hydrogen cyanide (HCN) Acrylonitrile (CH2CHCN) Phosgene (COCl2) • • • • • • • Sulphur dioxide (SO2) Hydrogen sulphide (H2S) Hydrogen chloride (HCl) Ammonia (NH3) Hydrogen fluoride (HF) Hydrogen bromide (HBr) Phenol (C6H5OH) Additional Requirements for FR Property Based on BS : 5852 • Cigarette • Butane Gas • Wooden crib BIS Tests • IS : 12467(Part 1) – Smouldering Cigarette • IS : 12467(part 2) - Match Flame Equivalent Requirements other than FR Property • • • • • • Mass of Fabric Breaking Strength Tearing Strength Colour Fastness to Dry and Wet Rubbing Colour Fastness to Day Light Dimensional Change Common FR Test Methods BS 5852 Part 1 "Match - test" (on finished / unfinished CO - fabric) Flame retardant against burning cigarettes Length : ± 68mm Diameter : ± 8mm Mass : 1g nominal igniting not less than 5mm not more than 8mm smouldering rate : 12 ± 3min / 50mm pass if :not more than 50mm damage within 60min : no flaming, smoke, heat, glowing Flame retardant for upholstery fabric Flame Length : 35mm (vertical); Ignition Time : 20s; Pass if : Flaming : max. 2min after removal of the burner, Smoke, heat, glowing : max. 15min after removal, Max. 100mm damage ↔↕ German Railway - "Upholstery - Test" Work Clothes EN 533 • Flame length : 40mm (vertical); Ignition time : 10s • Criteria : -after flame time; afterglow time; not charred area; formation hole; molten / flaming debris; borders reached Carpet ASTMD 5859-76 • Methenamine tablet • Steel plate : Æ 205mm • Pass if : charred area <= 25.4mm from inner edge : OK NF P 92-504 Rate of spread of flame test: Flame length : 35mm (vertical) Ignition : 30 times 5s with 3s intervals M1 if :- after flame time max. 1s; no flaming debris; burning speed max. 2mm/s NF P 92-503 Criteria : formation hole <20”; if yes ®NF P 90-504; M1 if : After flame time max.5 - damage afterglow max. 250mm; no molten / flaming debris Common FR Test Methods Cigarette Burning Test Match Test Carpet Testing Upholstery Test NITRA’s Test Facilities for Automotive Fabrics 1. Color Fastness to light Xenon Arc -For one sample -For two sample -For three sample GME 60292, SAE J 1885, TSL 3600G, TSL 0601, MS -300-35, AATCC 16 H JASO M 403-83, HES D 6601, JASO M 346, EDS-T-7415, GM 9538 P Xenon Tester (ATLAS) 2. Color definition/difference (XYZ & Lab value) (∆E) CCM Macbeth – 3100 Spectrophotometer Macbeth-3100 3. Abrasion resistance (Taber Type) Abrader wheel CS-10, H-22, & H-38 Up to 1000 cycles Up to 1500 cycles Up to 2000 cycles SAE J1530 – A, SES N3246, JASO 403, SAE J948, MS 300-32, SES N 3298, Taber Abrasion Tester (U.S.A.) 4. Flammability SAE J369, FMV SS 302, SES N 3245, HES D-6003, JASO M 313, GM 9070P, MS 3008 Flammability tester 5. Smell (Dry & Wet condition) TSL 3505G, TSM0505 G Hot Air Oven 6. Smell (40C- 95% RH X 400 HRS) TSL 3505G Humidity chamber 7. Odor Properties HES D6507, MS 300-32, FMLT 131-01 Hot Air Oven 8. Glass Fogging TSL 3608G, MS:300-54, EDS-T-7694-B, TSM 0503G U.V. Visible spectrophotometer NITRA’s Facilities 9. Color Fastness to Crocking & Rubbing FLTM BN 107-01, JASO M313, EDS-T-7643, MS 300-35 Motorised Crock Meter 10. Water inclusion 5SFTS-0303-O - 11. Color Fastness to Rubbing After Fade Resistance MS 300-35 & Fade Resistance Condition Xenon Tester And Crock Meter 12. Dimensional change by Moisturing/immersion shrinkage HES D 6506, JASO N 313-83, MS 30032, FLTN BN 105-01 Water Bath 13. Dimensional stability against humidity MS 300-32 Humidity Chamber 14. Dimensional Change By Heating HES D 6506, FLTM-BN-105-01 Hot Air Oven 15. Water Resistance/Repellency HES D 6506, MS 300-32 Spray Tester 16. Soil And Cleanability MS 300-32, FLTM BN 112-08 Launder-o-meter 17. Resistance To Bleeding AN 101-01 Perstirometer (James H. Heal) 18. Resistance To Perspiration AN 101-01 Perstirometer (James H. Heal) 19. Resistance To Heat (100ºC For 8 Hrs.) Hot Air Oven 20. Resistance To Humidity (40ºC-95% RH For 8 Hrs.) Humidity Chamber 21, Steaming In Auto-clave (100ºC For 1 Hrs.) Auto-clave