Presentation PowerPoint

advertisement

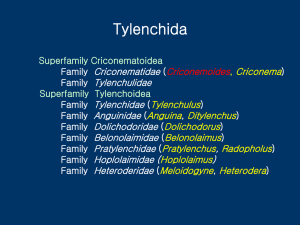

Dr. Gary Peter Professor University of Florida Southern Pines: The Bioenergy & Renewable Chemicals Star of the Southeastern US Gary Peter University of Florida gfpeter@ufl.edu Pine Forests of the Southeastern US • Forests occupy over 200 million acres (60% of the land area), with a large fraction dominated by pines – 10 species, loblolly and slash economically important • ~85% of all forestlands are privately owned • About half the pine forest is planted with genetically improved seedlings – About 10 million ha / 25 million ac each • Contains 12 Pg of C, 36% of the sequestered forest C in the contiguous United States • Annually sequester 76 Tg C, equivalent to 13% of regional greenhouse gas emissions US South: Forestry & Forest Industry • Largest biomass industry in world – Produces 16% of global industrial wood supply • More than any other country – Supplies 60% of US & 25% of world pulp & paper markets • 43 million tons of annual capacity • Generates ~2/3’s of all industrial bioenergy – Used on site • Sustainability is a key focus for industry – >93% of stem is utilized Johnson & Steppleton, 2011 Southern pulp mill location & capacity Forest Products Supply Chain Feedstock production Feedstock logistics Biomaterials • Scalable – Large land area – Large stable markets • Sustainable – More volume growth than harvested • Cost competitive for traditional products – Pulp, paper, wood Distribution & use Operating & Proposed Wood Biomass to Electric Power & Wood Pellet Facilities Approx. 30 actual or proposed plants Approx. 40 actual or proposed plants TimberMart-South Biofuel Production in the Southeast • 2010 USDA biofuels report estimates that ~50% of the advanced biofuel production capacity will be located in the southeast US – Most favorable growing conditions & available land • Advanced biofuel facilities that can use pine feedstock – – – – KiOR (thermochem) Bluefire (acid hydrolysis) Ineos (thermochem) Bluesugar ? Stable Cost & Large Supply Since 1940s, planted pine productivity has tripled, primarily due to improved genetic stock and silvicultural technology developed and disseminated by University / Government / Industry Research Cooperatives 50 6000 40 4000 30 20 2000 10 0 Rotation age (years) 60 Volume at Harvest (ft3 / ac) 8000 0 1940 1950 1960 1970 1980 1990 2000 2010 Establishment Decade Natural Stand Weed Control Planting Tree Improve Site Prep Biotech/Clonal Fertilization Rotation Age Redrawn from: Fox, T.R., E.J. Jokela and H.L. Allen. 2007. The development of pine plantation silviculture in the southern United States. J. Forestry 105:337-347. 70 Range: 0.980 ~ 1.051 60 Mean: 1.001 50 60 Density Density Traditional Phenotypic Breeding with Recurrent Selection 70 SD: 0.00519 40 Mean: -0.00026 50 SD: 0.00455 40 30 30 20 20 10 10 0 0 Phenotype: Total Height Diagonal elements of genetic relationship matrix (Rarw estimates) 140 120 c 120 Range: 0.983 ~ 1.043 Density SD: 0.00434 60 Range: -0.0190 ~ 0.0214 80 Mean: 1.001 80 Mean: -0.00021 60 SD: 0.00380 40 40 20 20 0 Quantitative Trait d 100 100 Density Off-diagonal elements of genetic relationship matrix (Rarw estimates) 0 Supplementary Figures Off-diagonal elements of genetic relationship matrix (Adjusted estimates) Diagonal elements of genetic relationship matrix (Adjusted estimates) 100 0.690 e 80 SD: 0.00519 40 40 Variance Components P= G + E G= A + D + I -Heritability (h2) -G x E c -G x Age 3.9 2.9 2.4 1.9 1.4 0.9 0.4 -0.6 -1.1 -1.6 -2.1 Diagonal elements of genetic relationship matrix (Rarw estimates) -2.6 -3.1 -3.6 -4.1 0 3.4 0.1 Z-score SD: 0.00455 Breeding Values -Ranking genotypes -Selection Off-diagonal elements of genetic relationship matrix (Rarw estimates) 120 d 100 Range: 0.983 ~ 1.043 80 Range: -0.0190 ~ 0.0214 Supplementary Figure 1 Histograms of (a) the diagonal and (b) the off-diagonal elements of Mean: -0.00021 Mean: 1.001 80 60 SD: 0.00434 Density Density Mean: -0.00026 50 0 0 b Range: -0.0227 ~ 0.0256 10 10 Phenotype = X b + Za + e 60 20 20 BLUP 70 30 0.330 100 Density 0.450 120 80 Mean: 1.001 -0.1 Density Density 60 140 90 Range: 0.980 ~ 1.051 0.570 0.2 100 a 60 SD: 0.00380 the raw estimates of the genetic relationship matrix, (c) 40 the diagonal and (d) the off-diagonal 40 20 20 0 0 Nature Genetics: doi: 10.1038/ng.608 Diagonal elements of genetic relationship matrix (Adjusted estimates) Off-diagonal elements of genetic relationship matrix (Adjusted estimates) CFGRP: Slash Pine Deployment Gains & Value Genetic Gains in Harvest Yields (%) 50 40 30 20 10 0 Low Hazard 1.0 Unrogued 1.0 Rogued 1.5 Unrogued 2.0 Unrogued 2.0 Rogued 2.5 Unrogued 3.0 Unrogued Conservative estimate of incremental increase in stumpage value (6% interest) due to increased yields from planting genetically improved stock in FL estate $ in millions 600 500 400 300 200 100 0 1 2 3 Cycle of Genetic Improvement Source: Greg Powell, Univ Florida Pine Breeding Cycle Pine Breeding is a long multi-step process >30 years 1st to 2nd Generation Reduction of more than 10 years: White et al. 2008 -Early Selection -Smaller populations -Top-grafting Can be partitioned in three stages Breeding Testing Propagation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Start Breeding Commercial Production Marker Assisted Selection B. Indirect markers based on linkage disequilibrium: I - QTL analysis III – Genomic selection II – Genetic association Resolution Low Medium High Linkage Blocks Large Medium Small Genome-Wide Selection Training population Phenotypes Genotypes Fit all SNPs in a prediction model Validation Y = SNP + e Define multi-loci models to predict phenotypes Meuwissen et al. (2001) Genetics 157: 1819-1829 Genomic Selection “Current status in breeding” • Genomic Selection is operational in cattle breeding and evaluated in other animals, crops and trees • Focus has been on development of methods (e.g. GBLUP, RR-BLUP, Bayes A, Bayes B, LASSO, RKHS, Machine learning, etc.) • Everybody agrees that GS application depends on the accuracy of predicting phenotype with markers • Theoretically accuracy depends on: – – – – Linkage disequilibrium extent Training population size Heritability Number of QTLs • But also depends on the BV quality used to construct the GS model GWS Accuracies in CCLONES DBH & Height 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 DBH HT B.F. Grant Cuthbert BV / Yr Nassau Palatka Accuracy Intensity Generation Variation Interval GWS Incorporated into Pine Breeding 10+ years 8+ years 8+ years B T P 8+ years B T 4 years 8+ years <1yr 4 years <1yr 1 2 3 4 5 6 7 8 9 10 12 13 14 15 16 17 18 19 20 21 22 23 24 25 P B T P TP B 1 2 3 4 5 4 years 1yr B 4 years 1 2 3 4 5 6 7 8 9 10 12 13 14 1yr 4 years 1yr 1 2 3 4 5 6 7 8 9 10 12 13 14 TP B TP 1 2 3 4 5 1 2 3 4 5 Conifer Oleoresin Canal System for Insect and Fungal Resistance • The wood resin canals (vertical and horizontal) are organized into a 3D network for terpene synthesis and storage – Thin walled resin canal epithelial cells line the canal and synthesize and secrete terpenes into the lumen of the canals or duct Resin canals • Resin flows out of stem after wounding, typically by boring insects – Constitutive resin under positive pressure in resin canals Why Terpenes? Terpenes as Biofuels • High energy density - carbon and