File - Emma Esperon

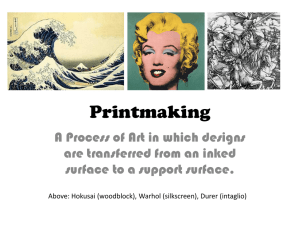

advertisement

The Dark Side of Iron Gall Ink: Corrosion and Conservation Presentation by Emma Esperon Library Studies 490 A Brief History Middle Ages to the 1900s. Predecessor: Carbon Ink Successor: Synthetic Inks Drafts of American Constitution Leonardo da Vinci’s Notebooks Ink Drawings Done by Rembrandt and Van Gogh Ingredients Tannin from Galls on Trees (below) Vitriol aka Iron Sulfate (left) Gum Arabic, the binding agent (bottom left) Water Ink Corrosion Evolution Model Environment and Handling 1604 1807 Signs of Corrosion Cracks Cause Holes in the Ink Bleeding and Discoloration Around the Ink Change of Ink Color and Opacity Risk Areas Large Areas of Ink Heavily Applied Treatments: Wash or Paper Simmering Submersion in Near Boiling Water 90°C Water for 15 minute increments Dissolves 50-100% of iron (II) ions most of the acids Consequences: paper shrinking, bleeding Treatments: Deacidification Aqueous Treatment Magnesium carbonate, Calcium bicarbonate, or Magnesium bicarbonate Prevents Acid Hydrolysis (starch sugar) Alkaline Treatment neutralizes the acids left by the Sulfate in the Vitriol The excess Iron remains in the document to rust over time Consequences: Paper Yellowing, Ink Bleeding Treatments: Phytate Calcium-Phytate / Calcium-Bicarbonate The Phytate chelates Binds the iron (II) and iron (III) ions Stops the Oxidation Process The calcium-bicarbonate is a deacidifer Neutralizes the acidic components of the ink Consequences: white powdered precipitate that can be easily brushed away No Treatment Original Blotting Sand Remains on Ink (right) Paper Simmering Consequences (below) Before Deacidification After Treatment removes Original Character of the record Treatment fundamentally changes the composition of the record Cannot Prove History: No Dating Provenance Authorship Thoughts? Preserve First! Cool Environment Low Moisture Conservation Calcium-Phytate / Calcium-Bicarbonate Method Lesser Side Effects No cracking, bleeding, blotting, fading, Stops the oxidation and the acid hydrolysis Works Cited Banik, Gerhard, et al. The Iron Gall Ink Website. Ed. Birgit Reissland and Frank Ligterink. European Commission on Preservation and Access, Bureau Metamorfoze, the Cultural Heritage Agency of the Netherlands, 13 Feb. 2011. Web. 16 Apr. 2012. <http://ink-corrosion.org/>. Louisiana Binding Service, Inc. "LBS-A Unique Line of Solutions: Deacidification." Document Preservation Specialists. N.p., n.d. Web. 16 Apr. 2012. <http://www.louisianabindingservice.com/solutions.html>. Morenus, Linda Stiber. “In Search of a Remedy: History of Treating Iron-Gall Ink at the Library of Congress.” The Book and Paper Group Annual 22 (2003): 119-125. Web. 16 Apr. 2012 PDF File. < http://cool.conservation-us.org/coolaic/sg/bpg/annual/v22/bp22-23.pdf>. Pedersoli, Jose Luiz, Jr., and Birgit Reißland. "Risk Assessment." N.d. PDF File. <www.viks.sk/chk/res_4_03_205_226.doc>. Reißland, Birgit, and Suzan De Goot. "Ink Corrosion: Comparison of Currently Used Aqueous Treatments for Paper Objects." N.d. PDF file. <cool.conservation-us.org/iada/ta99_121.pdf>. Shamayim, Melechet. "Dyo Making." The STa"M Forum. Ed. Eli Gutnick. Blogger, 1 Mar. 2012. Web. 16 Apr. 2012. <http://stamforum.blogspot.com/2012/03/dyo-making.html>. Schell, Laura. "Process." Laura Schell Paper Conservator. N.p., 2009. Web. 16 Apr. 2012. <http://www.paperconservationwny.com/process.htm>. Tse, Season, et al. "The Effect of Simmering on the Chemical and Mechanical Properties of Paper." Restaurator and Canadian Conservation Institute Newsletter 36 (Fall 2005): 14-35. Germany. Web. 16 Apr. 2012 PDF file. <http://www.viks.sk/chk/res_1_05_14_35.doc>.