Respiratory Protection Training

advertisement

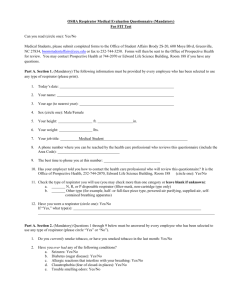

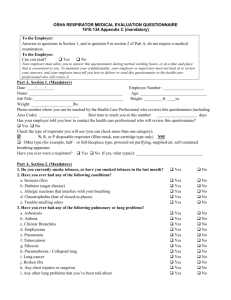

•Respiratory Protection Training Company Confidential – Do Not Distribute 1 EMERGENCY RESPONSE PLAN Evacuation Procedure in the event of a fire Trigger the Fire Alarm system by “pulling” or “pushing” the switch, long and loud sound will be heard. All employees, contractors and visitors must evacuate the building from the nearest fire door as soon as the alarm is heard. If visitor, let your guide Trane employee leads you to the nearest exit. Walk fast but do not run. Do not stop to return or pick up personal belongings until informed it is safe to do so. Proceed to designated Assembly area, remain and follow instructions. 2 In the event of a Fire R-Remain calm, do not panic. Rescue person in immediate danger. A-Alarm, Activate the nearest Manual Fire Alarm Switch C-Contain fire at point of origin by closing all doors and windows. Extinguish fire by using a portable fire extinguisher. (Unless you have been properly trained, never attempt to use a fire extinguisher) E-Evacuate the facility using establish procedure. 3 In the event of an Earthquake DROP to the ground; take COVER by getting next to a sturdy table or other piece of furniture until the shaking stops. If there isn’t a table or desk near you, cover your face and head with your arms and crouch in an inside corner of the building. Stay away from glass, windows, outside doors and walls, and anything that could fall, such as lighting fixtures or furniture. Note: If the walls are crumbling and the ceiling is falling in… In these conditions, the triangle of life created when a bookshelf, wall or part of a ceiling falls against a large piece of furniture is your best chance of not getting crushed. 4 In an event of Chemical Contamination Ask for assistance from any Trane personnel Wash contaminated clothing and body part under running water within 15 minutes. Use eyewash, shower station if available. STAY CALM, DO NOT PANIC! 5 1 Identify the PURPOSE: Respiratory Hazards 2 Understand the contaminants’ effect on workers’ health Four-Step Method 3 Select the appropriate respirator 4 Train in proper respirator use and care 6 What are Respiratory Hazards? Airborne Contaminants Particles Gases and Vapors Oxygen Deficiency 7 What are Airborne Contaminants? Particles • Dust: solid particles Dusts are formed as solid materials are broken into smaller particles, such as by drilling, sanding crushing or grinding. The smaller the dust, the longer it hangs in the air and the easier it is to inhale. Common dusts come from Asbestos, Fiberglas and Ceramic Insulation materials Aluminum, Galvanized Metal and Stainless Steel Coal and Carbon Products Minerals and ores Wood products 8 What are Airborne Contaminants? Particles Metal fumes Occur in high-heat operations, such as in welding and certain other types of metalworking Metal is melted, vaporized and quickly cooled in air Form very fine, small, solid particles that float in air Are often oxides of the vaporized metal 9 What are Airborne Contaminants? Gases Gases are substances that are neither liquids nor solids at room temperature and pressure. Gases can travel far and fast from their source, often undetected Gases occupy the space one places them in such as a cylinder. Common examples are Ammonia (NH3) Carbon Monoxide (CO) Chlorine (Cl2) Hydrogen Sulfide (H2S) Liquid Propane Gas (LPG) Ozone (O3) 10 What are Airborne Contaminants? Vapors Evaporated from liquids or solids Solvents Acetone Benzene Isopropyl Alcohol Mineral Spirits and Naphtha Products containing solvents Adhesives Glues Paints Mercury 11 How airborne contaminants occurs? Occurs when the percentage of oxygen in the air falls below a specified level < 19.5% by volume (US) Caused by oxygen consumption (chemical reaction, welding, fire) Other chemicals displace oxygen from the air (e.g. degreasing tanks) Often a concern in confined spaces (e.g. tanks, silos) Usually considered Immediately Dangerous to Life or Health (IDLH) Oxygen 21% Other Gases 1% Nitrogen 78% 12 13 Measure Exposure Concentration • Personal sampling – Sample is taken in worker’s breathing zone to estimate actual worker exposure • Area sampling – Used to assess concentration at a certain area or point Investigate confined spaces At contaminant source to estimate worst case exposure In middle of the room to evaluate effectiveness of general exhaust ventilation 14 Occupational Exposure Limits High Concentration Lower Explosive Limit (LEL) Ceiling, Immediately Dangerous to Life or Health (IDLH) 15 minute Short Term Exposure Limit (STEL) 8 hr Time Weighted Average (TWA) Action Limit Low 15 2 Understand the contaminants’ effect on workers’ health 17 Anatomy of the Lung 18 Importance of Lungs Surface area of alveoli is equivalent to the area of a tennis court Alveolar membrane is extremely thin (0.2 um) (equivalent length of 10-6 meters.) Used to transfer oxygen to blood and remove carbon dioxide Can also collect contaminants and/or distribute them to the rest of the body (systemic effects) 19 Inhalation