multi-environment - Wolfram Library Archive

advertisement

Automatic Generation of Numerical Codes

Jože Korelc

University of Ljubljana, Slovenia

www.fgg.uni-lj.si/Symech/

Solution procedure required by modern engineering

Multi-field

Multi-scale

Multi-body

F

F

M5

Multi-phase

Multi-objective

0.47e1

0.10

0.16

0.22

0.28

0.34

0.40

DeformedMeshX

M

a

x

.

0.1277e1

Min.

0.465

AceGen

2 J. KORELC, UNIVERSITY OF LJUBLJANA

Hybrid system for FE code generation and FE analysis

Mathematica

AceGen input

FE environment

dependend user subroutine

interface

AceGen

code generator

user subroutines

• tangent, residual

•post-processing

•....

element source file

C

FE

CDriver

environment • C code

Mathematica

Driver

•Math link

Optimisation

environment

3 J. KORELC, UNIVERSITY OF LJUBLJANA

Mathematica

Computational

Templates

package

suplementary subroutines

• initialization

•numerical integration

FORTRAN

MDriver

• full symbolic

cappabilities

• Mathematica

Inverse

ELFEN

FEAP

ABAQUS

Concepts of AceGen code generator

simultaneous optimization of expressions and introduction of intermediate

variables,

expression optimisation based on heuristic procedures,

generation of characteristic formulae,

the whole program structure can be generated,

automatic differentiation technique (forward and backward mode),

multi-language code generation (FORTRAN, C/C++, Mathematica language),

multi-environment code generation (automatic interface to numerical environments)

methods for exploring of generated formulae and run time debugging of the

generated programs

•

•

special procedures are needed for non-local (explicit form of the expressions is lost)

AD inside a single subroutine

4 J. KORELC, UNIVERSITY OF LJUBLJANA

Multi-language code generation with AceGen

1. Mathematical description

@

D

@

8

@

D

@

D

<

D

8<8@@

D

@

D

<

@

@

D

DD

9 IM

=

@

D

@

D

@

D

2. Symbolic description in AceGen

SMSInitialize "test", Language - > "C++ "

SMSModule "Test", u1$$ 3 , x$$, L$$, g$$ 3

x, L Ł SMSReal x$$ , SMSReal L$$ ;

u N i ui

ui Ł Array SMSReal u$$ #

x

x x

x

N { ,1 , (1 )}

L

L L

L

2

f u

3. Automatically generated code

"Fortran"

SUBROUTINE Test(v,u1,x,L,g)

REAL*8 v(500),u1(3),x,L,g(3)

v(6)=x/L

v(7)=1d0 - v(6)

v(8)=v(6)*v(7)

v(12)=2d0*(u(1)*v(6) +

- u(2)*v(7) + u(3)*v(8))

g(1)=v(12)*v(6)

g(2)=v(12)*v(7)

g(3)=v(12)*v(8)

END

5 J. KORELC, UNIVERSITY OF LJUBLJANA

"C++"

x

x x

,1,

L

L L

u Ł Ni . ui;

Ni Ł

1-

x

L

;

&, 3 ;

;

f Ł u2 ;

g Ł SMSD f, ui ;

SMSExport g, g$$ ;

SMSWrite ;

void Test(double v[501],

double u1[3],double *x,

double *L,double g[3])

{

v[6]=*x/*L;

v[7]=1e0 - v[6];

v[8]=v[6]*v[7];

v[12]=2e0*(u[0]*v[6] +

u[1]*v[7]+ u[2]*v[8]);

g[0]=v[12]*v[6];

g[1]=v[12]*v[7];

g[2]=v[12]*v[8];

};

"Mathematica"

Test[]:=Module[{},

$VV[6]=x$$/L$$;

$VV[7]=1 - $VV[6];

$VV[8]=$VV[6]*$VV[7];

$VV[12]=2*(u$$[1]*$VV[6] +

u$$[2]*$VV[7]+u$$[3]*$VV[8]);

g$$[1]=$VV[6]*$VV[12];

g$$[2]=$VV[7]*$VV[12];

g$$[3]=$VV[8]*$VV[12];

]

MDriver

Multi-environment code generation

CDriver

Suplementary

routines

user

subroutines

6 J. KORELC, UNIVERSITY OF LJUBLJANA

Open problems

Interactions:

symbolic system - simultaneous simplification procedure

symbolic system - automatic differentiation

symbolic system - simultaneous generation of program structure

automatic differentiation - simultaneous generation of program

structure

Verification & validation of generated codes:

Are the equations solved correctly?

Are the righ equations solved?

Interactive debugging of automatically generated numerical

codes

7 J. KORELC, UNIVERSITY OF LJUBLJANA

Symbolic system - simultaneous simplification

• Simultaneous stochastic optimisation procedure (Korelc 1997)

Additional operators

Auxiliary variables have standardized form $V[i, j],

where i is an index of auxiliary

variable and j is an instance of the i-th auxiliary variable.

