Solid-Liquid interface

advertisement

From Pattern Formation to

Phase Field Crystal Model

吳國安 (Kuo-An Wu)

清華大學物理系

Department of Physics

National Tsing Hua University

3/23/2011

Pattern Formation in Crystal Growth

by Wilson Bentley (The snowflake man), 1885

Pattern Formation in Crystal Growth

At the nanoscale (atomistic scale)

Liquid-Solid interfaces

Anisotropy ↔ Morphology

Atomistic details ↔ Anisotropy?

Hoyt, McMaster

Solid-Solid interfaces

Grain boundary

Atomistic details ↔ growth?

Al-Cu dendrite, Voorhees Lab

Northwestern University

Schuh, MIT

Atomistic details ↔ Continuum theory at the nanoscale

Pattern Formation in Macromolecules

Polyelectrolyte Gels

Hexagonal phase in solvent rich region

Hex (-)

Hexagonal phase in polymer rich region

Competition between Enthalpy, Entropy, Elastic Network Energy,

Electrostatic energy, … etc

Hex (+)

Pattern Formation in Biology

Lincoln Park Zoo

Chicago

Rural Area, Wisconsin

Pattern Formation in Biology

Nuclear Lamina (核纖層)~30-100nm

In animal cells, only composed of 2 types lamins

Lamin (核纖層蛋白) A/C

Lamin B1, B2

Bleb Formation in Breast Cancer Cell Nucleus

Goldman Lab, Northwestern University

Confocal Immunofluorescence of a normal cell nucleus

Goldman Lab, Northwestern University

Crystal Growth at the Nanoscale

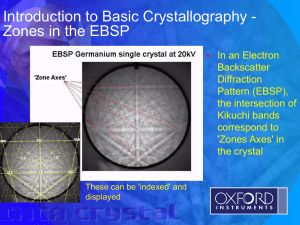

Solid-Liquid interface

Crystal growth from its

melt with interfacial

anisotropy

Solid-Fluid interface

under stress

Quantum dots

InAs/GaAs

Ng et al.,

Univ. of Manchester, UK

Solid-Solid interface

Grain boundaries

Schuh/MIT

Morphology vs. Anisotropy

tT D2T

LVn cD

T

TI TM

n

solid

nT liquid

V

TM

TrS n

L

nˆ

d 2

S ij

d i d j

Anisotropy of

Max(TI T ) Min(TrS )

Gibbs-Thomson condition

1/TrS

(Max ΔT)

Phase-field simulations

of solidification

What causes the anisotropy?

Crystal growth – Solid-Liquid interface

Basal Plane

Anisotropy vs. Crystal structures

3

17

4

4

2 2 2

nˆ o 1 1 ni 2 3 ni 66nx ny nz

5

7

i

i

0 uK eiK r

K

K K

K K

110

BCC

111

FCC

uK us

WHY?

fcc

uK 0

bcc

Ginzburg-Landau Theory

F (uk )

GL Theory for bcc-liquid interface

Free energy functional for a planar

solid-liquid interface with normal zˆ

a2 cij ui u j 0, K K a3 cijk ui u j uk 0, K K K

i

j

i

j

k

i, j

i , j ,k

n0 k BT

2

DF

dr

ui z

2

a4 cijkl ui u j uk ul 0, Ki K j Kk Kl b ci z

0 uK eiK r

i

,

j

,

k

,

l

i

K

Density Functional Theory of Freezing

DF dr r ln

a2

12

S K110

r

1

2 r 3 4 dr dr c r , r D r D r

dr

1

2

a3u110 0 a4u

1 2 1 2

0F a2u110

2110

c( K0 ) S ( K0 ) / S ( K0 )2

b 2c KDF

110

FS FL

,

ci

1 ˆ

K n zˆ

4

2

FS

0

u110

Liquid structure factor

S(K)

a3 and a4 are

determined u110

Liquid

by equilibrium conditions

K0

Solid

K (Å-1)

Bcc-liquid interface profile

For the crystal face z (110)

{110} is separated into three subsets

K1 10 , K 110

0

1

4

0

Kˆ zˆ 1

Kˆ zˆ

2

1

2

K110 , K 1 10

K101 , K10 1 , K 101 , K 101

Kˆ zˆ

K 011 , K 01 1 , K 0 11 , K 0 11

D F

0

u110

DF

0

u

1 10

D F

0

u101

2

zˆ

1

4

us

K101

K110

0

K110

zˆ

Anisotropic Density Profiles

z (1,1)

K1 10 , 10 , 01 , 0 1

2D Square Lattices

z (1, 0)

K1 10 , 10

z (3, 1)

K1 10 , 10

K 01 , 0 1

2

K 01 , 0 1

2

Symmetry breaks at interfaces → Anisotropy

Comparison with MD results

1

n( z )

Lx Ly

Lx Ly

dxdy (r )

0 0

0 uK eiK r

K

BCC Iron

n x 10-23

(cm-3)

Comparison with MD results

Anisotropy

4

100 110

100 110

(erg/cm2)

Fe

100

110

111

4 (%)

MD (MH(SA)2)

177.0(11)

173.5(11)

173.4(11)

1.0(0.6)

GL theory

144.26

145.59

137.57

1.02

Predict the correct ordering of

and weak anisotropy 1% for bcc crystals

Atomistic details (Crystal structures) matter!

