MO11 - ICUIL_DPSSL_presentation_vfinal2

advertisement

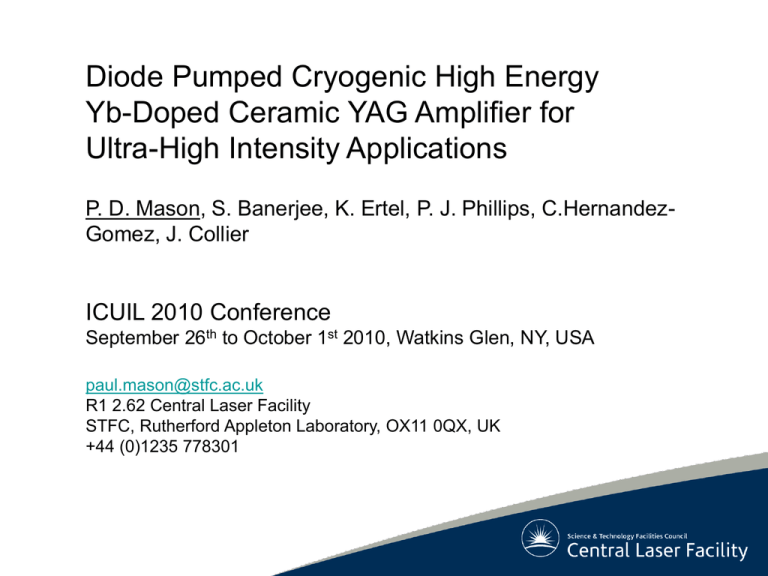

Diode Pumped Cryogenic High Energy Yb-Doped Ceramic YAG Amplifier for Ultra-High Intensity Applications P. D. Mason, S. Banerjee, K. Ertel, P. J. Phillips, C.HernandezGomez, J. Collier ICUIL 2010 Conference September 26th to October 1st 2010, Watkins Glen, NY, USA paul.mason@stfc.ac.uk R1 2.62 Central Laser Facility STFC, Rutherford Appleton Laboratory, OX11 0QX, UK +44 (0)1235 778301 Motivation • Next generation of high-energy PW-class lasers – Multi-Hz repetition rate – Multi-% wall-plug efficiency • Applications – – – – Ultra-intense light-matter interactions Particle acceleration Intense X-ray generation Inertial confinement fusion • High-energy DPSSL amplifiers needed – Pumping fs-OPCPA or Ti:S amplifiers – Drive laser for ICF Beamline Facility Amplifier Design Considerations • Requirement – Pulses up to 1 kJ energy @ 10 Hz, few ns duration, overall > 10% • Gain Medium Long fluorescence lifetime Higher energy storage potential Minimise number of diodes (cost) Available in large size Handle high energies Good thermo-mechanical properties Handle high average power Sufficient gain cross section Efficient energy extraction • Amplifier Geometry High surface-to-volume ratio Efficient cooling Low (overall) aspect ratio Minimise ASE Heat flow parallel to beam Minimise thermal lens Amplifier Concept • Ceramic Yb:YAG gain medium (slabs) – Best compromise to meet requirements – Possibility of compound structures for ASE suppression • Distributed face-cooling by stream of cold He gas – Heat flow along beam direction – Low overall aspect ratio & high surface area – Coolant compatible with cryo operation • Operation at cryogenic temperatures – Reduced re-absorption, higher o-o efficiency – Increased gain cross-section – Better thermo-optical & thermo-mechanical properties • Graded doping profile – Reduced overall thickness (up to factor of ~2) • Lower B-integral – Equalised heat load for slabs Amplifier Parameters • Quasi-3 level model – 1D, time-dependent model – Spectral dependence (abs.) included – Assume Fmax = 5 J/cm2 for ns pulses in YAG • Results – Optimum doping x length product maximum storage efficiency ~ 50% – Optimum aspect ratio to ensure g0D 3 minimise risk of ASE • Highly scalable concept – Just need to hit correct aspect ratio & doping Inputs Pump intensity (each side) Dlpump 5 kW/cm2 5 nm FWHM Pump duration 1 ms Temperature 175 K Results Optimum doping x length Storage efficiency Small signal gain (G0) Optimum Aspect ratio# # 3.3 %cm 50 % 5 J/cm2 stored 3.8 constant doping 0.78 graded doping 1.55 Aperture / length Amplifier Design Parameters HiPER HiLASE / ELI Prototype DiPOLE ~ 1 kJ ~ 100 J ~ 20 J 14 x 14 cm 200 cm2 4.5 x 4.5 cm 20 cm2 2 x 2 cm 4 cm2 Aspect ratio 1.4 1.3 1 No. of slabs 10 7 4 1 cm 0.5 cm 0.5 cm 5 4 2 0.33 at.% 0.97 at.% 1.65 at.% Extractable energy Aperture Slab thickness No. of doping levels Average doping level DiPOLE Prototype • Diode Pumped Optical Laser for Experiments – Circular 55 mm diameter x 5 mm thick – Cr4+ cladding for ASE management – Two doping concentrations 1.1 & 2.0 at.