hydrogen rich and low in oxygen • Simple & efficient chemical methods for conversion of natural terpenes to drop-in fuels suitable for blending or replacement of petroleum are available – b pinene dimers as a jet fuel replacement – Bisabolene to bisabolane a D2 diesel fuel replacement – Farensene as a diesel fuel Terpene Biosynthesis • Conserved biosynthetic pathways in microbes & plants • Large variety of natural terpenes with varying chemical properties – Mono, sesqui-, di- and triterpenes Biofuels & Co-products 1st GENERATION BIOFUELS Extraction •Sugar – Ferment to EtOH – Sugar •Starch – Amylase + ferment to EtOH – Oil, animal feed •Oil – Transesterification to biodiesel – Glycerin 2nd GENERATION BIOFUELS Deconstruction •Lignocellulose – Sugar Platform • Size reduction + degradation + fermentation • Power, lignin – Gas Platform • Anaerobic digestion to biogas • Gasification + catalytic synthesis to liquid fuel • Power – Liquid Platform • Cracking / pyrolysis + upgrading Conversion of Biomass to Fuel Extraction Based • Compound highly concentrated in biomass that facilitates efficient recovery • Starting material has high chemical uniformity • High efficiency conversion with limited input costs Deconstruction Based • Biomass is large & heterogeneous • Starting material has relatively low chemical uniformity • Requires substantial energy and/or chemical inputs to reduce Come from domesticated plants breed & selected for concentration & yield of food Non-edible parts of food plants & undomesticated grasses & trees Pine Terpenes • Naturally synthesize a • Terpenes accumulate in large diversity of mono-, wood naturally to >20% sesqui- and diterpenes – Constitutive synthesis as defense compounds – Inducible synthesis against insects & fungi • Genetic and environmental control of wood terpene content Current Pine Terpene Industry Pine Biosynthesis Extraction Live Tree Pulp Mill Wood Rosin Crude Products Gum Turpentine & Rosin CTO & CST Wood Turpentine & Rosin Final Products Industrial Biofuels Specialty Chemicals Flavors & Fragrances Pine Terpenes: A $3 Billion Global Industry • Pine Terpene collection > 1 billion tonne/yr – Turpentine (mono- & sesquiterpene) rosin (diterpenes) – Gum terpene (60%), crude sulfated turpentine & crude tall oil (35%), wood naval stores (5%) • Gum terpenes collected by tapping living trees > 850,000 tonne/yr – China, Portugal, USSR, Brazil, Indonesia, Mexico, India – China >500,000 tonne/yr [60% of global supply but little is exported] • Pulp & paper industry collects terpenes as a co-product – Crude sulfated turpentine & Crude tall oil (CTO) – US south 450,000 tonne/yr of CTO Phenotypes Intensity (arb units) Oleoresin drymass Resin canals Wood terpene content • Box-Cox transformed oleoresin • Number of resin canals per • Diterpene content in dry drymass exuded over 24 hours year (averaged over triplicate wood • 1002 cloned genotypes samples) • 940 cloned genotypes • 3 sites • 543 cloned genotypes • 2 sites • 3 clonal replicates per site • 3 sites • 2 clonal replicates per • 3 years (one site) • 3 clonal replicates per site site • 2 years • Total, mono- & diterpene content in wet wood • 750 cloned genotypes • 1 site • 4 clonal replicates per site 14 12 10 8 6 4 2 0 93 302 204 30 80 130 180 230 280 330 380 430 m/z Oleoresin traits are heritable H2 resin canal number •single site: 0.15 – 0.21 •across sites: 0.12 H2 oleoresin drymass •single site: 0.18 – 0.34 •across sites: 0.18 Phenotypic variation in oleoresin drymass is positively skewed Oleoresin drymass by site Xylem growth increment per year Resin canal number per year Associated SNPs accurately predict additive genetic variation in