DuraShield KPE

advertisement

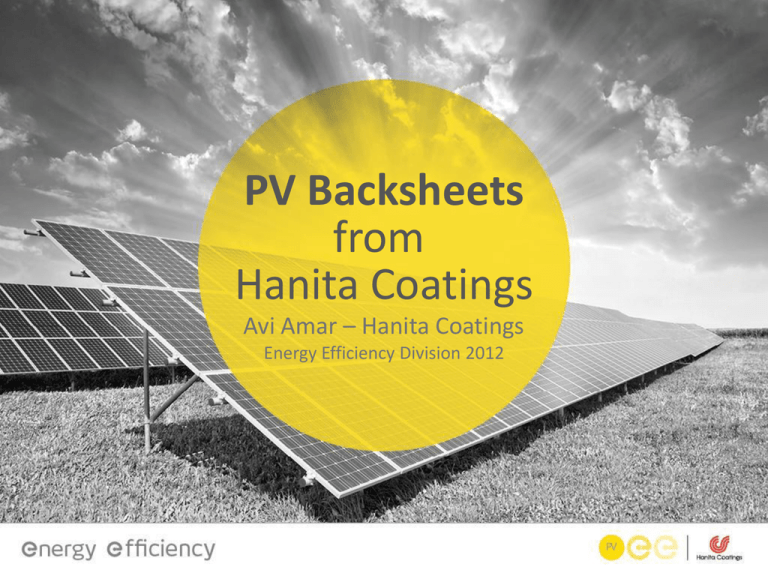

PV Backsheets from Hanita Coatings Avi Amar – Hanita Coatings Energy Efficiency Division 2012 Why should you choose Hanita? Hanita Coatings offers 30 years’ expertise developing engineered polymeric films Established – 1982 HQ, R&D and manufacturing in Western Galilee, Israel Ownership – • • 75% Kibbutz Hanita 25% Tene Investments 180 staff, 7 overseas sales offices W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom Hanita’s global reach ensures short lead-times and outstanding local service W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom State-of-the art coating and laminating facilities provide innovative technological solutions Four coating lines 1.6-2.1m wide, 0.7m pilot production line, clean room – Class 100,000 W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom Technology break-throughs in the field of metallizing enable us to provide world-leading levels of barrier Two vacuum roll coaters, 2.1m, 2.3m wide, proprietary deposition of Al, Cu, and other metals, alloys and oxides W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom Recent CAPEX investments of $15m provide the cutting edge of technology Six slitter-rewinders with width capacity from 5mm – 2100mm, Clean room – Class 10,000 W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom We offer a unique range of capabilities and processes under one roof Deposition & Metallizing Technology Coating & Laminating Technology Technology Print Primers Adhesives Barrier Coatings Abrasion Resistant Coatings Nano Coatings Ultra Violet Reduction Atmospheric Plasma Optical Density 0.2-5 Enhanced Metal Adhesion Reactive Depositions Clear Barrier R&D Engineered Films Markets Energy Efficiency Solutions Industrial & Graphics W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom With all production in one site, we can guarantee total quality control W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom A fully equipped testing lab ensures all products are rigorously tested for durability & performance W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom All backsheets we develop are rigorously tested as complete modules by external laboratory Before and after exposure tests Dry/Wet Hi Pot insulation test Thermal cycling testing Damp heat test @ Lamination testing 200 cycles • 1000 hours • 2000 hours • 3000 hours • Inner layer • Encapsulant adhesion W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom Our products combine the finest raw materials from leading manufactures EVA Films Ultra-white patent pending EVA layer gives high VIS light reflectance (higher output power from the module) + good adhesion to EVA encapsulant. PET Films Fluoropolymeric Films Selected to provide the required electrical insulation and mechanical strength. Arkema Kynar® films give outstanding protection from weathering Fluoropolymeric coatings W hy H a nita B a ck she e ts: K PE C PE K A PE B ack - C ontact C ustom In-house coating development cost effectively provides the weatherability levels of FP films Hanita Coatings’ strengths ensure we can challenge the market leaders R&D - Custom Development • Advanced film converting facility • Deep specialization in durable coatings 30 years’ expertise • 12% workforce R&D dedicated • ISO 9001:2008 • Fully equipped Test lab W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom • Distribution centers worldwide Global Reach Why choose DuraShield backsheet products? Look what can happen if you use the wrong backsheet… Corrosion in connections caused by cracks in backsheet Delamination of BS after 3 years exposure in Germany W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom All DuraShield backsheets provide high physical protection, electrical insulation & the right appearance Physical protection Increased efficiency in some applications Enabling a 25 year outdoor PV module lifespan Right appearance Electrical insulation Moisture protection W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom Hanita produces four types of backsheets (BS) for the leading PV technologies DuraShield KPE DuraShield CPE DuraShield KAPE DuraShield Back Contact Fluoropolymer laminate BS, for c-Si modules High durability FP coated laminate BS, for c-Si modules Low weight, high barrier BS solution for Thin Film technologies Electrical circuit backsheet for Back Contact (EWT/MWT) technologies W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KPE’s classic FP film construction delivers enhanced long-term performance for c-Si modules DuraShield KPE K = Kynar® PVDF Fluoropolymeric film P = Polyester film E = EVA W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KPE is a proven technology targeting traditional module manufacturers Cost Effective Economical alternative to PVF constructions Enhanced Reflectivity Excellent Durability Exceptionally white EVA layer Long term weatherability retains bright whiteness and reflectivity W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KPE is TUV certified for >1000VDC and UL IEC 61730-2:2004 Maximum permissible System voltage 1053 VDC W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KPE easily withstands W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield CPE replaces the Kynar FP film laminate with an equally durable Fluoropolymeric coating DuraShield CPE Cost Effective C = Coating of Fluoropolymer P = Polyester film E = EVA W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom The DuraShield CPE solution delivers a price