Technology for Clean Water

Sorbster™ Media for Water Treatment

Wastewater, leachates, ground water and ponds

. All rights reserved MAR Systems Inc.

1

Sorbster™ Media Properties

•

Removal of soluble heavy metals from water by chemisorption

•

Bonding at chemically enriched sites throughout enhanced alumina-based media

•

High adsorbent capacity: Up to 75% by weight

•

Ability to reach ultra low levels (ppb and ppt)

•

Effective across broad pH range: pH 3 to 10

•

Does not support bacterial growth

•

Multi-metal removal in single water pass

•

No ancillary waste stream

•

Low fouling potential

•

Low energy requirement

•

Passes TCLP for non-hazardous disposal option

. All rights reserved MAR Systems Inc.

2

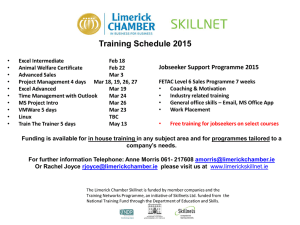

Sorbster™ Adsorbent Media Types

Sorbster (Sorbster

MM, Sorbster Hg,

Sorbster Se)

•Multi-metals removal

•Selenium Optimized

•Mercury Optimized

Sorbster F,

Sorbster Cu

•Fluoride

•Copper

Sorbster Si

•Silica

•Water flow is the only control parameter

•Establish water-to-media contact time

•Reacted chemistry provides adsorption sites for both

soluble cations and anions

•Aluminum, ammonia and iron sites

• rapid bonding of selenite and selenate anions

•Sulfur and oxide sites

•rapid bonding of cationic selenium, mercury, cations

Avoid surface active chemistries that can coat surface sites and sustained levels of free oxidants

. All rights reserved MAR Systems Inc.

3

Sorbster™ Selective Adsorption Capability

Contaminants Removed

Mercury

Arsenic

Selenite

Copper

Fluoride

Selenate

Cadmium

Thallium

Vanadium

Tin

Barium

Hexavalent

Chromium

Antimony

Cobalt

Silica

Lead

Zinc

Boron

Molybdenum

Nickel

Cyanide

Up to 99% removal

to achieve

Mercury <1.3ppt

Selenium < 1.0 ppb

Most Typical Water Ions Do Not Interact &

Pass Through Sorbster™ Media

Inlet to Sorbster™

(ppm)

Outlet of Sorbster™

(ppm)

Chloride up to 20,000

ppm

Chloride up to 20,000

ppm

Calcium up to 3500 ppm

Calcium up to 3500 ppm

Magnesium up to 6000

ppm

Magnesium up to 6000

ppm

Sulfate* up to 89,000

ppm

Sulfate* up to 89,000

ppm

Iron and Aluminum up to

10 ppm

Iron and Aluminum up to

10 ppm

This table shows client water results, these are not maximum

levels for the media

*Occasional sulfate removal to 30% maximum

. All rights reserved MAR Systems Inc.

4

Opportunities for Sorbster™ Use

Alternate for/

replacement of:

Hydroxide/sulfide/ carbonate/iron

precipitation

Chemical/polymeric precipitation

Pretreat:

Remove bulk of

contaminant before

another process

Ion exchange

R/O

Carbon adsorbents

Polish:

Remove low metals levels

to accomplish discharge

limits behind existing

processes

Membrane Bioreactors

Dilution

. All rights reserved MAR Systems Inc.

5

Sorbster™ Media Application

Contaminated

Water Stream

• Deployed in industry-standard vessels

• Pump and Treat Application

• Temporary application

• Leased/rented equipment

• Quick contacting time for smaller

equipment footprint & lower capital

cost

Flow

Through

Sorbster

Media

• Water flow rate is the only control

parameter

• Breakthrough determined by

monitoring effluent

• Lead-lag vessels for continuous

operation during change out

Clean

Water

. All rights reserved MAR Systems Inc.

6

Flow-Through and Passive Treatment Options

for Deployment of Sorbster™

. All rights reserved MAR Systems Inc.

7

Lab Evaluation of Client Waters – “Send Us Your

Water” Testing Service

5 to 10 gallon water samples

shipped to MAR

Packed bed of media in 1” by 36”

height columns

•

Hydraulic loading of 2 gpm/ft²,

up-flow

• Contact time determination

• Minimum of 15 bed volumes

treated

• Pretreatment testing

• SUYW report

. All rights reserved MAR Systems Inc.

8

Field Demonstration Units

•

MAR Field Demonstration Unit

–

•

Objectives:

–

–

•

Flow rates from 1 – 75 GPM

Contaminant removal on varying water

conditions

Optimize contact time

Typical Scope:

–

–

–

–

–

–

Demonstration test plan (treatment

objectives and analytical testing)

Installation & startup supervision

MAR technical team telephone

consultation

Scheduled site visits

Other scope options available

Final Report and Recommendations

. All rights reserved MAR Systems Inc.

9

Where Can Sorbster™ be Used?

• Applications of Sorbster™

– Flow-through vessels in lead-lag - pump and treat

– Temporary applications

– Soxx

– Sorbster fines for remediation cap & treat

– Wetlands barriers

– Intermittent flows – but keep Sorbster wet

. All rights reserved MAR Systems Inc.

10

Technology for Clean Water

For the removal of :

Mercury

Arsenic

Selenium

Copper

Fluoride

Cadmium

Thallium

Vanadium

Tin

Barium

Hexavalent Chromium

Antimony

Cobalt

Silica

Lead

Zinc

Boron

Molybdenum

Nickel

Cyanide

Rob Haney

West Coast Regional Sales Manager

Cell: 760-803-1813

rhaney@marsystemsinc.com

Missy Hayes

VP Business Development

440-505-0962 x: 100

mhayes@marsystemsinc.com

. All rights reserved MAR Systems Inc.

11