Stabilization of polymers

advertisement

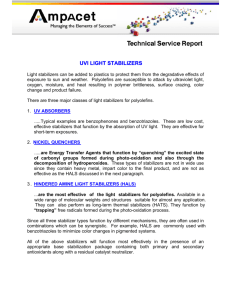

ADVANCED BIO-FRIENDLY POLYMERS Thermal, antioxidative and photochemical stabilization of polymers: low molecular weight versus macromolecular stabilizers György Kasza Industrial polymers Harmful effects in the production, processing and application of polymers: light oxygen Lead to photo-, thermal- and oxidative degradation of the products heat Mechanism of thermal oxidation of polymers 1) Chain initiation 3) Chain branching 2) Chain propagation 4) Chain termination Antioxidants: primary (chain-breaking) interfere with the chain propagation step secondary (preventive) destroy hydroperoxide groups Stabilization by chain-breaking antioxidants Two reaction mechanisms by which antioxidants interfere with chain-carrying radicals: Chain-breaking donor mechanism (CB-D) phenols, disubstituated phenols, secondary aromatic amines Chain-breaking acceptor mechanism (CB-A) quinone-type compounds stable free radicals: e.g. piperidinoxyl-compounds Chain-breaking donor mechanism (CB-D) The radical abstract a H atom from the inhibitor (AH) which is transformed into the radical (A) which can interact with another peroxy radical: The most widely used antioxidants are ortho-disubstituated phenols. Stabilization by secondary (preventive) antioxidants (1) Decompose hydroperoxides without intermediate formation of free radicals. Phospites reduce hydroperoxides to the corresponding alcohol and are transformed into phospates: can react with peroxy and alkoxy radicals: Stabilization by secondary (preventive) antioxidants (2) Decompose hydroperoxides without intermediate formation of free radicals. Organic sulfides transform two molecules of hydroperoxide into alcohols: Examples of industrial antioxidants OH O OH O NH HO O C18H37 CH3 O 2 NH NH NH NH CH3 H3C C18H37 S C18H37 S S OH HO P O O H N O O (CH2)8 O N H C9H19 3 Commercially used antioxidant ®IRGANOX 1010 (Ciba) Pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate) PHENOLIC PRIMARY ANTIOXIDANT FOR PROCESSING AND LONGTERM STABILIZATION of organic substrates such as plastics, synthetic fibers, elastomers, adhesives, waxes, oils and fats. Synthesis: HO OH OH OH + TRANSESTERIFICATION Base cat., HO O O Effect of catalyst residues and metal contamination In the presence of catalytic amounts of certain metal ions, hydroperoxides decompose already at room temperature by a redox mechanism into radical products: The most active catalysts: derivatives of those metals, which are easily oxidized or reduced by one-electron transfer and have different oxidation state: Fe, Co, Mn, Cu, V, Ti (transition metals) Much more efficient inhibition is achieved by using metal deactivators, together with the antioxidants. Effect of light stabilizers Small amounts of impurities or chromophores can be sufficient to induce photooxidative degradation even in the absence of appreciable UV absorption by a polymer. Types light stabilizers UV absorbers: absorption of harmful UV radiation and it dissipation that does not form heat. Need a thickness. Dihydroxybenzophenones and hydroxyphenyl benzotriazoles Quenchers of excited states: light stabilizers able to take over energy absorbed by the chromophores present in the plastic and to dispose of it efficiently to prevent degradation. Hydroperoxide decomposers: metal complexes of sulfur-containig compounds such as dialkyldithiocarbamates, dialkyldithiophosphates and thiobisphenolates. Effect of light stabilizer (2) Free radical scavengers: analogous to that used in prevention of thermal degradation some phenolic antioxidant can improve the light stability Mechanism: Hindered Amine Light Stabilizers (HALS) Free radical scavenger Does not absorb any light above 250 nm Mechanism („Denisov cycle”): under photooxidative conditions sterically hindered amines are converted to the corresponding nitroxyl radicals nitroxyl radicals combines with alkyl radicals and hydroxylamine ethers form in this reaction peroxy radicals can react very quickly with hydroxylamine ethers and regenerate nitroxy radicals FUNDAMENTAL PROBLEM The small-molecule additives (e. g. antioxidants, UV-stabilizers, plasticizers etc.) can easily migrate to the surface, thus increase their solubility and contaminate the environment. FOIL SOLUTION: MACROMOLECULAR STABILIZERS Macromolecular stabilizers Advantages – Very low migration to the surface – Long and predictable effect – Properties (eg. solubility, miscibility) can be easily modified by molecular weight and functionality Disadvantages – Further functionalization reactions, which are often expensive and time consuming Macromolecular additives in the market Hydrolysis stabilizer (Rachig GmbH) Light stabilizer (Ciba) Resistant to acidic environments (Chemtura) UV and long term heat stabilizer (Vanderbilt) THANK YOU FOR YOUR ATTENTION! Thermal, antioxidative and photochemical stabilization of polymers: low molecular weight versus macromolecular stabilizers György Kasza Department of Polymer Chemistry, Institute of Materials and Environmental Chemistry Research Centre for Natural Sciences, Hungarian Academy of Sciences DEGRADATION OF POLYMERS POLYFRIEND Educational Course September 5, 2013 Bratislava, Slovakia