advantage without compromising performance EVA PET Patent pending ultra-white EVA layer gives high VIS light reflectance (higher output power from the module) + good adhesion to EVA encapsulant. Provides electrical insulation and mechanical strength. Protected by Fluoropolymer layer. Fluoropolymer Coating Gives protection from weathering, cost effectively. W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KPE gained TUV & UL approval. So did the competitors. Look what happened after 2000 hours… Competitor Backsheet ∆E = 4.4 DuraShield KPE ∆E = 2.0 Market leading competitor’s backsheet yellows drastically after aging test of 2000 hours of damp heat. DuraShield KPE is more reflective and more effective than the competitor’s leading product. W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KPE and CPE show outstanding long term EVA encapsulant peel strength 120 100 DuraShield DuraShield KPE CPE N/cm 80 60 40 20 – FP coating 0 0hrs 1000hrs 2000hrs Damp Heat hours KPK KPE FPE CPE PPE Damp Heat Test 3000hrs – PET based – FP film x2 – DuraShield CPE Damp heat: 85 OC 85% RH W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom – DuraShield KPE DuraShield’s ultra-white EVA shows exceptional initial cell-side reflectance 85 DuraShield KPE 84 83 82 DuraShield CPE %R 81 80 79 78 77 – FP coating 76 – PET based 75 400 450 FPE 500 550 PPE 600 Wavelength (nm) KPE 650 700 KPK 750 800 CPE DuraShield KPE visible light reflectance (550nm): 84.4% DuraShield CPE visible light reflectance (550nm): 84.1% W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom – FP film x2 – DuraShield CPE – DuraShield KPE UV exposure up to 3000 hours shows exceptional performance by DuraShield KPE & CPE @ cell side DuraShield CPE Delta E 8 7 6 5 4 3 2 1 0 DuraShield KPE – FP coating – PET based 1000hrs 2000hrs QUV hours 3000hrs Test cycle: 20h UV-A (0.93W/sq.m,@340nm) + 75°C ; 4h dark + 50°C + condensation – FP film x2 – DuraShield CPE – DuraShield KPE DuraShield KPE and CPE both demonstrate excellent color stability – ΔE vs. QUV hours @ back side 2.50 2.00 ΔE 1.50 DuraShield KPE DuraShield CPE 1.00 0.50 – FP coating 0.00 1000hrs 2000hrs QUV (hrs) KPK KPE FPE CPE 3000hrs PPE Test cycle: 20h UV-A (0.93W/sq.m,@340nm) + 75°C ; 4h dark + 50°C + condensation According to relevant data, 1 year in Florida direct sunshine is ~956 hours in these test conditions. Backside not directly exposed to sunlight, it will typically see ~15-20% from direct light. Taking this factor into account, ~5000 hours safely simulate 25 years W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom – PET based – FP film x2 – DuraShield CPE – DuraShield KPE DuraShield KPE and CPE retain their initial levels of gloss (60°) for 3000 hours virtually without change Gloss Retention (60° Gloss) 120 DuraShield KPE 100 80 DuraShield CPE 60 40 20 – FP coating 0 0 500 KPK 1000 KPE 1500 2000 QUV Hours FPE 2500 3000 3500 – PET based – FP film x2 PPE CPE Test cycle: 20h UV-A (0.93W/sq.m,@340nm) + 75°C ; 4h dark + 50°C + condensation – DuraShield CPE – DuraShield KPE Hanita has developed backsheets for alternative & promising PV technologies DuraShield DuraShield Back KAPE Contact Low weight, high barrier BS solution for Thin Film technologies Electrical circuit BS for Back Contact/MWT technology DuraShield Back Contact Electrical circuit BS for Back Contact (EWT/MWT) technologies W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KAPE delivers the high moisture and oxygen barrier demanded by thin film modules DuraShield KAPE K = Kynar® black PVDF Fluoropolymeric film A = Aluminum P = Polyester film E = Black EVA W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield KAPE is TUV certified for >1000VDC Maximum permissible system voltage 1092 VDC W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom Back Contact breakthrough technology improves cell module power output distribution Back contact technology provides • Higher output power • Lower manufacturing costs • No stringing/bus-bars • Attractive appearance DuraShield Back Contact foil innovation enables greater efficiency at reduced cost DuraShield Back Contact W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom DuraShield Back Contact foil innovation enables greater efficiency at reduced cost DuraShield Back Contact Innovation Compatibility Performance Patent pending technology replaces expensive 36µ copper foil with Aluminum conductive layer Compatible with all existing conductive adhesives and solder pastes Achieves the optimal fill factor by using highly conductive layers W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom Our specialty is customized backsheet development, providing the solution to your specific product challenge Problem: LCPV low concentrated PV modules suffer accelerated module degradation Goal: Improve weatherability Solution: Engineering EVA to enhance UV resistance Problem: unconventional encapsulant material Goal: improve affinity to BS Solution: Engineering of BS surface by primer or co-ex development, or by replacing EVA with alternative film. W hy H a nita B ack she e ts : K PE C PE K A PE B ack - C ontact C ustom So how can Hanita help you solve your product challenge? R&D - Custom Development • Advanced film converting facility • Deep specialization in durable coatings 30 years’ expertise • 12% workforce R&D dedicated • ISO 9001:2008 • Fully equipped Test lab W hy H a nita B ack she e ts: K PE C PE K A PE B ack - C ontact C ustom • Distribution centers worldwide Global Reach Thank you! pv@hanitacoatings.com