Atomic Layer Deposition of Cerium Oxide Thin-films

advertisement

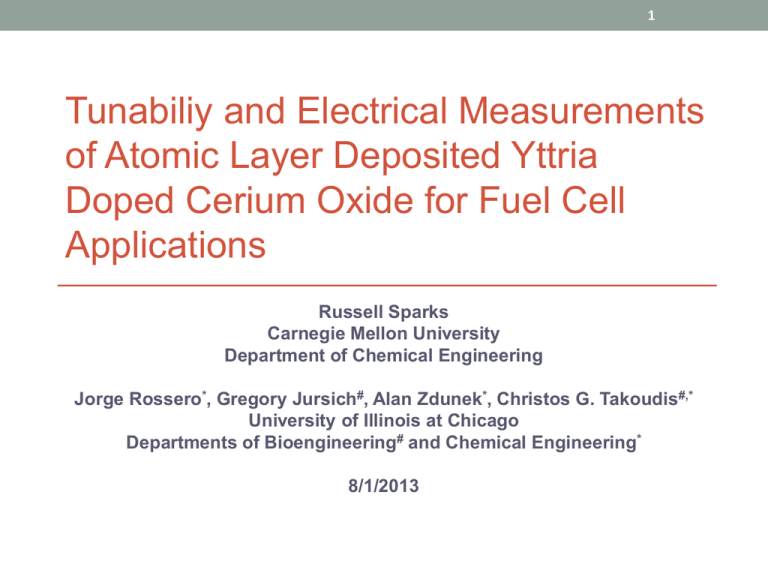

1 Tunabiliy and Electrical Measurements of Atomic Layer Deposited Yttria Doped Cerium Oxide for Fuel Cell Applications Russell Sparks Carnegie Mellon University Department of Chemical Engineering Jorge Rossero*, Gregory Jursich#, Alan Zdunek*, Christos G. Takoudis#,* University of Illinois at Chicago Departments of Bioengineering# and Chemical Engineering* 8/1/2013 2 Applications and Advantages of Solid Oxide Fuel Cells (SOFCs) Advantages Applications • SOFCs could become • Stationary electrical clean replacements for fossil fuel • SOFCs do not produce NOx, SOx, or hydrocarbon emissions • Reduced CO2 emissions • Fuel flexibility-SOFCs can use alternative fuels such as H2 power generation • Replacement for car batteries N. Perdikaris, K. D. Panopoulos, P. Hofmann, S. Spyrakis and E. Kakaras, International Journal of Hydrogen Energy, 2010, 35, 2446-2456. J. Kupecki, J. Milewski and J. Jewulski, Central European Journal of Chemistry, 2013, 11, 5, 664-671. 3 SOFC Background • Current SOFCs require operating temperatures >800 °C • Reducing this to 500-600 °C would greatly increase SOFC utility • CeO2 increases O2- ion conductivity at lower temperatures by creating oxygen vacancies in the electrolyte • Several physical and chemical methods exist to deposit CeO2 and Ceria-based materials (YDC) Schematics of a planar SOFC 4 Yttrium doped Cerium (YDC) • Ce4+ in the electrolyte tends to reduce to Ce3+ in the anode, increasing the electric conductivity and causing the cell to short circuit • Adding Y to Ce film tends to stabilize Ce4+ ions and allow higher O2- conductivity through vacancies in the lattice structure • Research indicates optimal Y concentration to be 20-34 % Z. Fan, C. Chao, F. Hossein-Babaeiaand, F. B. Prinz, J. Mater. Chem., 2011, 21, 10903. Z. Li, T. Mori, D. Ou, F. Ye, G. J. Auchterlonie, J. Zou and J. Drennan, The Journal of Physical Chemistry, 2012, 116, 5435-5443. 5 Atomic Layer Deposition (ALD) • Gaseous ligand precursor is pulsed over Si substrate • Metal ion reacts with –OH on substrate • Reaction is self-limited by amount of –OH on substrate surface • Oxidizing gas is pulsed to react with metal ions • –OH tails present for next ALD cycle ALD Process Schematic* *J. Päiväsaari, Inorganic Chemistry Publication Series, Helsinki University of Technology, 2006. 6 ALD • Tris[isopropyl-cyclopentadienyl]cerium (Ce(iPrCp)3) and Tris[isopropyl-cyclopentadienyl]yttria (Y(iPrCp)3) precursors and water are used to deposit CeO2 and Y2O3 onto Si substrates • Water reacts selectively with metal-ligand bond in ALD precursors • Common ligand Ce(thd)4 only reacts with O3 thd = 2,2,6,6-tetramethyl-3,5-hepadionate 7 Experimental Setup* Ice bath Hot wall reactor * P. Majumder, et al., Journal of The Electrochemical Society, vol. 155, pp. G152-G158, 2008. 8 Electrical Resistivity • Ce+4 has high ionic • • • • conductivity, Ce+3 has less ionic conductivity Electric resistance inversely proportional to ionic resistance Film surface resistivity measured by four-terminal sensing Resistivity measured by labbuilt sensor Sensor consists of 4 Pt electrical leads resting on a nonconductive surface to measure resistance 9 Electrical Resistivity (cont.) • LCR instrument was calibrated to determine best operating conditions • >2 V and 100-200 Hz settings were found to give most precise resistance readings • Wide range of YDC, Si, and CeO2 samples tested • Thickness: 6-28 nm • Weight added on top of sample: 0-50 g • Voltage Range: 0.20 V-5 V • Frequency Range: 10 Hz-100,000 Hz • 2 V DC bias added to overcome effects of frequency • 20, 30 %Y content in YDC films • Annealed and non-annealed YDC films 10 Sheet Resistance (MΩ-Sq) Sheet Resistance of 20% YDC Films with Added Weight 9 • Extra weight may 8 cause wire leads