Introduction

Introduction to System Modeling and

Control

Introduction

Basic Definitions

Different Model Types

System Identification

Neural Network Modeling

Mathematical Modeling (MM)

A mathematical model represent a physical system in terms of mathematical equations

It is derived based on physical laws

(e.g.,Newton’s law, Hooke’s, circuit laws, etc.) in combination with experimental data.

It quantifies the essential features and behavior of a physical system or process.

It may be used for prediction, design modification and control.

Engineering Modeling Process

Theory

Data f c

v

T m

dv dt

v

x

bv f

Numerical

Solution

Engineering

System

Example: Automobile

• Engine Design and Control

• Heat & Vibration Analysis

• Structural Analysis

Math. Model

Model

Reduction

Control

Design

Solution

Data

Graphical

Visualization/Animation

Definition of System

System: An aggregation or assemblage of things so combined by man or nature to form an integral and complex whole.

From engineering point of view, a system is defined as an interconnection of many components or functional units act together to perform a certain objective, e.g., automobile, machine tool, robot, aircraft, etc.

System Variables

Every system is associated with 3 variables: u y

System x

Input variables (u) originate outside the system and are not affected by what happens in the system

State variables (x) constitute a minimum set of system variables necessary to describe completely the state of the system at any given time.

Output variables (y) are a subset or a functional combination of state variables, which one is interested to monitor or regulate.

Mathematical Model Types

discrete-event

Lumped-parameter distributed

Most General x

f ( x , u , y

h ( x , u , t t )

) y

( n )

Input-Output Model f ( y

( n

1 )

, , , y , u

( n )

, , , u , t )

Linear-Time invariant (LTI) y

Ax

Cx

Bu

Du y

( n ) a

1 y

( n

1 )

LTI Input-Output Model

a n

1

y

a n y

b

0 u

( n )

b n

1 u b n u

Transfer Function Model

Y ( s )

G ( s ) U ( s )

Discrete-time model: y

(

( i ) t )

( t

) x

( t y (

t

1 )

i )

Example: Accelerometer (Text 6.6.1)

Consider the mass-spring-damper (may be used as accelerometer or seismograph) system shown below:

Free-Body-Diagram x f s f s x

M

M f d f d f s

( y ): position dependent spring force, y=u-x f d

( y ): velocity dependent spring force

Newton’s 2nd law M x

M

Linearizaed model:

f d

( )

f s

( y )

M y

b y

ky

M u

u

Example II: Delay Feedback

Consider the digital system shown below: y u

Delay z -1

Input-Output Eq.: y ( k )

y ( k

1 )

u ( k

1 )

Equivalent to an integrator: y ( k )

j

1 k

0 u ( j )

Transfer Function

Transfer Function is the algebraic input-output relationship of a linear time-invariant system in the s (or z) domain

U G Y

Example: Accelerometer System m y

b

ky

G ( s )

Y ( s )

U ( s )

ms 2 ms 2

bs

k

, s

d dt

Example: Digital Integrator y ( k )

y ( k

1 )

u ( k

1 )

G

Y ( z ) u ( z )

1 z

1

z

1

, z

Forward shift

Comments on TF

Transfer function is a property of the system independent from input-output signal

It is an algebraic representation of differential equations

Systems from different disciplines (e.g., mechanical and electrical) may have the same transfer function

Acceleromter Transfer Function

Accelerometer Model: M y

b y

ky

M u

Transfer Function: Y/A=1/(s 2 +2 n s+ n

2 )

n

=(k/m) 1/2 , =b/2 n

Natural Frequency n

, damping factor

Model can be used to evaluate the sensitivity of the accelerometer

Impulse Response

Frequency Response

Impulse Response

Frequency Response

Bode Diagrams

From: U(1)

40

20

0

-20

-40

-60

0

-50

-100

-150

-200

10

-1

10

0

Frequency (rad/sec)

/ n

10

1

Mixed Systems

Most systems in mechatronics are of the mixed type, e.g., electromechanical, hydromechanical, etc

Each subsystem within a mixed system can be modeled as single discipline system first

Power transformation among various subsystems are used to integrate them into the entire system

Overall mathematical model may be assembled into a system of equations, or a transfer function