oleoresin drymass Estimated F1 genetic gains in oleoresin drymass under varying selection intensities h2 Fold-increase breed top 10% Fold-increase breed top 5% Fold-increase breed top 1% CUT 0.14 1.62 1.74 1.98 NAS yr 6 0.31 1.86 2.05 2.41 NAS yr 7 0.24 1.80 1.98 2.33 PAL 0.12 1.54 1.61 1.77 ALL 0.12 1.61 1.72 1.92 site h2: narrow sense heritability TE-Pine Can Exceed PETRO Metrics Plants Engineered To Replace Oil Increase the mass of readily extractable hydrocarbons to meet technical targets at costs competitive with crude oil Technical Targets Value Required 1.1-Energy density > 26.5 MJ/L (LHV) 1.2–Melting point < -40oC <-63oC 1.3–Boiling point > 35oC >135oC 1.4-Energy 1.5-Process cost 2.1- CO2 use 2.2- H2O requirement > 160 GJ ha-1 y-1 < $10 GJ-1 Atmospheric CO2 > 160 GJ ha-1 y-1 < $10 GJ-1 Ambient < 22 inch y-1 No irrigation <201 kg ha-1 y-1 N, <77 kg ha-1 y-1 P, <56 kg ha-1 y-1 K 58.5 kg ha-1 y-1 N, 7.5 kg ha-1 y-1 P 2.3- Fertilizer requirement HT- Pine • Scalable – 13 million+ h planted pine exist – Yield gains achievable • Environmentally Sustainable – High harvest index – Strong positive net energy – Strong negative CO2eq • Economically Sustainable – Lignocellulose & terpene coproduct synergy – Adds value across supply chain • Adds Flexibility – No clear detrimental change in current product mix – Strengthens possibility of pine as a dedicated biofuel crop – Multiple routes to extraction Discovery phase Genetic engineering to rapidly increase oleoresin production in pine stems Association genetics •Multi-site analysis of correlated oleoresin traits in a structured clonal population Gene expression • Differential expression with chemical elicitors of resinosis • Tissue-specific expression in resin canals Candidate genes Validation phase • RNAi mediated silencing • Overexpression • Wild-type v. mutant phenotypes Project Overview • To increase terpene production 5 fold Three Synergistic Strategies for Increasing Pine Terpene Synthesis & Storage Will Be Used Activation Triple Resin Capacity Constitutive Resinosis Pathway 25% Greater Flux Upregulate Carbon Flux to Terpenes Enzyme 1.5X Faster Synthesis Optimize Composition & Production of Terpenes Terpenes & the Future Forest Biorefinery Issue Alignment • Land Use • Environmental Sustainability • Conversion Efficiency • Cost effective • Net positive energy relative to fossil fuels • Dramatic increase in GJ/ha/y • Increased value to landowners sustains forest land • Extracted as a co-product – lignocellulose still useful for all traditional products or energy • Existing capital • Flexible end product markets • Strongly positive to fossil fuels Acknowledgements COLLABORATORS • University of Florida – John Davis, Chris Dervinis, Matias Kirst, Patricio Munoz, Marcio Resende, Alejandro Riveros-Walker, Jared Westbrook • ArborGen – Will Rottmann • NREL – Mark Davis, Robert Sykes • University of California, Berkeley – Jim Keasling, Jim Kirby, Pamela Peralta-Yayha, Blake Simmons FUNDING • DOE/ARPA-E • USDA/NIFA • Forest Biology Research Cooperative – Plum Creek Timber, Rayonier, Weyerhaeuser, RMS, F & W Project Summary Resinosis Improved enzymes Increased carbon flux Discovery Increased Resin canal #/volume Increased terpene synthesis Combinatorial engineering Five fold increase in wood terpene 20% wood terpene Technoeconomic Modeling Forest tree growth Value Chain Analysis & Proposition Terpene recovery Commercialization Partners Germplasm providers Fuel production Landowners Harvesting/transport Wood processors Fuel synthesis Pulp & paper Biofuel Producers Wood products Bioenergy Oleochemical Refiners Flavor & Fragrances Dr. Gary Peter Professor University of Florida