to rub through film • Substrate resistance instead of film resistance measured • Negative readings caused by resistances too high to result in readings 7 6 5 11 nm 4 22 nm 28 nm 3 2 1 0 0 10 20 Added Weight (g) Samples were analyzed with 75 Hz and 2V. 11 Effects of Annealing 20 %Y YDC Sample Sheet Resistance (MΩ-Sq) 10 8 1 V Non-Annealed 6 2 V Non-Annealed 4 3 V Non-Annealed 2 4 V Non-Annealed 0 5 V Non-Annealed 0 100 200 300 400 500 Sheet Resistance (MΩ-Sq) Frequency (Hz) 10 8 1 V Annealed 6 2 V Annealed 4 3 V Annealed 2 4 V Annealed 0 0 100 200 300 Frequency (Hz) 400 500 5 V Annealed 12 Sheet Resistance (MΩ-Sq) Sheet Resistance vs. Frequency of YDC Films 10 8 1V 20% Y YDC 6 2V 20% Y YDC 4 3V 20% Y YDC 2 4V 20% Y YDC 0 0 50 100 150 200 250 300 350 5V 20% Y YDC Sheet Resistance (MΩSq) Frequency (Hz) 10 8 1V 30% Y YDC 6 2V 30% Y YDC 4 3V 30% Y YDC 2 4V 30% Y YDC 5V 30% Y YDC 0 0 50 100 150 200 Frequency (Hz) 250 300 350 13 Sheet Resistance (MΩ-Sq) Effects of 2 V DC Bias for 20% YDC Films 10 8 1V Without Bias 6 2V Without Bias 4 3V Without Bias 2 4V Without Bias 0 0 100 200 300 5V Without Bias 400 Sheet Resistance (MΩSq) Frequency (Hz) 10 8 6 1 V With Bias 4 2V With Bias 3V With Bias 2 4V With Bias 0 0 50 100 150 200 250 Frequency (Hz) 300 350 400 450 14 YDC Film Stoichiometric Tunability 0.8 0.7 Y-atom ratio Y/(Y+Ce) 0.6 0.5 0.4 y = 1.00x + 0.062 R² = 0.9994 0.3 0.2 0.1 0 0 0.1 0.2 0.3 0.4 0.5 ALD CYCLE RATIO Y/(Y+Ce) 0.6 0.7 0.8 15 XPS Background • XPS (X-Ray photoelectron spectroscopy) measures kinetic energy change of spectral emissions • Sensitivity analysis calculates the atomic percent composition of each component element by comparing peak areas • XPS can determine Ce4+/ Ce3+ and Ce/Y ratios based on their respective peak sizes 16 XPS Results for 20 % Y YDC film • 23% Ce3+ in this sample. • V0, U0 and V’, U’ indicate Ce3+, other peaks for Ce4+. • Peak sizes analyzed using Pfau-Schierbaum method Binding Energy I.D 880.32 Vo 882.21 V 884.75 V' 888.55 V" 898.2 V"' 899.2 Uo 900.81 U 903.14 U' 907.13 U" 17 Conclusions • Yttria doped cerium oxide films were successfully • • • • • deposited via ALD using Ce(iPrCp)3, Y(iPrCp)3 and water XPS analysis shows that by increasing the ALD cycle ratio (Y:Ce) the concentration of Yttrium was linearly increased in the film Annealed and non-annealed resistances are close and have same order of magnitude Higher Y concentration had little effect on measured resistance 3 V and 150 Hz produce most accurate resistance results DC bias unnecessary 18 Recommendations for Future Experiments • Produce resistance probe station capable of taking resistance measurements up to 800 °C • Repeat calibration measurements at high temperature • Goal: Determine precise YDC doping for maximum electrical resistance 19 Acknowledgments • I would like to gratefully acknowledge the financial support provided by: • EEC-NSF Grant #1062943 • CBET-NSF Grant #1346282 • I would like to gratefully acknowledge the material support provided by: • Advanced Materials Research Lab, University of Illinois at Chicago for use of laboratory facilities • Air-Liquide USA for providing precursors 20 References • M. Fanciulli and G. Scarel (Eds.): Rare Earth Oxide Thin • • • • • Films, Topics Appl. Physics, 106, 15–32 (2007) © Springer-Verlag Berlin Heidelberg 2007. M. Coll, J. Gazquez, A. Palau, M. Varela, X. Obradors and T. Puig, Chem. Mater. 2012, 24, 3732−3737. W. Kim, M. Kim, W. J. Maeng, J. Gatineau,d, V. Pallem, C. Dussarrat, A. Noori, D. Thompson, S. Chu and H. Kima, Journal of The Electrochemical Society, 158 (8) G169G172 (2011). Z. Fan, C. Chao, F. Hossein-Babaeiaand and F. B. Prinz, J. Mater. Chem., 2011, 21, 10903. P. Gao, Z. Wang, W. Fu, Z. Liao, K. Liu, W. Wang, X. Bai and E. Wang, Micron, 2010, 41, 301-305. 21 Atomic Percent Comparison (PfauSchierbaum Analysis) • 22 Atomic Percent Comparison •