III-Advanced Lithography

advertisement

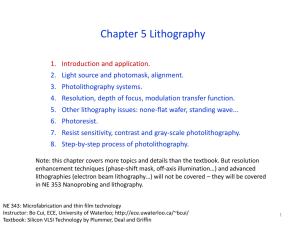

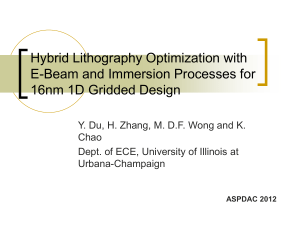

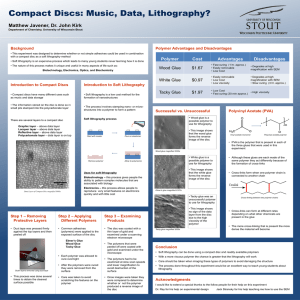

Lithography-Part 2 Dr. Marc Madou, UCI, Fall 2012 Class 6 Content Photolithography limits Next Generation Lithography (NGL) – – – – EUV X-Ray Lithography E-beam Ion-beam Other proposed lithography scenarios of the future Photolithography Three ways to improve resolution Wmin (also R is used in the text) We will derive this expression and analyze all the different means of reducing Wmin(also R) Photolithography-NA Photolithography-NA Photolithography-Diffraction At smaller dimensions, diffraction effects dominate If the aperture is on the order of l, the light spreads out after passing through the aperture. (The smaller the aperture, the more it spreads out.) If we want to image the aperture on an image plane (resist), we can collect the light using a lens and focus it on the image plane. But the finite diameter of the lens means some information is lost (higher spatial frequency components). Photolithography-Diffraction Image formed by a small circular aperture (Airy disk) as an example Image by a point source forms a circle with diameter 1.22lf/d *surrounded by diffraction rings (airy pattern) Diffraction is usually described in terms of two limiting cases – Fresnel diffraction - near field. – Fraunhofer diffraction - far field. *If one considers diffraction through a circular aperture, then the calculation involves a Bessel function -- 1.220 is approximately the first zero of the Bessel function of the first kind, of order one (i.e. J1), divided by π. Photolithography-Diffraction Photolithography-Diffraction Rayleigh suggested that a reasonable criterion for resolution (R = distance between A and B) is that the central maximum of one point source lies at the first minimum of the Airy pattern of the other point (R = diameter of circle) The numerical aperture (NA) of a lens represents the ability of the lens to collect diffracted light and is given by NA = n sin a in this expression n is the index of refraction of the medium surrounding the lens and a is the acceptance angle of the lens ( n = 1 for air) When a is small, 2sin a =d/f Photolithography-Diffraction In the latter expression k1 is an experimental parameter and depends on resist properties and the lithography system ( 0.6-0.8) You may remember that, for a plane wave incident on a grating of period d, the angles q at which the intensity maxima in the image occur are given by: sin q = N l/d, where N= 0,1,2,…. (Bragg’s equation)---difference is slits vs holes Photolithography-Diffraction The angle q in the figure on the top right is the maximum angle for which diffracted light from the mask will be collected for imaging by the lens. With sin q = N l/d only those values of N for which the term on the right is less than sin q are allowed. Thus, as the period d gets smaller (l/d gets larger), N gets smaller (i.e. lower number of diffracted orders gets through). The middle figure on the right shows the spread of the diffracted orders for a decrease in relative slit width (b). Because of this spreading effect, fewer diffracted orders form the image. This means that information about the pattern is being lost. Photolithography-Diffraction The figure on the right shows the effect of including increasing numbers of diffracted orders on the image of a slit of width w. You can think of the aperture as truncating these diffracted orders at some small number. The value of sin a for an optical system is the numerical aperture, or NA. If the value of the NA is small for a system, fewer orders will be imaged, and the grating may not be resolved. It has been shown that the depth of focus, DOF, or the range of focus for which a feature can be resolved, is given by: DOF = ±k2 l/(NA)2 The R and DOF equations sum up all of the problems and the promise of optical lithography using projection tools: The way to increase resolution is to decrease the wavelength at which the machine can operate, and to increase the numerical aperture of the lens. However, both of these options have the effect of decreasing the depth of focus. Photolithography-DOF The defocus tolerance (DOF) Much bigger issue in miniaturization science than in ICs A small aperture was used to ensure the foreground stones were as sharp as the ones in the distance. What you need here is a use a telephoto lens at its widest aperture. Photolithography-DOF Photolithography- MTF Another useful concept is the modulation transfer function