Technology Thin films ZnO:Al were prepared by RF diode sputtering

advertisement

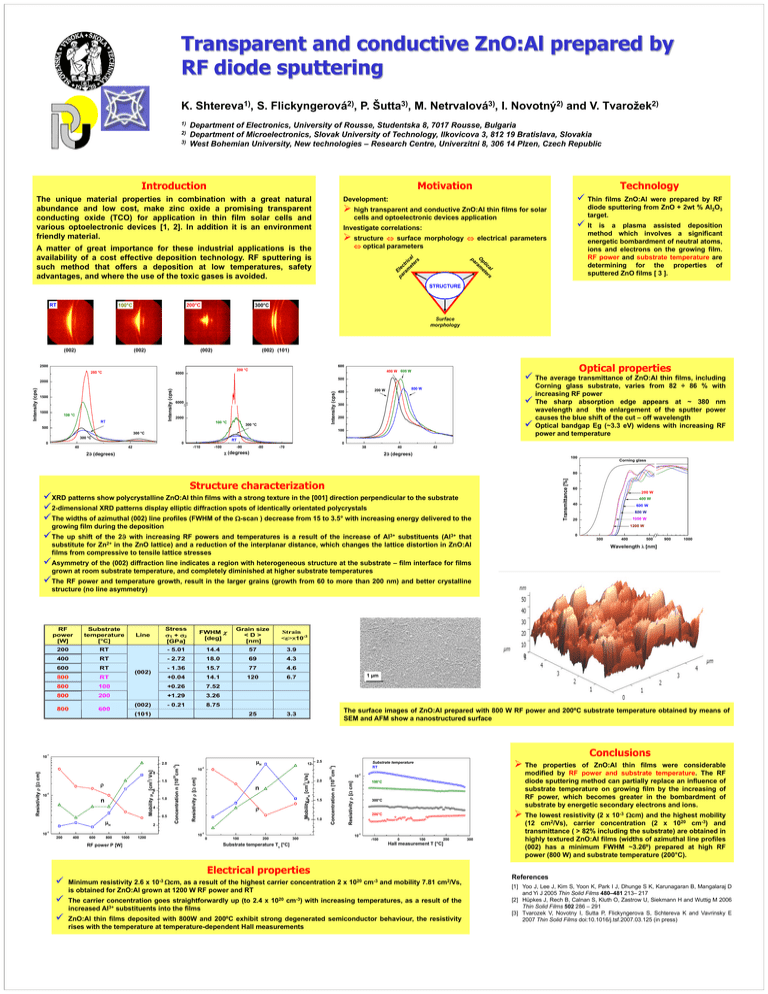

Transparent and conductive ZnO:Al prepared by RF diode sputtering K. Shtereva1), S. Flickyngerová2), P. Šutta3), M. Netrvalová3), I. Novotný2) and V. Tvarožek2) 1) Department of Electronics, University of Rousse, Studentska 8, 7017 Rousse, Bulgaria Department of Microelectronics, Slovak University of Technology, Ilkovicova 3, 812 19 Bratislava, Slovakia West Bohemian University, New technologies – Research Centre, Univerzitni 8, 306 14 Plzen, Czech Republic 2) 3) Motivation Introduction The unique material properties in combination with a great natural abundance and low cost, make zinc oxide a promising transparent conducting oxide (TCO) for application in thin film solar cells and various optoelectronic devices [1, 2]. In addition it is an environment friendly material. Technology Thin Development: films ZnO:Al were prepared by RF diode sputtering from ZnO + 2wt % Al2O3 target. high transparent and conductive ZnO:Al thin films for solar cells and optoelectronic devices application It is a plasma assisted deposition method which involves a significant energetic bombardment of neutral atoms, ions and electrons on the growing film. RF power and substrate temperature are determining for the properties of sputtered ZnO films [ 3 ]. Investigate correlations: structure surface morphology electrical parameters optical parameters A matter of great importance for these industrial applications is the availability of a cost effective deposition technology. RF sputtering is such method that offers a deposition at low temperatures, safety advantages, and where the use of the toxic gases is avoided. STRUCTURE RT 200°C 100°C 300°C Surface morphology (002) (002) (002) (002) (101) 200 °C 200 °C 8000 400 W 600 W The average transmittance of ZnO:Al thin films, including 500 1500 1000 100 °C RT Intensity (cps) Intensity (cps) 2000 Intensity (cps) Optical properties 600 2500 6000 2000 100 °C 300 °C 500 400 300 200 100 300 °C 300 °C RT 0 0 40 800 W 200 W -110 42 -100 0 -90 -80 -70 38 40 (degrees) 2 (degrees) Corning glass substrate, varies from 82 ÷ 86 % with increasing RF power The sharp absorption edge appears at ~ 380 nm wavelength and the enlargement of the sputter power causes the blue shift of the cut – off wavelength Optical bandgap Eg (~3.3 eV) widens with increasing RF power and temperature 42 2 (degrees) 100 Corning glass Transmittance [%] 80 Structure characterization XRD patterns show polycrystalline ZnO:Al thin films with a strong texture in the [001] direction perpendicular to the substrate 2-dimensional XRD patterns display elliptic diffraction spots of identically orientated polycrystals The widths of azimuthal (002) line profiles (FWHM of the -scan ) decrease from 15 to 3.5° with increasing energy delivered to the 60 200 W 400 W 40 600 W 800 W 1000 W 20 growing film during the deposition 1200 W The up shift of the 2 with increasing RF powers and temperatures is a result of the increase of Al3+ substituents (Al3+ that 0 300 substitute for