8 J. KORELC, UNIVERSITY OF LJUBLJANA

Optimisation of an matrix - common sub expressions

Vector of 3 new auxiliary variables:

1

2

v

3

1

2

E

I v

L2

v

L

L 2 3

Original matrix

(input for code generator):

12 EI

L3

6 EI

2

L

K0 12 EI

L3

6 EI

2

L

6 EI

2

L

4 EI

L

6 EI

L2

2 EI

L

12 EI

L3

6 EI

L2

12 EI

L3

6 EI

L2

6 EI

2

L

2 EI

L

6 EI

L2

4 EI

L

internal

data base

Code

generator

Mathematica

v2 v1 v2

v1

v3

v

v

v

2

3

2

2

KSv1 v2 v1 v2

v

3

v

v2 v3

2

2

Result is simplified matrix, expressed with the

new auxiliary variables

9 J. KORELC, UNIVERSITY OF LJUBLJANA

Symbolic system - flow control

• "If" construct

SMSIf x

0 ;

$V[i,1]

2

f x ;

SMSElse

;

f Sin x ;

$V[i,2]

SMSEndIf f ;

fictive variable

$V[i,3]

• "Do" construct

f 1;

SMSDo i, 1, n, 1, f ;

f f

i

x;

SMSEndDo f ;

10 J. KORELC, UNIVERSITY OF LJUBLJANA

Symbolic system - automatic differentiation

• Automatic differentiation technique (AD):

– differentiation of the whole program

– automatic differentiation tool generates a program code for the derivative from a

program code for the basic function

• Reverse mode / Forward mode

• Enhancements with respect to the standard AD technique:

– AD procedure can be initiated at any time and at any point of

derivation of the formulas and as many times as required

– AD as code-to-code translator has to be replaced by the method that

consistently extends current code rather than produce a new one

– the results of all previous uses of AD have to be accounted for when AD is

used several times inside the same subroutine

– The user has to be able to use all the capabilities of the symbolic system on

the final and intermediate results of AD procedure.

11 J. KORELC, UNIVERSITY OF LJUBLJANA

AD exceptions

The basic situations that have to be considered are:

•

there exists implicit dependency between variables

that has to be considered for the differentiation

•

there exists explicit dependency between variables

that has to be neglected for the differentiation

•

the evaluation of the derivative code would lead to

numerical errors

Example:

sin( 2 2 )

0

f :

2

Lim sin( 2 ) 0

0

sin( 2 2 )

) 0

(

f

:

sin( 2 2 )

Lim

(

) 0

0

Exceptions handling function:

SMSFreeze exp, Dependency

12 J. KORELC, UNIVERSITY OF LJUBLJANA

p1 ,

exp

, p2,

p1

exp

, ..., pn ,

p2

exp

pn

Example: limit load optimisation of cantilever beam

• Task: find the shape (h(x)) of cantilever beam that has:

– minimal volume

– given ultimate load

– ideal elasto-plastic material

• Properties of the problem:

– transient coupled problem

– gradient based optimisation

Response

direct analysis

qu ultimate load

u

0.180e3

0.160e3

0.140e3

0.120e3

0.100e3

0.800e2

0.600e2

0.400e2

0.201e2

A

Misses

Max.

h(x)

x

0.2000e3

vA

optimal

solution

Min.

0.1225

AceGen

optimal shape?

13 J. KORELC, UNIVERSITY OF LJUBLJANA

b

b

v

Formulation of the problem

• Three finite elemnts are needed to describe the problem:

– 2D elasto plastic element

– line load element

– prescribed displacement constrain element

a {u, }

u displacements , load factor

Ψ

Ψ u

Ψ

obt. el.

el.-plast.

Ψu Ψu Ψu

Ψu

el.-plast.

Ψu

obt. el.

standard ideal elasto-plastic formulation equations

q. u d load element equations

Newton-Raphson scheme to

solve direct problem

K uu K u u Ψu

K

Ψ

K

u

Ψ v A v v p prescribed displacement constrain element equations

• Objective function

min 0 ; 0 ( u ) 2 Volume penaltyconstrain h ( x ) 0

u prescribed limit load factor

calculated limit load factor

14 J. KORELC, UNIVERSITY OF LJUBLJANA

k

Solution

• Analytical solution can be obtained by assuming:

– Bernoully beam theory

– in optimal case every material point is in plastic condition

2 qu

M ( x)

y h( x )

x

Wpl ( x)

b y

y ... yield stress

• Optimal finite element solution for given load

0.174e3

0.149e3

0.124e3

0.997e2

0.746e2

0.496e2

Misses

Max.

0.2000e3

Min.

0.2456e2

AceGen

h(0) 20.41

analytical solution

h(0) 21.2

numerical solution

15 J. KORELC, UNIVERSITY OF LJUBLJANA

Typical examples: Multi - field problems

• unduction heating

•

T. Šuštar , C3M - Ljubljana, Slovenia

Magnetic

16 J. KORELC, UNIVERSITY OF LJUBLJANA

Thermal

Mechanical

Typical examples: Multi-scale problems

S. Stupkiewicz, IPPT, Warsaw, Poland

MICRO - 3D surface roughness

MACRO - elastic properties of contact surface

MACRO - lubricant flow in contact surface

17 J. KORELC, UNIVERSITY OF LJUBLJANA

MACRO - thermal properties of contact surface

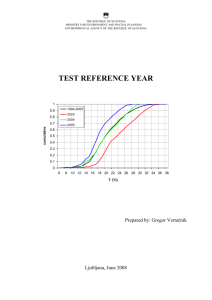

Typical examples: structural analysis

• Sensitivity analysis of single-storey steel building

• four node shell elements and large displacement truss elements

A

Sensitivity

18

16

Analitic (elastic)

14

Finite differeces (elastic)

12

Analitic (plastic)

10

Finite differeces (plastic)

8

6

4

2

0

0

18 J. KORELC, UNIVERSITY OF LJUBLJANA

10

20

30

Roof angle (deg)

40

50

Typical examples: Simulation of technological proces

J. Lengiewicz, IPPT, Warsaw, Poland

Two phase forging

19 J. KORELC, UNIVERSITY OF LJUBLJANA

Conclusions

• Hybrid system presented is a powerfull tool for solving

large-scale engineering problems

• System can be dowloaded from www.fgg.uni-

lj.si/Symech/

20 J. KORELC, UNIVERSITY OF LJUBLJANA