or MTF MTF is the ratio between image intensity modulation over the object intensity modulation This parameter qualifies the capability of an optical system Photolithography- MTF Function describes contrast as a function of size of features on the mask Generally, MTF needs to be > 0.5 for the resist to resolve features Photolithography- Coherence Only point sources are completely coherent (light waves impinging perpendicular on the mask) In reality, light sources do have a finite size resulting in partially coherent light The definition for coherence is S= NAc/NAo or also S =s/d (see Figure) MTF depends on S : An S of 0.5-0.6 is typical design tradeoff Photolithography- Coherence Photolithography-OAI and Kohler “Off-axis illumination” also allows some of the higher order diffracted light to be captured and hence can improve resolution (by decreasing k1). Photolithography-OAI and Kohler Kohler illumination systems focus the light at the entrance pupil of the objective lens. This “captures” diffracted light equally well from all positions on the mask. This method improves the resolution by bringing k1 down. Photolithography- OPC Optical Proximity Correction (OPC) can be used to compensate somewhat for diffraction effects. Sharp features are lost because higher spatial frequencies are lost due to diffraction. These effects can be calculated and can be compensated for. This improves the resolution by decreasing k1. Photolithography-Phase Shift Masks Extends resolution capability of current optical lithography Takes advantage of the wave nature of light PSM changes the phase of light by 180° in adjacent patterns leading to destructive interference rather than constructive interference Improves MTF of aerial image on wafer. Making k1 smaller. Photolithography- Phase Shift Masks A number of companies now provide OPC and phase shifting software services. The advanced masks which these make possible allow sharper resist images and/or smaller feature sizes for a given exposure system. Photolithography-l Photolithography-NA At the same time that exposure wavelengths have been reduced, improvements in lens design has led to improvements in the NA of exposure systems lens, see figure . In the mid eighties an NA value of approximately 0.4 was typical, today 248nm exposure systems are available with an NA greater than 0.8. The physical limit to NA for exposure systems using air as a medium between the lens and the wafer is 1, the practical limit is somewhere around 0.9, with recent reports suggesting that an NA as high as 0.93 may be possible for ArF systems in the future . Photolithography- k1 The third element in the Rayleigh equation is k1. k1 is a complex factor of several variables in the photolithography process such as the quality of the photoresist and the use of resolution enhancement techniques such as phase shift masks, off-axis illumination (OAI) and optical proximity correction (OPC). While exposure wavelengths have been falling and NA rising, k1 has been falling as well, see figure . The practical lower limit for k1 is thought to be about 0.25. Photolithography-Immersion Litho From the discussion to this point, the resolution limit for 193nm exposure systems may be calculated using the Rayleigh equation with, l = 193nm, NA = 0.93 and k1 = 0.25 or From the above a highly optimized ArF exposure system has an absolute maximum resolution of 52nm, sufficient for 65nm linewidths forecast in 2005, but not capable of meeting the 45nm linewidths forecast in 2007. The technical challenges with 157nm and shorter wavelength exposure systems make any technique that can improve the resolution of the 193nm exposure systems and delay the need to move to shorter wavelengths an important development. Photolithography-Immersion litho NA is determined by the acceptance angle of the lens and the index of refraction of the medium surrounding the lens. The physical limit for an air based system is clear, but what if a medium with a higher index of refraction is substituted for air? Microscopy has for years used oil between the lens and the sample being viewed for resolution enhancement and it is somewhat surprising that the semiconductor industry has taken this long to seriously consider the merits of replacing air with an alternative. Photolithography-Immersion Litho The medium between the lens and the wafer being exposed needs to have an index of refraction >1, have low optical absorption at 193nm, be compatible with photoresist and the lens material, be uniform and non-contaminating. Surprisingly, ultrapure