Toxicology Acute Immediate response from a single short exposure Coughing, dizziness, nausea, sneezing, vomiting Acute effects aid in detection of exposure Chronic Delayed response from repeated exposure to low levels Decreased lung function, damage to other organs Caused by workplace exposure, living environment or life style (e.g., diet, drugs, tobacco) Gradual process, so may be difficult to detect 20 Normal Lung Very elastic Easy expansion and contraction The coloration of this illustration is due to iron siderosis minimal damaging effect 21 Cadmium Exposure Emphysema Symptoms: Difficult breathing lack of air likely to lead to cancer 22 Air Pollution Lung City air pollution 42 years old; unknown cause Color contrast lung tissue is evident - caused by air pollution 23 Foundry lung 36 years of exposure in a foundry Classic Silicosis 63 years of age Death by Cor Pulmonale 24 Welder’s Lung 34 years of exposure to welding fumes Siderosis and fever; fibrosis death at 52 years of age - cause unknown discoloration of pulmonary lung tissue 25 Mesothelioma - Cancerous lung 15 years of exposure to asbestos - textiles Asbestosis and mesothelioma (cancer of membranes that line chest and abdomen) 42 years of age at death pulmonary cancer cancer of the pleura 26 Smoker’s Lung with Cancer White area on top is the cancer, this is what killed the person. The blackened area is just the deposit of tars that all smokers paint into their lungs with every puff they take. 27 3 Select the appropriate respirator 28 Hierarchy of Hazard Control Techniques • Engineering Controls – – – – Change the process - eliminate the hazard Substitute a less hazardous material Enclose or isolate the operation or the worker Use local exhaust ventilation • Administrative controls – – – – Train workers on safe operating procedures Use good housekeeping practices Rotate employees in/out of exposed areas Conduct medical monitoring • Personal protective equipment – Only if other methods are not feasible, adequate or while they are being implemented 29 Respirator Classes Air Purifying Half Mask Full Facepiece Powered Air Purifying (PAPR) (half mask, full facepiece, loose fitting facepiece helmets or hoods) Atmosphere Supplying Supplied Air (half mask, full facepiece, loose fitting facepiece helmets or hoods) Self Contained Breathing Apparatus 30 Immediately Dangerous to Life or Health (IDLH) Environments Unknown environments Oxygen deficient environments or concentrations > IDLH Self contained breathing apparatus (SCBA) or combination Supplied Air/SCBA (ESCBA) Escape respirators (contaminant specific) 31 Non-IDLH Atmospheres Chose a particle and/or gas/vapor filter that will filter all of the selected contaminants If no suitable filter, then need supplied air respirators Cartridges or filters vary by country Select a respirator with an Assigned Protection Factor (APF) greater than the hazard ratio – APF is the amount that a respirator may reduce exposure e.g by a factor of 10, 100 etc. – APF is a function of respirator type and in some cases the type of cartridge or filter that is used 32 US APFs (as an example) Supplied Air Half mask 50 Full facepiece 1,000 Loose fitting facepiece Hood or helmet 1,000 33 34 Non-IDLH Atmospheres •Particulate Contaminants – Atmosphere supplying respirator SCBA Supplied air respirator 35 Activated Carbon Carbon derived from coconut shells or coal. Crushed and conditioned at high temperatures, low oxygen levels. Creates extensive network of internal pores and large internal surface areas. Organic vapors adsorb into micropores Micropores may be treated to react with certain gases and vapors (acid gases, ammonia, etc.) Not for filtering particles! 36 Cartridge Change Out Schedules • Must have warning properties below exposure limit, otherwise use supplied air respirators – Odor, taste, or irritation not always reliable indicators of end of service life • US – – – OSHA Regulations with mandatory change schedules for acrylonitrile, benzene, butadiene, formaldehyde, methylene chloride, vinyl chloride End of service life indicator (ESLI), or Service Life Software™ on 3M website Helps determine when customers need to change cartridge 37 Other Concerns Regarding Selection • Comfort • Facial fit (multiple sizes?) • Maintenance (reusable vs. disposable) • Non respiratory hazards – Impact protection (head, eye, face) – Visible and UV light (e.g., welding) – Splash or eye irritation • • • • • Compatibility with other PPE Communication Medical fitness of wearer Mobility requirements Facial hair 38 4 Train in proper respirator use and care 39 Training • Why respirator is necessary – Contaminants – Health effects • Limitations and capabilities of the respirator – Helps reduce exposure to ______ – Does not reduce exposure to ______ – (If applicable) Does not supply oxygen • Demonstrate how to put on the respirator and have them practice • Need to properly fit, maintain and wear respirator in order for it to work properly • Decontamination of Respirator 40 User Seal Checks Positive Pressure Negative Pressure •To be conducted each time before entering contaminated environment 41