MS PowerPoint

advertisement

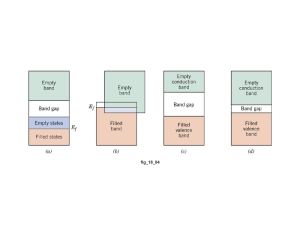

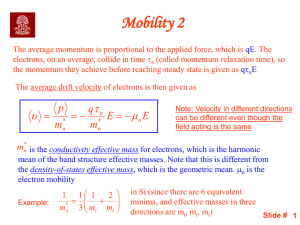

Electrical conductivity & Catalysis Dr.K.R.Krishnamurthy NCCR,IITM Catalytic activity & Electronic states Catalysis Chemisorption Catalyst ↔ Reactant/ Product Charge transfer (Adsorption/Desorption) Electronic levels in catalyst Electrical conductivity Electronic structure of solids Electronic states /Structure-Metals Band Theory of solids Electronic states- Non metals/Oxides Band structure & Concept of charge transport Charge carriers- Electrons/Holes Energy band diagram of solids Electrons in outer most orbitals interact to form energy bands Reactivity determined by the energy levels Conduction band Conduction band Energy gap Valance band Metal Continuous energy levels Partially occupied Free movement of electrons Semi-conductor Filled valence band Empty conduction band Forbidden gap Energy needed to transport electrons Thermal, doping Valance band Insulator Filled valence band Empty conduction band Band gap very high Typical > 4.0eV Doping Fermi level- Concept & Significance At T= 0K, energy levels up to Fermi level (EF) are occupied & levels above EF are empty At T1& T2 (T2>T1>0 K) due to thermal excitation some levels above EF are filled EF represents thermodynamic chemical potential for electrons in solids When two metals or semi-conductors or metal – semiconductor are in electrical contact, electrons will flow from the solid with higher EF to the one with lower EF till the Ee in both are the same For intrinsic semi-conductors, Ef represents a state where the probability of finding electron is ½ Location of EF may change depending up on n- or p- type semi-conductivity Fermi level- Significance For pure semiconductor Fermi level falls in the Middle of band gap E-EF = Eg n = e(-Eg/2kT) – n= No of charge carriers excited Emergy levels in solids Bending of energy levels Bending of energy levels Bending of energy levels Conductors- Classification Energy levels- Semiconductors Conduction band Conduction band Donor levels ----------------------------- Acceptor levels ---------------------------------Valance band Valance band Intrinsic semiconductors- No impurity levels; No.of electrons = No.of holes Extrinsic semi conductors- Conductivity due to doping Donor levels – Electrons as charge carriers –n-typeAcceptor levels – Holes as charge carriers – p-type Type of semi-conductors- Examples n-Type Doping of P with 5 electrons in Si with 4 electrons Creation of donor levels below CB Electrons from donor level can be excited to CB Charge carriers -Electrons p-Type Doping of Boron with Si with 4 valence electronsCreation of Acceptor levels above VB. Electrons transferred to acceptor level leaving holes in VB Charge carriers- Holes Dopants M(n+m)+ n-type Mn+ Matrix M(n-m)+ p-type Electrical conductivity Electrical conductivity σ = neμe + peμp n &p- No of electrons & holes e- Charge of an electron,1.602 x 10-19 coloumbs μe & μp –Mobilities of electrons & holes expressed in cm2 /Volt-Sec ; Electrons 2.8 times more mobile than holes For intrinsic semi conductors n= p Hence, σ = ne(μe + μp ) In the case of extrinsic semi-conductors Both carriers contribute towards conductivity Concentration of majority type carriers determine the type of conductivity- ie., n- or p-type This will also be reflected in Hall and Seebeck coefficients Electrical conductivity- Temperature effect Lnσ ↑ Intrinsic region Exhaustion region Extrinsic region 1/T → Electrical conductivity σ = σ0 e(-Eg/2kT) ; Eg= EC –EV Eg- Band gap; Slope in intrinsic region= Eg/2k Chemisorption & Electronic states Chemisorption- Charge transfer between catalyst & reactants Reactant R on accepting an electron RCharge transfer may not be complete, but partial- Chemisorptive bond With R- on surface, induces + charges below the surface Emergence of + vely charged layer retards further flow of electrons to the surface- R- species- Depletive