Defense Presentation

advertisement

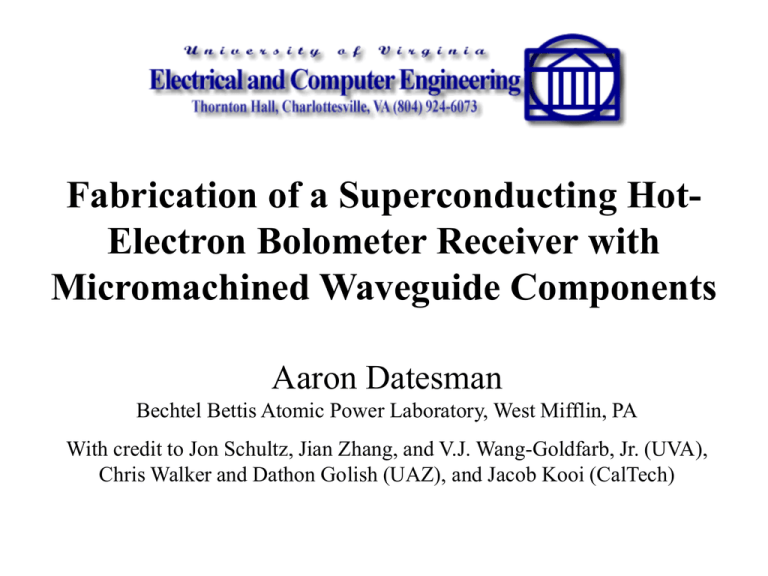

Fabrication of a Superconducting HotElectron Bolometer Receiver with Micromachined Waveguide Components Aaron Datesman Bechtel Bettis Atomic Power Laboratory, West Mifflin, PA With credit to Jon Schultz, Jian Zhang, and V.J. Wang-Goldfarb, Jr. (UVA), Chris Walker and Dathon Golish (UAZ), and Jacob Kooi (CalTech) (Stratospheric Observatory for Infrared Astronomy) • 5 – 300 microns wavelength • 9 first-light instruments including GREAT and CASIMIR • First light winter 2005! www.sofia.arc.nasa.gov SOfIA’s IR Science: • Interstellar cloud physics and star formation in our galaxy. • Proto-planetary disks and planet formation in nearby star systems. • Origin and evolution of biogenic atoms, molecules, and solids. • Composition and structure of planetary atmospheres and rings, and comets. • Star formation, dynamics, and chemical content of other galaxies. • The dynamic activity in the center of the Milky Way. • Ultra-luminous IR Galaxies (ULIRGS) as a key component of the early universe. More than 120 molecular species identified in ISM and interstellar gas clouds. Submillimeter wavelength regime is very rich in the rotational transitions of these molecules. Protostellar 4448-mm Nisini 1999 / CFA Mixers/Mixer Elements Schottky diodes, SIS junctions, and hot-electron bolometers (HEBs) Complementary technologies based upon cryogenic cooling requirements and the superconducting energy gap Signal Mixer IF Amplifier IF Spectrum Analyzer Local Oscillator Spectral Intensity (a.u.) Gerecht, 1998 PHEB mixers have been installed on ground-based telescopes f fIF 1 LO fsig 850 851 Frequency (GHz) PROJECT OVERVIEW: (what’s new here?) • Receiver is a 5-Element Array of HEB Mixers for 1450 GHz Yield and Uniformity are Vital • Focused-Ion Beam (FIB) Definition of DHEB Microbridges Exploring the application of this tool as an alternative to EBL • Waveguide Components Micromachined from Silicon Inexpensive, Flexible, and Fast • HEB Mixers on Silicon Nitride Membranes With backshort underneath the probe, easy to make an array • Device Passivation Scheme Using Sputtered Germanium Niobium is a refractory metal, and thin Nb films oxidize readily. YIELD and ESD • Nb DHEBs are extremely susceptible to destruction by Electrostatic Discharge (ESD). Development of a fabrication process which suppresses or minimizes ESD problems was a very important part of this research. Re-ordering of the fabrication process steps, proper design of test equipment, improved awareness about how to operate processing equipment, and reduced handling of finished dies were all part of this effort. The large die size, choice of substrate (Si), and passivation all may also have helped. • Correspondingly, DHEB fabrication yields are low One researcher [Ganzevles] reported a yield of (a fraction of) 5%. • To achieve a 50% yield with a 5-element array, x5=0.5 or the individual device yield MUST EXCEED 87%!! Bolometer Pin Mixer Absorber Heat Capacity C G Tbath C th 1 3 dB G P I R0 PLO 2 PLO PRF e 2 0 jIF t IF = RF - LO Thermal Conductance to Bath Temp. . V = VRFexp(jRFt) + VLOexp(jLOt) Hot-Electron Effect • Electrons and phonons do not interact, Tp ≠ Te (very clean semiconductor, or very thin dirty superconductor) Electron Gas Bolometer th • Absorber is therefore only the electron gas; the lattice does not play a role. Heat capacity C is minimized. Phonon-cooled HEB (PHEB) Diffusion-cooled HEB (DHEB) Superconducting Thin Film 1 m I0 Normal Metal Contacts I0 0.15 m 0.3 m 5 m Pin Pin t = 3.5 nm e e-e e e e-ph esc e-e e e e diff. t = 10 nm Superconducting Microbridge th e ph L / 2 D e ph 0.3 m f3dB≈10 GHz (NbN) f3dB≈4 GHz (Nb) Diffusion-cooled HEB Operation • “Diffusion” refers to the flow of heat, not carrier transport • Microbridge is a distributed, not lumped, element e Local Electron Temperature T (K) 7.5 eff 7 6.5 6 TC 5.5 5 4.5 4.2 K 4 0 0.2 0.4 0.6 x/L 0.8 1 f 3dB 2 L D 2 1 2 L Hot-Spot Mixing •Combination of RF & LO signals in a square-law detector creates IF “beat” • Diffusion of heat to contacts creates temperature profile, which responds to the IF variation • Normally conducting hot spot grows and shrinks in response, creating a timevarying resistance at the IF and an IF voltage signal. 