% • Progress to date – Ceramic discs characterised – Amplifier head designed & built • CFD modelling of He gas flow • Pressure testing – Cryo-cooling system completed – Diode pump lasers being assembled – Lab. refit near completion Pump 2x2 cm² Yb3+ 35 mm • 4 x co-sintered ceramic Yb:YAG slabs 55 mm – 10 to 20 Joule prototype laboratory test bed Cr4+ Ceramic Yb:YAG Discs • Transmission spectra • Uncoated, room temperature 1030 nm 940 nm Fresnel limit ~84% • Transmitted wavefront PV 0.123 wave Amplifier Head • Head layout • CFD modelling • Vacuum vessel 2 cm 1.1% Pump Pump 2.0% He flow Predicted temperature gradient in Yb:YAG amplifier disc Uniform DT across pumped region ~ 3K Cryo-cooling System Vacuum insulated transfer lines Amplifier head Helium cooling circuit Cryostat Diode Pump Laser • Built by Consortium – Ingeneric: Opto-mechanical design & build – Amtron: Power supplies & control system – Jenoptic: Laser diode modules • Specifications – 2 pump units – left & right handed – l0 = 940 nm, DlFWHM < 6 nm – Peak power 20 kW – Pulse duration 0.2 to 1.2 ms – Pulse repetition rate variable 0.1 to 10 Hz • Other specs. independent of PRF Diode Pump Laser • Beam profile specification – Uniform square profile Spatial profiles (Modelled) Near Field Far Field – Steep profile edges – Low (<10°) symmetrical divergence • Demonstrated performance – Square beam shape – Low-level intensity modulations – Steep edge profiles – 20 kW peak output power • High confidence that other specifications will be demonstrated shortly Preliminary measurement Lab Layout LN2 tank Cryo-cooling system Optical tables Floor area ~30 m2 Amplifier Next Steps • Short-term (3 to 6 months) – Complete lab. refit – Install & test cryo-cooler & diode pump lasers – Characterise amplifier over range of temperature & flow conditions • • • • Spectral measurements (absorption, fluorescence) Thermo-optical distortions (aberrations, thermal lensing etc.) Opto-mechanical stability Small signal gain & ASE assessment • Long-term (6 to 12 months) – Specify and build front-end system • Shaped seed oscillator & regen. amplifier – Complete design of multi-pass extraction architecture (8 passes) – Amplify pulses • Demonstrate >10 J, 10 Hz, >25 % o-o efficiency Any Questions ? Yb-doped Materials Parameter (at RT) Glass S-FAP YAG CaF2 940-980 / 1030 900 / 1047 940 / 1030 940-980 / 1030 ~ 2.0 ~ 1.3 ~ 1.0 ~ 2.4 Emission cross-section (peak x10-20 cm2) 0.7 6.2 3.3 0.5 Gain Low High Medium Low 0.1 to 1.2 1.5 2.7 0.43 High > 50 nm Low OK? High > 50 nm Availability of large aperture Good Limited OK (Ceramic) Limited (Ceramic) Thermal properties (K in Wm-1K-1) Poor 1.0 OK 2.0 Good 10.5 OK 6.1 Wavelengths (pump/emission in nm) Fluorescence lifetime (msec) Non-linear index (n2 x 10-13 esu) Bandwidth Yb:YAG Energy Level Diagrams • Room temperature (300K) • Cryogenic cooling (175K) Quasi-3 Level f13=4.6% 7/2 Yb3+ 940 nm 2F 1030 nm 5/2 Re-absorption loss 1030 nm Low quantum defect (QD) lp/ llas~ 91% 2F 2F 5/2 940 nm 2F 4 Level-like Significantly reduced re-absorption loss f13=0.64% 7/2 Yb3+ Temperature Dependence Operating fluence T=300K Pump Fluence (J/cm²) Small Signal Gain Storage Efficiency (%) T=175K Doping Profile (1 kJ Amplifier) Pump Absorption Absorption + Pump Spectra Efficiency vs. lpump 175 K 300 K Pump, FWHM = 5nm 175 K, 10 kW/cm2 300 K, 20 kW/cm2 Absorption Spectra 1030 nm 940 nm Factor of 2 Ceramic YAG with Absorber Cladding Sample of Co-Sintered YAG (Konoshima) Reflection at Interface? Laser Cr4+:YAG Camera a b c ? Yb:YAG Yb:YAG Cr4+:YAG a c b Nothing! Beamline Efficiency Modelling • Beamline parameters – 2 amplifiers, 4-passes – 1% loss between slabs, 10% loss after each pass (reverser & extraction) – Losses in pump optics ignored Amp 2 Amp 1 Extraction Beam Transport Reverser 1 Reverser 2 Injection Injection Losses: Amp1 + 2 17.4 % (distributed) Reverser 1 Amp1 + 2 10 % 17.4 % (distributed) Reverser 2 10 % Amp1 + 2 17.4 % (distributed) Reverser 1 10 % Amp1 + 2 17.4 % (distributed) Extraction 10 %