奈米碳球 – LED 篇

advertisement

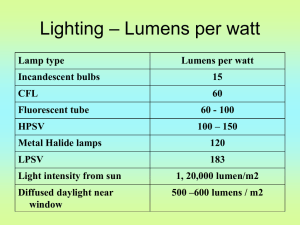

Carbon Nanocapsules The Application for Lighting Dr. Haley H. Lu (盧鴻智 博士) PhD from NTU Electro-Optical Engineering R&D Director of TCY-Tech Power Energy Limited The Emerging Trends of Lighting Evolution of Lighting Why LED ? Lower Energy Consumption consumes only 20~ 30% of incandescent lamps, 50% of halogen lamps. Longer Life Span 50000 ~ 100000 hours (10-12 years) Lower Light Decay A well managed LED light has less than 5% light decay after thousands of hours operation. Environmental Friendly No Filament – No Gas - No Mercury - No UV rays No Plumbum - No Hazardous Substance Why LED ? Eye – Protective LED lighting is free from strobe flash lighting that incandescent lamps and other lamps have. High Brightness A more vivid color of lighting, giving clearer images than low brightness lamps Wide Color Temperatures Warm white, Cool White, RGB, Ranging from 2700K – 7000K LED Key Factors Key Factors of LED Lighting Constant Current Driver Technology Power Factor Efficiency Stability in static current driving Light Decay Maintenance of brightness at a longer period Heat Dissipation Maintaining LED junction temperature at low to increase its lifespan Cost To be Economical in Mass Application Heat Dissipation Issue Impacts LED operation temperature rise with 2 major impacts: (1) Decrease luminance (LV) (2) Decrease LED Lifespan Luminance decrease example (For x-brand LED Chip): While Tj is 25℃(typical ambient temp.), the luminance (LV) is 100% Tj rises to 75℃ LV reduced to 93% Tj reaches to 115℃ LV reduces to 85% Tj reaches to 125℃ LV reduces to 83% Tj reaches to 150℃ LV only 80% LED Junction Temperature & Lifespan Relationship W Lower Tj 30,000 Tj v.s. LED life time (hrs) > 50,000 How to Disperse Excess Heat? Radiation/Convection; Passive/active energy transmission into immediate environment Conduction; External heat-sink: Copper “ladder” add-on frame Internal heat-sink: (Copper-INVAR-Copper) Thermally conductive substrate (non-metallic) Thermally conductive insulated metal substrate (IMS) Heat Dispersion by Heat Sink Passive Active Disadvantage of Active Heat Sink Expensive Boggy Disadvantage of Passive Heat Sink Boggy Depends on Thermal Convection Carbon Nanocapsules Solution Traditional Coating Materials Ceramic Boron Nitride, BN Silicon Carbide, SC Normally, reducing 3~5 ℃ Carbon Nanocapsules (CNCs) A CNCs is made up of concentric layers of polyhedral closed graphitic sheets, leaving a nanoscale cavity in its center. The size of the CNCs ranges from a few to several tens of nanometers, roughly the same as the diameters of multiwall carbon nanotubes. It can also be filled with metal, transitional metals or rare earth elements to exhibit unique photonic, magnetic and electrical properties and have molecular structures that can be readily functionalized for a variety of applications Properties Structure: Multi-Graphene Layers Size: d = 10~60 nm Aspect ratio: 1~2 Thermal Stability (O2): >600ºC Dispersion: Easy, after surface functionalized (40mg/ml) Disperse in: both organic and water based solvents/materials Radical Quenching Rate-(OH) (g/L)-1 s-1 : 1.16 × 108 Electric Conductivity(RT): 102 ~ 103 S/cm2 Thermal Conductivity(RT): ~1600 w/mk Radiation Heat Dissipation Technology for LED Increasing The Radiative Capability of Normal Heat Sink Convection Convection Heat Sink Heat Sink Conduction Conduction Heat Source Heat Source Without Coating With Coating Traditional vs CNCs Coating Aluminum Heat Sink Aluminum Thin Plate (40%~60% of the BOM cost) Boggy with CNCs Coating (30% of the BOM Cost) Thinner Or Different Design for Higher Power Same Design for Higher Power Increasing The Radiative Capability of Normal Heat Sink Up to 96% Heat Dissipation Improvement by CNCs Coating 14 W LED Module Font View Rear View With Coating Without Coating The Heat dispatching efficiency is the same Test Report Test Report Without Coating With Coating Comparison of Conventional LED and Spiral Bulbs Price Luminous Efficiency (lm/w) Max Luminance (lm) Spiral Bulbs LED Lamps 1 2~3 × 60~70 (Expensive) 70-80 (Power Consumption) >1500 <800 (Not Brightness Enough) Lifespan (hrs) 6,000 (Shorter Lifespan) 50,000 Does the LED Lamps have 50,000 Hours Lifespan Real ? 50,000 Hours Lifespan LED Chip Not LED Lamps LED Lamps = Chip + Driver + Heatsink + Parabolic Reflector + Lens + Package The 50,000 hours lifespan is estimated not REAL ! Do not be fooled! LED Lamps Lifespan Estimation Environmental Protection Agency & Department of Energy, USA LM-80 Test Data TM-21 Estimation Method Test Time : 6,000 ~10,000 hrs Sampling Interval : 1,000 hrs The real test is just about 1~1.5 years. Consumer always say: “ Why is the LED so easily broken? Light Ripple Non-high temperature Traditional LED LED Lamps Improvement Without Coating Luminous efficiency (lm/w) 15W LED Lamps Lamps Number with Same Luminance Lifespan (hrs) 65 975 lm With Coating 100 1500 lm 3 2 85,000 113,000 Product Excellence of TCY-Tech’s CNCs Film Hardness (1~10) 10:Diamond 9:Corundum 8:Topaz 7:Quartz 6:Orthoclase Film Thickness 95% 6-9H 100% 20µm Excellent CNCs Film Technology ! Thank You ! EMI Shielding Effect Temperature Measurement Phosphoric Glue Silicon Substrate Heat Dissipation Film LED T1 T2 T3 Radiative Heat Transmission Thermal radiation is generated when heat from the movement of charges in the material is converted to electromagnetic radiation. No medium is necessary for radiation to occur, for it is transferred by electromagnetic waves; radiation takes place even in and through a perfect vacuum。 Since the amount of emitted radiation increases with increasing temperature, a net transfer of energy from higher temperatures to lower temperatures results. Comparison