1x4 Array of Nb superconducting DHEB mixers for 850 GHz operation Wire-Frame Assembly Drawing • Waveguide channel (140 m x 70 m) • Waveguide probe & mixer circuitry • Photonic crystal junctions (PCJs) • Backshort cavity Mixer Circuitry • Semicircular waveguide probe • Diffusion-cooled HEB • Chokes, filters, and IF lines FIB-Sculpted Probe Transition and Finished DHEB Microbridge • Feature could not be fabricated reliably by photolithography and liftoff • Integral part of the HEB fabrication process using the FIB Laser Micromachining of Silicon – Feedhorn Block Fabrication • Fast (105 m3/sec) laser microchemical etching w/out reference to crystal planes • Also used for backshort & PCJs 1x4 Array of Nb superconducting DHEB mixers for 850 GHz operation Backshort Block – HEB Block – Feedhorn Block Alignment Schemes Backshort Block – Pyramidal Stubs and Corner Compensation • Immersive etching using a solution of KOH:IPA at 80 C with a Si3N4 mask • 127 ± 0.3 m depth is significantly better than the design tolerance Concave corner Compensation scheme Dimensions in microns Fabrication Procedures • Each starts with a silicon wafer covered on both sides by LPCVD Si3N4 • Dicing occurs in the middle of the HEB Block procedure, before the devices are fabricated. Therefore, FIB processing is performed on individual dies. Backshort Block 1. RCA Clean 2. Silicon Etch Litho. 3. Si3N4 Etch 4. Photoresist Removal 5. Backside Markers 6. Silicon Etch 7. Si3N4 Removal 8. Laser μMachining 9. Metallization 10. Dicing HEB Block 1. Liftoff Stencil Fab. 2. Depo. & Liftoff 3. Membrane Etch Litho. 4. Si3N4 Etch 5. Membrane Etch 6. Dicing 7. Imaging Au Depo. 8. FIB1-3 9. Bridge Etch & Msr. 10.Germanium Depo. 11.Passivation Litho. 12.Ge/Nb RIE Etch 13.Packaging HEB Block Fabrication • Circuits rest upon silicon nitride membranes 0.75 m thick. • Deposition occurs under a single vacuum, assuring a clean interface. • Niobium serves both for the device layer and as an RIE etch mask. • Silicon nitride serves as the mask for the membrane etch, which is performed using a meniscus etching technique. • Dicing follows the membrane etch, but still occurs in the middle of the process. • Sputtered Ge is used as the passivation material. Nb Etch Mask 300 Å Gold 3000 Å Microbridge Nb 100 Å Focused-Ion Beam HEB Fabrication Gallium Focused-Ion Beam (FIB) • Beam waist 550 Å at 350 pA • FIB1-3 process sculpts bridge kernel with about 1000 Å of gold remaining; removes Nb mask • Microbridges as small as 0.15 m x 0.10 m have been fabricated FIB3 Pattern Alignment • Milling with gallium not selective between Nb and Au • Tilting stage at an angle allows removal of just the top of the kernel and prevents contamination • Length of FIB3 cut determines microbridge length FIB View of Finished Kernel • Geometry determines FIB3 width • Must align and focus FIB3 pattern, which varies from device to device • Kernel thickness may vary as much as 200 Å • Contamination of microbridge occurs during FIB2, and during FIB3 focusing Stress of Thin Nb Films Deposited on to Silicon/Si3N4 Substrates • Compensate for target erosion with continued use • Devices made from films with high stress exhibit poor superconductive properties. • Stress of films on Si/SiO2 substrates was controllable and repeatable (not shown). • Stress of films on Si/Si3N4 was never very repeatable, but may have been controllable prerefurbishment • All of the devices described later in this talk were fabricated post-refurbishment. Region Implanted by FIB2 & FIB3 Top Surface in Contact with Kernel Gold Actual Orientation of Gallium Ion Flux at Angle to Exposed Surface Region