Developing catalytic screening in Chem. Dev.

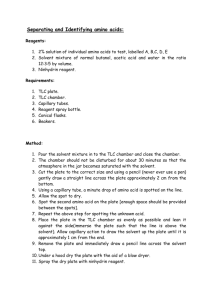

advertisement

Introducing Milligram Screening Reactions into the Kilogram World of Chemical Development Simon Yates, AstraZeneca. FreeSlate European User Meeting 24th September 2013 Our Journey so far… What is Chemical Development? • We produce a scalable process, not just a compound • From a few grams in the lab to multi-kilo plant campaigns • Emphasis on SELECT criteria • Safety • Economics • Legal • Environment • Control • Throughput Scavenging Challenge? Transition Metals are toxic! In number of metal catalysed reactions in Med Chem The time to develop process for early compounds Conventional work up takes time to develop Development time by using scavengers Of scavengers and carbons to choose from Time, effort and missed opportunity by automated screening Reproducibility by screening under inert conditions What are scavengers? But what kit? Integrity 10 • 10 reactions at a time • Minimum volume ~2mL But what kit? • Inerted Glovebox • 20mL reaction tubes • 100mg reactions • 24 wells • Very manual • Lots of programming MT Flexiweigh 2x MT Mini Mapper Wanted to…. In number of reactions we could run (up from 24) Reaction scale Manual intervention, to make this as routine as possible Ease of programming and data analysis ‘Future proof’ our investment Purchased a Symyx CM2 Solid Dispensing 10G needle (5mL syringe) 9 heat-stir bays Bespoke filter equipment - Symyx filter too small Vial gripper 16G to 20G needle (with N2 pressure) - 1mL & 500uL syringes attached to 10 off deck solvents Scavenging Workflow 96 x 1mL vials ~40 different scavengers Stock of reaction solution Seal, heat, stir 16 hours Scavenging Workflow Backing Solvent Air Gap Overshoot ICP sample HPLC sample RAS Centrifuge for 5 min ICP = Inductively Coupled Plasma Scavenging today • We have run 20+ screens and saved projects time and money • Numerous examples of where scavengers used in all scales of manufacture • Pd is most common metal scavenged, now have a generic plate of 22 scavengers. • Improvements in whole workflow reduced time from 5 working days to 2 days. Cross Coupling R1-M R2-X R1-R2 Background Original plan was to run X-Coupling Timing forced by closure of our existing facility In number of reactions we could run cover more experimental space, quicker. Reaction scale Apply our previous learning What we developed Pre-screening ~10 reactions Discovery 96-well 96-well plate plate screening screening Development Optimisation of Optimisation of continuous continuous parameters parameters (24-plate) DoE (24-plate) Life Cycle Management Generic Reaction Plates • Developed ‘Generic plates’ for 5 different reaction types • Based on literature and in house expertise 18 Generic plate formation Stock solutions of - Ligands - Metals - Internal std 19 Manual Pipette -or Automated dispensing Evaporate off carrier solvent and store Running a project… Define: Bases and Solvents Add in solid(s) Reactants Add in reaction solvent Running a project… Quickly add in Aq. Base ‘Start of reaction’ Seal up Heat and Stir 2 x Manual Sample Prep ~2hrs and 20hrs Future improvements Reactions run on 200-400uL scale at 10C below bp Solvent loss / corrosion of sealing material Fully closed plate Can’t sample by CM2 1st sample will always be manual 2nd sample could be automated – middle of night. Need a pierceable, but re-sealable, membrane Any ideas welcome!! 24 well - DoE type Expanding on 96 well hit(s) A B Discrete variables Continuous variables Material consumption Profile reactions Statistical Analysis 24 well – DoE type Catalyst Plate 24 x 4mL vials Weigh in Ligands Metal Add reaction solvent Cap, heat and stir, 60min. Reaction Plate 24 x 4mL vials Weigh in Reactants, Bases Internal Standard Add reaction solvent/liquid reagents 24 well – DoE type Transfer from Catalyst plate to reaction plate Reaction Plate Heat and Stir Automatically sample 4 times over 16 hours Run LC-Mass Spec on samples Future improvements 1 Temperature (plate) per run Lose a key factor Multiple Plates / run sampled into 1 HPLC plate Future improvements Sampling always run at the end, not good for fast reactions Allow sampling as part of ‘dispense’ And/or move vials to heat zones to ‘start’ reactions (Josh Denette and Kristin Price at Pfizer) Data Handling MDB RAS 29 Asymmetric Hydrogenation Successfully built capability in Sodertalje, Sweden site end of 2012 Opportunity to purchase new equipment CM3 (in glovebox) and SPR Off deck hydrogenation – make use of CM3 during long reactions Knowledge of LEA / CM2 CM2 / CM3 used as 1 resource for X-Coupling and Asymm. Hydrog. Commissioning - NOW Conclusion We have come along way since 2007 Scavenger was the warm up act • Scavenging and X-Coupling saved millions of dollars already • Success led the way to keep Asymm. Hydrog. in house • Asymm. Hydrog. will have similar if not bigger impact Continue to develop workflows Keep control of the data 96 x 2 x 5 x 50 = 48K data points / year Conclusion User community carry on sharing and learning What’s good for me, could be good for you too. Acknowledgments AstraZeneca John Leonard, Gair Ford, Barney Squires Phil Hogan, Keith Mulholland, Andy Campbell Rachel Munday, Kevin Leslie Sarah Thompson, Andy Poulton Ex AstraZeneca Paul Murray and co. (catsci.com) Per Ryberg and co. (SP Technical Research Institute of Sweden) Symyx/FreeSlate Steve Yemm, Zack Hogan, Colin Masui, Anny Tangkilisan, Rob Rosen, Eric Carlson Peter Huefner, Grant Gavranovic, Justin Fisher, Jonathan Harris Peter Gravil, Jos De Keijzer, Rick Sidler, Tony Mani, Guillaume Magan, Ludovic Edvard Confidentiality Notice This file is private and may contain confidential and proprietary information. If you have received this file in error, please notify us and remove it from your system and note that you must not copy, distribute or take any action in reliance on it. Any unauthorized use or disclosure of the contents of this file is not permitted and may be unlawful. AstraZeneca PLC, 2 Kingdom Street, London, W2 6BD, UK, T: +44(0)20 7604 8000, F: +44 (0)20 7604 8151, www.astrazeneca.com