Electro-Mechanical Example

Input: voltage u

Output: Angular velocity

u

R a i a

L a

B dc

J

Elecrical Subsystem (loop method): u

R a i a

L a di a dt

e b

, e b

back emf voltage

Mechanical Subsystem T motor

J

B

Electro-Mechanical Example

Power Transformation:

Torque-Current: T motor

K t i a

Voltage-Speed: e b

K b

u

R a i a

L a dc

B where K t

: torque constant, K b ideal motor K t

K b

: velocity constant For an

Combing previous equations results in the following mathematical model:

L a

J di a

dt

B

R a i a

K t

i a

K b

0

u

Brushless D.C. Motor

A brushless PMSM has a wound stator, a PM rotor assembly and a position sensor.

The combination of inner

PM rotor and outer windings offers the advantages of

low rotor inertia

efficient heat dissipation, and reduction of the motor size.

dq-Coordinates

c q b d

e

e

=p

+

0

Electrical angle a offset

Number of poles/2

Mathematical Model

di d dt di q dt

R

L

R i q

L i d

p

m i q

p

m i d

1 v d

L

K e

m

L

1 v q

L

Where p=number of poles/2, K e

=back emf constant

J m

T e

K t i q

System identification

Experimental determination of system model.

There are two methods of system identification:

Parametric Identification: The input-output model coefficients are estimated to “fit” the input-output data.

Frequency-Domain (non-parametric): The

Bode diagram [ G ( j ) vs. in log-log scale] is estimated directly form the input-output data.

The input can either be a sweeping sinusoidal or random signal.

Electro-Mechanical Example

Transfer Function, L a

=0:

Ω(s)

U(s) Js

B

K t

R a

K t

K

b

R a

Ts k

1 u t

12 ku

10

8 k =10, T =0.1

2

0

0

6

4 u

R a i a

L a

0.1

T

0.2

Time (secs)

0.3

B

K t

0.4

0.5

Comments on First Order

Identification

Graphical method is

difficult to optimize with noisy data and multiple data sets only applicable to low order systems difficult to automate

Least Squares Estimation

Given a linear system with uniformly sampled input output data, (u(k),y(k)), then y ( k )

a

1 y ( k

1 )

a n y ( k

n )

b

1 u ( k

1 )

b n u ( k

n )

noise

Least squares curve-fitting technique may be used to estimate the coefficients of the above model called ARMA (Auto Regressive

Moving Average) model.

Frequency-Domain Identification

Method I (Sweeping Sinusoidal):

A i system f t>>0

A o

Magnitude

A

0

A i

db

,

Method II (Random Input):

Phase

system

Transfer function is determined by analyzing the spectrum of the input and output

Photo Receptor Drive Test Fixture

Experimental Bode Plot

System Models

180

90

0

90

180

0.1

25

0

25

50

75

0.1

1

1 low order

10

Frequency (Hz)

10

Frequency (Hz)

100

100 high order

1 10

3

1 10

3

Nonlinear System Modeling

& Control

Neural Network Approach

Introduction

Real world nonlinear systems often difficult to characterize by first principle modeling

First principle models are often suitable for control design

Modeling often accomplished with inputoutput maps of experimental data from the system

Neural networks provide a powerful tool for data-driven modeling of nonlinear systems

Input-Output (NARMA) Model

u z -1 z -1 z -1 g z -1 z -1 z -1 y y [ k ]

g ( y [ k

m ],..., y [ k

1 ], u [ k

m ],..., u [ k

1 ])

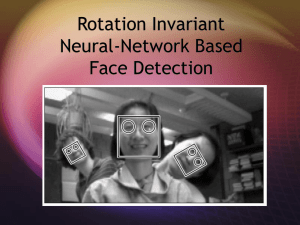

What is a Neural Network?

Artificial Neural Networks (ANN) are massively parallel computational machines

(program or hardware) patterned after biological neural nets.

ANN’s are used in a wide array of applications requiring reasoning/information processing including

pattern recognition/classification monitoring/diagnostics system identification & control

forecasting

optimization

Advantages and

Disadvantages of ANN’s

Advantages:

Learning from

Parallel architecture

Adaptability

Fault tolerance and redundancy

Disadvantages:

Hard to design

Unpredictable behavior

Slow Training

“Curse” of dimensionality

Biological Neural Nets

A neuron is a building block of biological networks

A single cell neuron consists of the cell body

(soma), dendrites, and axon.