Implanted by FIB2 Bottom Surface in Contact with Substrate Gallium Ion Flux Assumed Normal Incidence to Exposed Edge of Microbridge Gallium Contamination • 30 keV Ga in Nb: Rlong = 125 Å, Rlat = 49 Å • 10 x 1018 cm-3 threshold: FIB2: 200 Å (60% free) FIB3: 330 Å (* variable *) • Peak dose 1021 cm-3 (2%) from FIB2 Further Materials Issues • Gold misbehaves. Niobium is OK even though it oxidizes and reacts with Ge. Melty & clumpy Non-uniform bridge etch Lengths are short • Gold is removed from the microbridge kernel with a low-power argon RIE etch which is selective to niobium. • Because the bridge etch is non-uniform, the devices must be significantly overetched. (Also, wider microbridges etch more slowly than narrow ones.) • The HEB microbridges respond robustly to this treatment (left, 300 Volts) Devices Fabricated with a 300 Volt Argon RIE Bridge Etch HEB08 HEB10T – HEB14T (pictured) • FIB2 gap 54 pixels, FIB3 0.2 m • FIB2 gap 28 pixels, FIB3 0.3 m • 0.12 m long x 0.32 m wide • 0.22 m long x 0.17 m wide • 45 min. etch in 3 stages • 75 W target resistance (50 W LHe) • 31 ± 3 W RT resistance (83 W/□) • Undiced, not membrane etched Devices Fabricated with a 300 Volt Argon RIE Bridge Etch, cont’d Results: •Uniformity ± 26%, often better • “Yield” 37/38 • 4 sets within 20% of 75 W RT Variation Between Sets: • Two not etched in stages • Uncontrolled thin film stress • Magnification calibration • RIE chamber conditioning Variation Within a Set: • Width ±0.01 m – 6% • Kernel thickness (200 Å) – 5% Devices Fabricated with a 150 Volt Argon RIE Bridge Etch HEB19 & HEB21 • FIB2 gap 22 pixels, FIB3 0.30 m • 0.19 m long x 0.12 m wide • FIB3 depth 0.15 m • Etch times 90 – 220 minutes • “Yield” 12/13; not enough devices were made for statistical validity • Single dies, membrane etched, greased down on a clean glass slide • Pictured device 32 W/□ at LHe • RRR = 1.40 – 1.70 Resistive Transitions • “A” – Silicon nitride, no membrane, oxidized 13 hours then passivated (105 W) • “B” – Quartz, oxidized 16 hours (121 W) • “C” –Silicon nitride, membrane, passivated immediately (62 W) Current – Voltage Characteristics • “A” – Silicon nitride, no membrane, oxidized 13 hours then passivated (105 W) • “B” – Quartz, oxidized 16 hours (121 W) • “C” –Silicon nitride, membrane, passivated immediately (62 W) Device “C”, I-V vs. Temp. Similar to other published results, except: • No negative differential resistance (NDR) • No hysteresis (OK) WHY? Normally conducting edges Transition temperature gradient Device “C”, I-V w/10 GHz RF • Absorbs 10 GHz RF radiation, which drives the microbridge resistive • Suggests device should act as a terahertz hot-spot mixer CONCLUSIONS: • Use and limitations of FIB fabrication were explored. Inconsistent magnification calibration Non-uniform microbridge widths • “Yield” of >90% was observed ESD suppression Passivation with sputtered germanium • Devices near the 10 K target resistance were manufactured 150 Volt etch not superior to 300 Volt bridge etch (50 W/□) Device resistance uniformity of ±25% or better • Negative differential resistance was not observed Complicated graded structure exists in both dimensions • Finished 1x5 arrays have been sent to UAZ. Gallium Implantation Experiments • 30 keV Ga+ into 100 Å Nb/100 Å Au film • Reduction in TC and increasing resistance with increasing dose • Idea: FIB trimming of finished HEBs! Anomalous Increase of the Contact Pad Transition Temperature Curve Dose (1019 cm-3) T (K) R (Ω) 10 K R (Ω) DR (Ω) 0 0 n/a n/a 18.2 n/a A 2.7 6 5.5 19.5 14 B 10.6 5.5 8.1 22.3 14.2 C 21.4 5 11.5 26 14.5 Additional Slides Demonstrating that gold etches off of wider microbridges more slowly, and that uncontrolled stress may be responsible for the variation between sets (HEB10) Suggesting that an inconsistent magnification calibration may be to blame for some non-uniformity, especially for very narrow microbridges Gallium Contamination Curve Residual Resistance Ratio