Methodology for atomistic simulations

Molecular Dynamics (MD)

Mean field theory

Ginzburg-Landau theory

1

0

Rely on MD inputs

Average out atomistic details

Diffusive dynamics (ms)

Larger length scale (m)

Elasticity, defect structure, … etc?

Realistic physics

Resolve vibration modes (ps)

Methodology for atomistic simulations

Mean field theory

Phase field crystal (PFC)

Molecular Dynamics (MD)

Realistic physics

Resolve vibration modes (ps)

Average out vibration modes (ms)

Atomistic details – elasticity, crystalline planes,

dislocations, … etc.

Formulation - Phase Field Crystal

(001) plane of

bcc crystals

(100)

(110)

Swift & Hohenberg, PRA (1977)

2D Patterns – Rolls, Hexagons

Elder et al., PRL (2002)

Propose a conserved SH equation

The Free Energy Functional

Equation of Motion

Capillary Anisotropy?

Elasticity?

PFC Model – Phase Diagram

Conserved Dynamics

Phase diagram

K {110}

AK eiK r

Multi-scale Analysis

Seek the perturbative solution

Assumption – interface width is much larger

than lattice parameter

Maxwell construction

The solid-liquid coexistence region

A weak first-order freezing transition

(The multi-scale analysis of bcc-liquid

interfaces will be carried out around c)

Multi-scale Analysis – Amplitude equation

Small limit – diffuse interface

Multi-scale analysis

Ai0 Z

Equal chemical potential in both phases

One of twelve stationary amplitude equations

eiKi r

Order Parameter Profile Comparison

For the crystal face

z (110)

Determination of the PFC

model Parameter from density

functional theory of freezing

u110

0.0923 for Fe with

MH(SA)2 potential (MD)

Comparison with MD results

Anisotropy

100 110

4

100 110

(erg/cm2)

Fe

100

110

111

4 (%)

MD (MH(SA)2)

177.0(11)

173.5(11)

173.4(11)

1.0(0.6)

GL theory

144.26

141.35

137.57

1.02

PFC

144.14

140.67

135.76

1.22

Predict the correct ordering of

100 > 110 > 111

and weak anisotropy 1% for bcc crystals

What about Other Crystal Structures?

Phase diagram

K {110}

AK eiK r

y

(110)

x

11 1

1 11

z

(011)

200

GL theory of fcc-liquid

interfaces

(10 1)

2

2

F a2u111

a4u1411 b2u200

b4u204 0

The principal reciprocal lattice vectror

F a u a u a u

2

2 110

3

3 110

4

4 110

2

b

u

of fcc 31,111u1,200

1 cannot form triad

3

K ix 0

FCC-Liquid

BCC-Liquid

i 1

2

4

F a2u111

a4u111

F

F

u110

cannot form solid - liquid interfaces

FCC Model

The Two-mode

PFC modelfcc model

Twin Boundary

2

(1,1,1)

2

a

(2, 0, 0)

a

2

K 02

1

1,1,1 1

3

2

K12

S (K )

1

4

2,

0,

0

3

3

Phase Diagram

K

FCC Polycrystal

Design Desired Lattices

Elasticity

Example: Square Lattices

Multi-mode model

Single-mode model

Dictate interaction angle

(lattice symmtry)

Grain Boundary

Grain boundary is composed of

dislocations

Geometric arrangement of crystals

determines dislocation distribution

Distinct evolution for low and high

angle grain boundary

b

D

D

b : magnitude of Burgers vector

D : misorientation

D

Symmetric tilt planar grain boundary in gold

by STEM

GB sliding and coupling

GB Coupling – Low Angle GB

/2

GB Sliding – High Angle GB

/2

Dt

Well described by

continuum theory

Dn

Sutton & Balluffi, Interfaces in Crystalline Materials, 1995

Large Misorientations

20

Curvature driven motion

G.B. sliding (fixed misorientation)

remains constant

Well described by classical continuum theory

Small Orientations

Theory that only considers

DF 2 R GB

Misorientation decreases?