The dendrites receive signals from axons of other neurons.

The pathway between neurons is synapse with variable strength

Artificial Neural Networks

They are used to learn a given inputoutput relationship from input-output data (exemplars).

The neural network type depends primarily on its activation function

Most popular ANNs:

Sigmoidal Multilayer Networks

Radial basis function

NLPN (Sadegh et al 1998,2010)

Multilayer Perceptron

MLP is used to learn, store, and produce input output relationships x

1 x

2

y

i w i

(

j x j v ij

) y function

The activation function (x) is a suitable nonlinear function:

Sigmidal: (x)=tanh(x) activation

Gaussian: (x)=e -x2 weights

Triangualr (to be described later)

Sigmoidal and Gaussian

Activation Functions

0.5

0.4

0.3

0.2

0.1

0

-5

1

0.9

0.8

0.7

0.6

-4 -3 gaussian

-2 -1 x

0 1 2 sigmoid

3 4 5

Multilayer Netwoks

y x

W

0

W p

W k,ij

: Weight from node i in layer k-1 to node j in layer k y

W

T p

σ

W

T p

1

σ

σ

W

T

1

σ

W

T

0 x

Universal Approximation

Theorem (UAT)

A single hidden layer perceptron network with a sufficiently large number of neurons can approximate any continuous function arbitrarily

close.

Comments:

The UAT does not say how large the network should be

Optimal design and training may be difficult

Training

Objective: Given a set of training inputoutput data (x,y t

) FIND the network weights that minimize the expected error

L

E ( y

y t

2

)

Steepest Descent Method: Adjust weights in the direction of steepest descent of L to make dL as negative as possible.

dL

E ( e

T d y )

0 , e

y

y t

Neural Network Approximation of

NARMA Model

u[k-1] y[k-m] y

Question: Is an arbitrary neural network model consistent with a physical system (i.e., one that has an internal realization)?

u

State-Space Model

system

States: x

1

,…,x n x [ k

1 ]

f ( x [ k ], u [ k ]) y [ k ]

h ( x [ k ]) y

A Class of Observable State

Space Realizable Models

Consider the input-output model: y [ k ]

g ( y [ k

m ],..., y [ k

1 ], u [ k

m ],..., u [ k

1 ])

When does the input-output model have a state-space realization? x [ k

1 ]

f ( x [ k ], u [ k ]) y [ k ]

h ( x [ k ])

Comments on State Realization of

Input-Output Model

A Generic input-Output Model does not necessarily have a state-space realization

(Sadegh 2001, IEEE Trans. On Auto. Control)

There are necessary and sufficient conditions for realizability

Once these conditions are satisfied the statespace model may be symbolically or computationally constructed

A general class of input-Output Models may be constructed that is guaranteed to admit a state-space realization

Fluid Power Application

INTRODUCTION

APPLICATIONS:

Robotics

Manufacturing

Automobile industry

Hydraulics

EXAMPLE:

EHPV control

(electro-hydraulic poppet valve)

Highly nonlinear

Time varying characteristics

Control schemes needed to open two or more valves simultaneously

Motivation

The valve opening is controlled by means of the solenoid input current

The standard approach is to calibrate of the current-opening relationship for each valve

Manual calibration is time consuming and inefficient

Research Goals

Precisely control the conductivity of each valve using a nominal input-output relationship.

Auto-calibrate the input-output relationship

Use the auto-calibration for precise control without requiring the exact input-output relationship

INTRODUCTION

EXAMPLE:

Several EHPV’s were used to control the hydraulic piston

Each EHPV is supplied with its own learning controller

Learning Controller employs a Neural Network (NLPN) in the feedback

Satisfactory results for single EHPV used for pressure control

Control Design

Nonlinear system (‘lifted’ to a square system) x k

n

F

x k

, u k

Feedback Control Law

u

ˆ

( x d

, x d

)

K p

ˆ ( x d

x d

, x d

)

( x

x d

)

ˆ ( x d

, x d

) is the neural network output

The neural network controller is directly on the time history of the tracking error trained based

Learning Control Block Diagram