simple steam distillation

advertisement

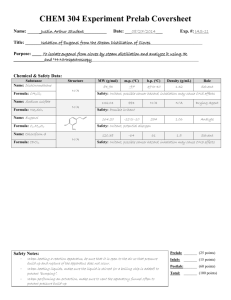

Kimia minyak atsiri TEKNIK PRODUKSI MINYAK ATSIRI PRODUCTION OF ESSENTIAL OILS Essential oils may be produced i. By steam - Simple steam distillation - Saturated steam distillation - Hydrodiffusion Ii Iii Iv By expression By solvent extraction By Enfleurage ENFLEURAGE These procedures take advantage of the liposolubility of the fragrant components of plants in fats. “Enfleurage” – the plant material is placed in contact with the surface of the fat. Extraction is achieved by - Cold diffusion into the fat - Digestion – carried out with heat, by immersing the plant in melted fat (also known as hot enfleurage). The final product is known as a floral pomade. • One of the oldest techniques • Advantages : Flowers continue to produce aroma compounds for several days after day have been picked. Ex: jasmine produces 4-5 times essential oils than is present at any time in the fresh flower. Disadvantage : very high labour cost involved Enfluerage Tehniques • Cold Enfluerage: • a single layer flowers is placed on a tray covered beforehand with a thin layer of grease, which absorbs the volatile compounds from the flowers. • The absorption take several days (ex 1-3 days), after which theflowers replaced with fresh ones until the grease is saturated. • The resulting product is called pomades and was either used directly in cosmetics, or wased wit alcohol. The resulting solution known as an extrait or absolute de pomade • Hot Enfluerage: • Flowers are placed in linen bag, which are then dipped in melted fat, vegetable oil or mineral oil heated to about 50-60oC. After maximum 12 hours the bags removes and replaced with fresh ones. SOLVENT EXTRACTION This methods gradually replaces te metods of enfleurage Garnier obtained a patent for novel type of extractior that became widely used first in France. Extraction is generally preceded by a process of: bruising the fresh, wilted or semi-desiccated organs, chopping herbaceous drugs, pounding roots & rhizomes or turning wood into chips or shavings. The procedure is conducted in specialized facilities e.g. Soxhlet-type extractor. SOLVENT EXTRACTION The solvent selection is influenced by technical & economical factors - Selectivity (being a good solvent for the specific constituents). - Stability (chemical inertness) - Boiling point should not be so high that the solvent can be completely eliminated; nor too low, to limit losses & control cost - Handling safety Solvents most used are aliphatic HC’s – petroleum ether, hexane, propane & liquid butane. Although benzene is a good solvent, its toxicity increasingly limits is use. SOLVENT EXTRACTION At the end of the procedure, the solvent contained in the plant material is recovered by steam injection or vacum evaporation. Main disadvantages of solvent extraction - Lack of selectivity, many lipophilic substances may end up in the concretes & render further purification necessary. - The toxicity of solvents leads to the restrictive regulations regarding their use - Residues in the final product. EXTRACTION BY SUPERCRITICAL GASSES Beyond its critical point, a fluid can have the density of a liquid & the viscosity of a gas therefore diffuses well through solids, resulting in a good solvent. CO2 is the main gas used Advantages of CO2 - It is a natural product - chemically inert, non-flammable - non-toxic - easy to completely eliminate - selective - readily available - Inexpensive EXTRACTION BY SUPERCRITICAL GASSES DISADVANTAGE: Technical constraints - High cost of initial investment ADVANTAGES: - obtain extracts which are very close in composition to the natural product. - It is possible to adjust the selectivity & viscosity, etc by fine tuning the temperature & pressure - All result in the increase of popularity of this type of method EXTRACTION BY SUPERCRITICAL GASSES USES Initially developed to decaffeinate coffees, prepare hops extracts or to remove nicotine from tobacco, the method is now used to - Prepare spice extracts (ginger, paprika, celery) - Specific flavours (black tea, oak wood smoke) - Plant oils - To produce specified types of a certain product, e.g. thujoneless wormwood oil. EXPRESSION (E.G.OF CITRUS EPICARPS) The rind is lacerated, and the contents of the ruptured secretory cavities are recovered. CLASSIC PROCESS: an abrasive action is applied on the surface of the fruit in a flow of water. The solid waste is eliminated, and the essential oil separated from the aqueous phase by centrifugation. OTHER machines break the cavities by depression, and collect the essential oil directly prevents the degradation linked to the action of water. EXPRESSION • Many component of essential oils from citrus fruits are delicate and suffer significantly from heat degradation when exposed to steam distillation • In cold expression, the fruit peel is compressed, lacerated to rupture the oil cells in the exocarp and release the essential oils. • 2 methods cold expression : • Spugma or sponge methods: fruits were halved , and juicy pulp was removed with a spoon-shaped knife. The peel was placed in warm water and pressing against a sponge with sufficient force. The sponge was periodically squeezed over a collecting vessel. • Scodella or spoon methods: used a funnel-shaped bowl, fruits turned and pressed. The mixture of essential oils released together with cell contents was collected in the bottom of funnel. EXPRESSION OF CITRUS EPICARPS Most facilities allow for the simultaneous or sequential recovery of the fruit juice and of the essential oil, by collecting the oil with a spray of water after the abrasion (scarification – puncture by pins) before or during the expression of the fruit juice. Enzymatic treatment of the residual water allows recycling, and markedly increases the final yield of essential oil. Citrus oils are also obtained directly from the fruit juices (by vacuum de-oiling) DISTILLATION a. SIMPLE STEAM DISTILLATION/ WATER DISTILLATION The principle is to boil and vaporize a suspension of aromatic plant material and water in a