Atoms at the center of the circular grain

5

Misorientation increases!

Small Misorientations

G.B. coupling

For symmetric tilt boundaries

Misorientation increases

GB energy increases

Misorientation-dependent mobility:

(Taylor & Cahn)

Intermediate Misorientations – cont.

10

v ~ C / rm

Area r C (1 at )

2

m 2.3

2

m1

Intermediate Misorientations

Faceted–Defaceted Transition

10

Frank-Bilby formula

Tangential motion of dislocations

Annihilation of dislocations

Intermediate Misorientations – cont.

Spacing d1 is a function of GB normal

2

nˆ

b1 b2

r

d1

N1 nˆ b2 b1 b2

Instability of tangential motion occurs when

R

3 sin F / 6

3

G F

2 cos 2 F / 6 2

G F

0

F

/3

Dd

Three-Grain System

5.2o

Grain Rotation?

GB wiggles

0o

5.2o

Grain Rotation

5.2o

0o

5.2o

0o

5.2o

Grain Translation

5.2º

GB

Wriggles

0º

-5.2º

Dihedral angle

follows Frank’s formula

not the Herring relation

Self-Assembled Quantum Dots

Quantum-dot LEDs

Lee et al., Lawrence Livermore National Laboratory

Other Applications

- Tunable QD Laser

- Quantum Computing

- Telecommunication

- and more

Quantum dots

InAs/GaAs

Ng et al.,

Univ. of Manchester, UK

Stress Induced Instability – Asaro-Tiller-Grinfeld Instability

DU

A

Cullis et al. (1992): 40 nm

Linear perturbation

calculation

DU

2 ˆ2

2

thick

h kSi

0.79

EGe

E , on

,0.21

k (001) Si

A

substrate - Grown at 1023 K

2

c (Defect-free

2

10 growth)

100 nm

kc

E

hˆ exp ik x x ik y y

kc

zˆ

h

Film

Misfit Parameter

a as

f

as

af

Substrate

0

Schematic plot from Voorhees and Johnson

Solid State Physics, 59

as

xˆ

k

Later Stage Evolution - Cusp Formation - Dislocations

High stress concentration at the tip

Si0.5Ge0.5/Si(001)

Jesson et al., Z-Contrast,

Oak Ridge Natl. Lab.,

Phys. Rev. Lett. 1993

Various sizes

Simulation Parameters

0

The PFC model

F dr

1

2

F

2

t

2

2

1

Ly

8

1 4

4

Hexagonal

Phase

Simulation parameters

0.10

Ly

Lx

Ny

Nx

Constant

Phase

o

a 2 A

3

2

N x 448 1280

N y 2048

o

Ly 1900 A

o

Lx 480 1360 A

# of atoms 15, 000

40, 000

7

Ly

8

Constant

Phase

(1+xx)Lx

Nonlinear Steady State for a Smaller k

k

Quantitative Comparison of Strain Fields

xx 1%

F dr

2

1

2

2

1 4 , F

4

t

ˆxx , ˆyy

ˆxx

ˆyy

y

Correct elastic fields

Elastic fields relax much

faster than the density field

AK eiK r

K

: conserved quantity

AK : non-conserved quantity

Critical Wavenumber vs Strain

Linear perturbation theory

- Sharp Interface

- Homogeneous Materials

kc

Classical Elasticity Theory E xx

PFC simulations

Nonlinear Elasticity

PFC simulations

2E xx2

E : Young's modulus

: Surface energy

W

c

xx2

Linear Elasticity

kc ~ xx2 for small strains

Nonlinear elasticity modifies length scale

1

Xie et al., Si0.5Ge0.5 films, PRL

PFC modeling of nonlinear elasticity

xx ~ 0

Liquid

Inhomogeneous materials

nonlinear elasticity

Solid

E ( xx )

xx 2%

Finite Interface Thickness Effect

Eint erface Esolid

Liquid, E=0

Upper bounds

c~1/2·xx-2

W~-1/2

E(x,y)

Solid, E=Eo

Interface thickness is no longer negligible at the nanoscale

Finite interface thickness W

Elastic constants vary smoothly

across the Interface region

Nonlinear Evolution for k ~ km

k

3D Island – BCC Systems

And More …

VLS nanowires

Nano-particles with defects

And More …

Pattern Formation - Examples

Agular et al, Oxford University

Ice Crystal

North Pole Hexagon on Saturn

Rock Formation in Ireland

Honeycomb

Graphene

Collaborators

Alain Karma

Northeatsern University

Mathis Plapp

Laboratoire de Physique de la Matière Condensée

Ecole Polytechnique

Peter W. Voorhees

Northwestsern University