water may meet all of these requirements. Water has an index of refraction n = 1.47, absorption of <5% at working distances of up to 6mm, is compatible with photoresist and lens and in it’s ultrapure form is noncontaminating. Photolithography-Immersion Litho Quiz: what does immersion litho do to DOF? Next Generation Lithography (NGL) Next Generation Lithography (NGL) Next Generation Lithography : EUV Uses very short 13.4 nm light All reflective optics (at this wavelength all materials absorb!) Uses reduction optics (4 X) Step and scan printing Optical tricks seen before all apply: off axis illumination (OAI), phase shift masks and OPC Vacuum operation Laser plasma source Very expensive system Next Generation Lithography : EUV Mask fabrication is the most difficult task Next Generation Lithography: E-Beam Diffraction is not a limitation on resolution (l < 1 Å for 10-50 keV electrons) oResolution depends on electron scattering and beam optics the size of the beam, can reach ~ 5 nm oTwo modes of operation: oDirect writing with narrow beam oElectron projection lithography using a mask :EPL oIssues: oThroughput of direct writing is very low : research tool or low pattern density manufacturing oProjection stepper (EPL) is in development stage only (primarily by Nikon). oMask making is the biggest challenge for the projection method oBack-scattering and second electron result in proximity effect –reduce resolution with dense patterns there is also the proximity effect -6 –10-10 torr) –slow and expensive oOperates in high vacuum (10 o Next Generation Lithography: EBeam The advantages of electron lithography are: (1) Generation of micron and submicron resist geometries (2) Highly automated and precisely controlled operation (3) Greater depth of focus (4) Direct patterning without a mask The biggest disadvantage of electron lithography is its low throughput (approximately 5 wafers / hour at less than 0.1 µ resolution). Therefore, electron lithography is primarily used in the production of photomasks and in situations that require small number of custom circuits. Next Generation Lithography: E-Beam Electron scattering in resist and substrate The scattered electrons also expose the resist Interaction of e-and substrate + resist leads to beam spreading – Elastic and in-elastic scattering in the resist – Back-scattering from substrate and generation of secondary e– 100 Å e-beam become 0.2 µm line Next Generation Lithography: E-Beam Next Generation Lithography: E-Beam Pattern directly written into resist by scanning e-beam Device is just like an SEM with – On-off capability – Pixelation – Accurate positioning – E-beam blur Next Generation Lithography: EBeam E-beam blur Next Generation Lithography:E-Beam Thermionic emitters: – Electrons “boiled” off the surface by giving them thermal energy to overcome the barrier (work function) – Current given by RichardsonDushmanEquation Field Emitters: – Takes advantage of the quantum mechanical properties of electrons. –Electrons tunnel out when the surface barrier becomes very narrow – Current given by FowlerNordheim equation Photo Emitters: – Energy given to electrons by incident photons – Only photo-electrons generated close to the surface are able to escape SCALPEL® (SCattering with Angular Limitation Projection Electron-beam Lithography) EPL is e-beam with a mask for high-throughput The aspect of SCALPEL which differentiates it from previous attempts at projection electron-beam lithography is the mask. This consists of a low atomic number membrane covered with a layer of a high atomic number material: the pattern is delineated in the latter. While the mask is almost completely electron-transparent at the energies used (100 keV), contrast is generated by utilizing the difference in electron scattering characteristics between the membrane and patterned materials. The membrane scatters electrons weakly and to small angles, while the pattern layer scatters them strongly and to high angles. An aperture in the back-focal (pupil) plane of the projection optics blocks the strongly scattered electrons, forming a high contrast aerial image at the wafer plane SCALPEL® (SCattering with Angular Limitation Projection Electron-beam Lithography) The functions of contrast generation and energy absorption are thus separated between the mask and the aperture. This means that very little of the incident energy is actually absorbed by the mask, minimizing thermal instabilities in the mask. It should be noted that, although the membrane scatters electrons weakly compared to the