vat so that its vapours can be condensed and collected. The essential oils is separated by gravity. Plant material is immersed directly in a still filled with water. This is then brought to a boil. Heterogeneous vapours are condensed on a cold surface. Essential oil separates based on difference in density and immiscibility. In the 11th cemtury, Abu Sina added the frame to the vat, fixed above the level of water, on which the material to be distillated was placed. b. SATURATED STEAM Plant does not come into contact with the water steam is injected through the plant material placed on perforated trays. It is possible to operate under moderate pressure. Advantages: Limits the alteration of the constituents of the oil It shortens the duration of the treatment It conserves energy It can also be conducted on on-line in automated set ups. c. HYDRODIFFUSION Pulses of steam is sent through the plant material at very low pressure from (top to bottom). ADVANTAGE: Normally produces a product of high quality. Saves time and energy. iii. OTHER METHODS - Steam distillation by microwaves under vacuum. In this procedure, the plant is heated selectively by microwave radiation in a chamber inside which the pressure is reduced sequentially. - fresh plants require no added water. - ADVANTAGE: This method is fast, consumes little energy and yields a product which is most often of a higher quality than the traditional steam distillation product. Distillations: Steam Distillation 1. Steam distillation arises from an interesting curiosity of immiscible systems 2. The distillation of liquids that are fully miscible is governed by Raoult’s Law PT = NAP˚A +NBP˚B + NCP˚C + … (1) • • 3. The mixture will have its own unique boiling point The contribution of each component to the vapor phase is related to its partial vapor pressure and mole fraction In the distillation of immiscible liquids, the two act as two separate liquids A B Distillations: Steam Distillation 4. The total vapor pressure above an immiscible system is equal to the sum of the vapor pressures independent of their relative amounts PT = P˚A + P˚B + P˚C + … (2) 5. The mixture will boil at a temperature typically lower than either liquid 6. Consider a mixture of iodobenzene and water: At 98 IoC the value of each vapor pressure is: H H O 46 torr + 714 torr = 760 torr Mixture boils! Distillations: Steam Distillation 7. The mole fraction of each component (nA and nB) in the vapor phase is given by the ratio of its partial pressure over the total pressure: nA = P˚A/PT (3) and nB = P˚B/PT (4) 8. If the vapor is condensed, the resulting distillate has the same composition. The ratio of the mole fractions for A and B in the distillate is then given by Equation 5, which results from dividing equation 3 by equation 4: nA/nB = P˚A/P˚B (5) • Thus in the case of the steam distillation of iodobenzene and water, the vapor phase, iodobenzene would only have a mole fraction of 0.064 (46 torr/714 torr) • But because it has a larger molecular weight (204 vs. 18 grams per mole) about 0.7 grams of iodobenzene are collected for every gram of water • In the gas phase the two are fully miscible, but once the vapor condenses – the two are no longer miscible – and can be physically separated Distillations: Steam Distillation B. Uses/Apparatus • This method is typically used to extract the volatile components of plants for use in perfumery, flavors or aromatherapy products. • Steam distillation is used in the industries that produce these products as well as amateur set-ups like this one Isolation of Natural Products • This isolation of a “natural product” from its native matrix is one of the oldest examples of applied organic chemistry – medicines and herbal remedies prepared by early human civilizations are good examples of this • This field undergoing explosive growth as we attempt to find interesting molecules in nature that can be used for medicinal purposes as well as for flavorings, dyes and cosmetics from a natural rather than synthetic source • The American Chemical Society (ACS) publishes a Journal that covers recent developments in this highly interesting and important field • Papers start with the isolation of the animal or plant from it’s native environment followed by the various separation and identification techniques used to identify each component • Recently, the initial assays of the anti-microbial, anti-carcinogenic and toxicity behavior of each component are also reported When these isolations are for medicinal purposes, the field is known as Pharmacognosy "Pharmacognosy" derives from two Greek words, "pharmakon" or drug, and "gnosis" or knowledge. Like many contemporary fields of science, pharma-cognosy has undergone significant change in recent years and today represents a highly interdisciplinary science which is one of five major areas of pharmaceutical education. Its scope includes the study of the physical, chemical, biochemical and biological properties of drugs, drug substances, or potential drugs or drug substances of natural origin as well as the search for new drugs from natural sources. Research problems in pharmacognosy include studies in the areas of phytochemistry, microbial chemistry, biosynthesis, biotransformation, chemotaxonomy, and other biological and chemical sciences. TREATMENTS OF THE OILS Occasionally it is necessary to decolourize, neutralize or rectify the oils obtained. i. Steam jet under vacuum Allows for the elimination of smelly or irritating products, and to obtain a final product of desired “profile”. ii. Chromatrographic techniques This permits a good separation of the essential oil from non-volatile lipophilic compounds. iii. OTHER METHODS - Steam distillation by microwaves under vacuum. In this procedure, the plant is heated selectively by microwave radiation in a chamber inside which the pressure is reduced sequentially. - fresh plants require no added water. - ADVANTAGE: This method is fast, consumes little energy and yields a product which is most often of a higher quality than the traditional steam distillation product.