chemisorption ExamplesOxygen adsorption on ZnO- n-type semiconductor Oxygen adsorption on p-type semiconductor- NiO-Cu2O- Cumulative chemisorption H2 chemisorption on ZnO- Cumulative These charge transfers can be followed by measurement of electrical conductivity of solids EUROCAT- V2O5-WO3-TiO2-In-situ Electrical conductivity studies Conductivity of Oxide catalysts Semi-conducting characteristics- TiO2- n-type semiconductor Electrical conductivity is a function of: Surface structural defects Adsorbed species Reduced/Oxidized species/states Dissolved ionic impurities Supported metal oxides- Support & Active phase- Which one contributes? Conductivity- related to the support Percolation threshold- 40 % min- for active phase to contribute Active-phase-support interactions could play key role- Modify support conductivity V2O5,WO3 & TiO2- n-type semi-conductors 6NO + 4NH3 5N2 + 6H2O 333.5 kcal=mol – Reducing atmosphere 4NO + 4NH3 + O2 4N2 + 6H2O 291.4 kcal=mol- Oxidizing atmosphere In-situ Electrical conductivity measurement Conductivity σ = (1/R)*(t/S) R- Resistance in Ohms T- Thickness of pellet ,cm S- Cross sectional area, cm2 M.Breyesse et.al, J. Catalysis. 27, 275,1972 EUROCAT- V2O5-WO3-TiO2-In-situ Electrical conductivity studies Factors responsible for activity the stability of surface vanadium oxide phase on titania The structure of the deposited vanadium oxide phase the strength and the number of V=O bonds The acidity of the surface vanadium oxide and the ease of reduction of the supported vanadium oxide catalyst. Electrical conductivity measurements could be used to study many of the factors above, besides the behaviour of the catalyst under in-situ reaction conditions Oxidation/reduction conditions Establishing surface transformations & reaction mechanism Titania- Origin of conductivity Dissolved V & W ions lead to formation of delocalized electrons responsible for electrical conductivity Ionic size critical for substitution in lattice Conductivity in different atmospheres Introduction of 230 mg of catalyst in the cell & evacuation at room temp. Introduction of 400 Torr of oxygen Heating at 5°C/min up to 300°C and attaining of the steady-state conductivity Evacuation of oxygen and introduction of 1.52 Torr; NO which corresponds to the partial pressure of 2000 ppm NO Evacuation of NO and introduction of 2000 ppm NH3 Evacuation of NH3 and re-admission of NO to check the reversibility of the electrical conductivity under NO atmosphere; Evacuation of NO and admission of the reaction mixture (NO+NH3) 2000 ppm each to follow in- situ the redox processes during reaction; Evacuation of the reaction mixture and introduction of 400 Torr O2 to follow the reoxidation of the catalyst; Evacuation of O2 and introduction of a second reaction mixture (NO+NH3) to follow σ variations under reaction mixture. Changes in electrical conductivity Ionosorption of NO with electron Capture NO(g) + e− NO−(ads) V0+ + NON0 + N0 Fig. 2. First exposure to 2000 ppm NO of WO3/TiO2 and V2O5–WO3/TiO2 in an oxidized state and after a prompt outgassing, recorded at 573 K. N0 +O2-s N2 Electrons drawn from titania are delocalized Electrons are transferred from the active phase to the support Increase in conductivity is due to the interaction between adsorbed NH species and NO- A resultant increase in conductivity Fig. 6. Exposure to the reaction mixture (2000 ppm NO ~2000 ppm NH3 ~500 ppm O2) of WO3 /TiO2 and V2O5–WO3/TiO2 (fresh and used) catalysts in an oxidized state, recorded at 573 K. Surface transformations-Summary NO alone and in the absence of oxygen has an electron acceptor character since δσ/δPNO <0, forming NO- ionosorbate and/or filling anionic vacancies. NH3 has a reducing character since δσ/δPNH3 >0. The SCR reaction mixture (1 NO (2000 ppm)+NH3 (2000 ppm)) has also a reducing character with respect to the surface of V2O5/WO3/TiO2 catalyst,either in a slightly reduced state (Fig. 5) or in an oxygen-containing atmosphere (Fig. 6). Therefore, two different cases have to be envisaged Surface transformations w/o Oxygen Surface transformations w/o Oxygen Surface transformations with Oxygen Surface transformations with Oxygen Electrical conductivity of Cs doped NiMoO4 α- NiMoO4- n-type semi-conductor Cs is available on the surface & does not affect molybdate structure Increase in conductivity with Cs due to ionic conductivity At high Cs loading- loss of dispersion due to growth of Cs particles Conductivity of Cs doped NiMoO4 Conductivity of NiMoO4 Defects in the form of anionic oxygen vacancies are responsible for n-type conductivity Conductivity of NiMoO4 in Oxygen Seebeck Effect A temperature difference between two points in a conductor /semiconductor gives rise to a voltage difference between these two points That is , a temperature gradient in a conductor results in an electric field This effect is called Seebeck Effect or thermo electric effect Thermo electric voltage developed per unit temperature difference is called Seebeck coefficient Only the net Seebeck voltage between two different metals can be measured The principle of thermocouples is based no Seebeck effect S = dV/dT Seebeck effect The thermopower/emf of a material, represented as S, depends on the material's temperature, and crystal structure Typically metals have small thermo emf because most have half-filled bands. Electrons (negative charges) and holes (positive charges) both contribute to the induced thermoelectric voltage thus canceling each other's contribution to that voltage and making it small. In contrast, semiconductors can be doped with an excess amount of electrons or holes and thus can have large positive or negative values of the thermopower depending on the charge of the excess carriers. The sign of the thermopower can determine which charged carriers dominate the electric transport in both metals and semiconductors. Superconductors have zero thermopower since the charged carriers carry no entropy. Equivalently, the thermopower is zero because it is impossible to have a finite voltage across a superconductor. (For example, by Ohm's law, V=IR=0, since the resistance, R, is equal to zero in a superconductor.) Seebeck effect Seebeck Effect Seebeck effect Seebeck effect Seebeck Effect Seebeck Coefficient- Measurement A- Sample held between two metal clamps Th- Thermocouples attached to the sample in iso-thermal region Temperature and potential must be taken at the same point inside the sample. Mechanically attached probes cause a temperature jump between the probe & sample. Reliable Seebeck measurements require elimination of the contact potentials Hall Effect – Edwin Hall (1879) A conductor/semi-conductor carrying current I is subjected to a magnetic field B at right angles, then in a plane mutually Perpendicular there develops a voltage known as Hall voltage Hall effect is observed in metals & semi-conductors Hall effect- Illustration Current I in X direction L to R Mag. Field B in Z direction Hall voltage VH in Y direction Hall effect due to deflection of Charge carriers in mag. Field VH = IB/qnd q- Electron charge 1.602 x10-19 coloumb n- No.of charge carriers d- Thickness of sheet nd= ns- Charge density Charge carriers per unit vol. ns = IB/ q*I VHI VH negative VH positive n-type semi conductor p-type semi conductor Hall effect- Illustration Hall effect RH – Hall coefficient RH =1/ ne n- No. of charge carriers per cm3 Hall effect measurement Hall voltage measurement Sample n-type Ge metal strip Hall voltage across terminal 3 Applied voltage measured across 2.1 & 2.2 or 2.3 ( up to 30 ma current) Knob 5 for adjusting off-set voltage ( emf when mag. Field is zero) Plugs 4 –Support; For applying current to heat the crystal Jacks 7- For thermocouple Magnetic field applied perpendicular to the metal strip

![Semiconductor Theory and LEDs []](http://s2.studylib.net/store/data/005344282_1-002e940341a06a118163153cc1e4e06f-300x300.png)