scatterer, a significant fraction of the electrons passing through the membrane are scattered sufficiently to be stopped by the SCALPEL aperture. Mask easier/simpler than EUV SCALPEL® (SCattering with Angular Limitation Projection Electron-beam Lithography) Next Generation Lithography: xRays X-ray lithography employs a shadow printing method similar to optical proximity printing. The x-ray wavelength (4 to 50 Å) is much shorter than that of UV light (2000 to 4000 Å). Hence, diffraction effects are reduced and higher resolution can be attained. For instance, for an x-ray wavelength of 5 Å and a gap of 40 µ, R is equal to 0.2 µ. Became very important in MEMS: LIGA Despite huge efforts seems abandoned for NGL for now Grenoble Synchrotron Next Generation Lithography: xRays Types of x-ray sources: – Electron Impact X-ray source – Plasma heated X-ray source » Laser heated » E-beam heated – Synchrotron X-ray source Next Generation Lithography: x-Rays Mask: Needs a combination of materials that are opaque (heavy element, e.g. Au) and transparent (low atomic mass membrane, e.g. BN or S3N4) to x-rays Mask written by e-beam Diffraction is not an issue (shadowing is, see next viewgraph) Masks difficult to make due to need to manage stress Dust less of a problem because they are transparent to x-rays Next Generation Lithography: x-Rays On account of the finite size of the x-ray source and the finite mask-to-wafer gap, a penumbral effect results which degrades the resolution at the edge of a feature. An additional geometric effect is the lateral magnification error due to the finite mask-to-wafer gap and the non-vertical incidence of the x-ray beam. The projected images of the mask are shifted laterally by an amount d, called runout. This runout error must be compensated for during the mask making process. Next Generation Lithography:IPL Ion source Ions scatter much less than electrons so a higher resolution is feasible Problems: – Ion Beam source (e.g. Gallium) – Mask – Beam forming – Not as mature as EPL Ion beam Mask Electrostatic lens system (4:1 reduction) Reference plate Step-and-scan wafer stage Vacuum chamber Next Generation Lithography:IPL Ion lithography can achieve higher resolution than optical, x-ray, or electron beam lithographic techniques because ions undergo no diffraction and scatter much less than electrons. In addition, resists are more sensitive to ions than to electrons. The Figure below depicts the computer trajectory of 50 H+ ions implanted at 60 keV. As illustrated, the spread of the ion beam at a depth of 0.4 µ is only 0.1 µ. There is also the possibility of a resistless wafer process. However, the most important application of ion lithography is the repair of masks for optical or x-ray lithography, a task for which commercial systems are available. Next Generation Lithography:IPL IPL Mask e-beam writing PMMA 1m Au 100A 2 m Si3N4 develop electroplating and etch off backside etch Si wafer Future Lithography: Massive Parallel Writing Arrays High-throughput direct-write electron beam lithography. Addressable arrays of negative electron affinity cathodes have been advanced as an approach to improve throughput for electron beam direct - write applications. Massively parallel arrays of atomic force microscopes ( AFMs ). Perhaps the ultimate device in lithography might be achieved by using amorphous Si as a resist in conjunction with a large array of AMFs. Future Lithography:Microcontact Printing Soft lithography: – Replication of a “masterpattern” using PDMS (stamp) – Inking the stamp with molecules (thiols, thioethers, alkoxysilanes, chlorosilanes, etc.) – Contact the stamp with the substrate surface – Monolayer formation at regions of contact Future Lithography: Nano-Imprint Technology Nanoimprintlithography patterns a resist by deforming the resist shape through embossing (with a mold), rather than by altering resist chemical structures through radiation (with particle beams). After imprinting the resist, an anisotropicetching is used to remove the residue resist in the compressed area to expose the underneath substrate. 10nm diameter holes and 40nm pitch in PMMA can be achieved on Sior a metal substrate and excellent uniformity over 1 square inch. Future Lithography: Nanoimprinting Dip Pen Lithography Scanning AFM Nanostencil Cantilever tip with holes Scanning AFM Nanostencil Nanopatterning Methods Compared Homework 1. 2. 3. How does one derive a diameter of 1.22lf/d for the imaging of a small aperture ? What does immersion lithography do to DOF? Demonstrate that F = (1+M)f=1/2NA