Zn2+ in the ZnO lattice) and a reduction of the interplanar distance, which changes the lattice distortion in ZnO:Al films from compressive to tensile lattice stresses 400 500 900 1000 Wavelength [nm] Asymmetry of the (002) diffraction line indicates a region with heterogeneous structure at the substrate – film interface for films grown at room substrate temperature, and completely diminished at higher substrate temperatures The RF power and temperature growth, result in the larger grains (growth from 60 to more than 200 nm) and better crystalline structure (no line asymmetry) Stress 1 + 2 [GPa] FWHM [deg] Grain size <D> [nm] RT - 5.01 14.4 57 3.9 400 RT - 2.72 18.0 69 4.3 600 RT - 1.36 15.7 77 4.6 800 RT +0.04 14.1 120 6.7 800 100 +0.26 7.52 800 200 +1.29 3.26 - 0.21 8.75 25 3.3 RF power [W] Substrate temperature [°C] 200 800 Line (002) (002) 600 (101) Strain <>x10-3 1 µm The surface images of ZnO:Al prepared with 800 W RF power and 200ºC substrate temperature obtained by means of SEM and AFM show a nanostructured surface -1 n 1.0 4 H 2 0.5 -3 10 -3 n 2.0 6 1.5 3 1.0 -3 200 400 600 800 1000 1200 0 100°C 300°C The lowest resistivity (2 x 10-3 cm) and the highest mobility 200°C 100 200 300 10 -100 0 100 200 Hall measurement T [°C] Substrate temperature Ts [°C] RF power P [W] -2 -3 10 Electrical properties 10-3 cm, Minimum resistivity 2.6 x as a result of the highest carrier concentration 2 x is obtained for ZnO:Al grown at 1200 W RF power and RT 1020 cm-3 Conclusions properties of ZnO:Al thin films were considerable modified by RF power and substrate temperature. The RF diode sputtering method can partially replace an influence of substrate temperature on growing film by the increasing of RF power, which becomes greater in the bombardment of substrate by energetic secondary electrons and ions. 10 20 9 The Substrate temperature RT Resistivity [ cm] -2 10 2 20 6 -2 Mobility H [cm / Vs] 2 1.5 2.5 10 Resistivity [ cm] Mobility H [cm / Vs] Resistivity [ cm] 8 12 Concentration n [10 cm ] H -3 2.0 Concentration n [10 cm ] 10 and mobility 7.81 cm2/Vs, The carrier concentration goes straightforwardly up (to 2.4 x 1020 cm-3) with increasing temperatures, as a result of the increased Al3+ substituents into the films ZnO:Al thin films deposited with 800W and 200ºC exhibit strong degenerated semiconductor behaviour, the resistivity rises with the temperature at temperature-dependent Hall measurements 300 (12 cm2/Vs), carrier concentration (2 x 1020 cm-3) and transmittance ( > 82% including the substrate) are obtained in highly textured ZnO:Al films (widths of azimuthal line profiles (002) has a minimum FWHM ~3.26º) prepared at high RF power (800 W) and substrate temperature (200°C). References [1] Yoo J, Lee J, Kim S, Yoon K, Park I J, Dhunge S K, Karunagaran B, Mangalaraj D and Yi J 2005 Thin Solid Films 480–481 213– 217 [2] Hüpkes J, Rech B, Calnan S, Kluth O, Zastrow U, Siekmann H and Wuttig M 2006 Thin Solid Films 502 286 – 291 [3] Tvarozek V, Novotny I, Sutta P, Flickyngerova S, Schtereva K and Vavrinsky E 2007 Thin Solid Films doi:10.1016/j.tsf.2007.03.125 (in press)