Energy Efficient Turbo Blowers for Aeration

advertisement

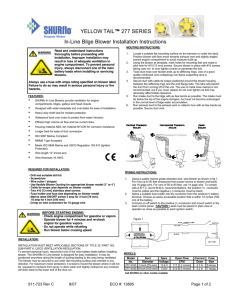

One Day National Workshop on Common Effluent Treatment Plants CII - Sohrabji Godrej Green Business Centre, Hyderabad Energy Efficient Turbo Blowers for Aeration Kiron C. Pande - Godrej & Boyce Mfg. Co. Ltd. Technical Session II: Treatment Technologies & Monitoring 23 November 2012 23/11/2012 company presentation 2012 Page 1 Effluent Water Treatment Energy Cost Aeration Pretreatment Dewatering & Sludge treatment 33% 24% 43% Page 2 Positive Displacement type, Twin Lobe Air Blower Page 3 Increasing Energy Efficiency PD Volumetric Turbo - η Increase over 10% - No Volumetric pulsation Low speed Turbo - η Increase over 10% High Speed Turbo High Gear Ratio Roots blower -η Increase over 20% - Increase stability Direct driven High Speed Multi stage Turbo blower Multi stage Turbo blower Blower Efficiency Increased over 40% Page 4 Turbo Blowers Page 5 Page 6 User selectable Control Modes with KTurbo • Constant Flow • Constant Pressure • Constant Power • D.O. Control Page 7 User Selectable Control Modes Constant Current Mode Constant Pressure Mode Constant Flow Mode Page 8 Core Components & Salient Features • Permanent Magnet Motor: a) Power required only to rotate & not for magnetizing of rotor; b) Can be started & stopped any number of times; c) High Efficiency even at part load • No Gear Box: No transmission loss due to direct drive & no lubrication required. • Variable Speed Drive for achieving high speed, smooth starts (reduced starting current) & energy efficient capacity control as part of the Blower package. • Air Foil bearing for high speed operation (used in Jet engines) • Oil Free air • Low Noise: 80 dB against 100 dB of PD blowers • Entire range is air-cooled & no need of water for cooling. Page 9 Comparison with PD Blowers Parameter PD Blower KTurbo Blower Aero Efficiency 55% 77% Drive Efficiency (Motor+Coupling+Invertor) 82% 92% Total Efficiency at 100% Load 45% 70% 22.5% 67% 250% Below 5% Overhaul Air Filters 5 Years Semipermanent Large Smaller 95-110 dB Below 80 dB Total Efficiency at 50% Load Starting Current compared to Rated Current Maintenance Life Foot Print Noise Level Page 10 PD Blowers Performance Page 11 PD Blowers Performance Typical model at 1800 RPM; Average total efficiency is 45% Page 12 PD Blowers Performance Page 13 Single Stage Turbo Blowers Performance Page 14 High Speed Turbo & PD Blower Performance Page 15 High Speed Turbo & PD Blower Performance Page 16 Aeration: Coca Cola (Korea) (Benefits with KTurbo ) 1) Discharge Temperature : Less than 20° C than Roots type. => Change Aerated water temperature: less than 3 ℃ than with Roots blower used earlier 2) Capacity control : Operating 1㎥/min => Protect for excessive aeration 3) Oil-less System => 100% oil-less air 4) Reduce energy consumption: more 40% (Before using roots blower) 5) Noise level : 82dB @ 1m (as against earlier 105dB with Roots blower) Page 17 SunRiver: North America installation • Before : 2 Units of 100hp Multi Stage • After: 1 Unit of TB100-0.8 (70% Operation) Page 18 Control Configuration for DO (Dissolved Oxygen) Intrinsic Feedback control HMI Display Flow Control DO data ( 4 ~ 20mA) ※ DO Sensor (Endress+Hauser Co.) Input: 0.015 ~ 60 ppm Output: 4 ~20mA Page 19 Schematic of KTurbo installation in WWTP plant Page 20 Picture of KTurbo installation in WWTP plant Page 21 Picture of KTurbo installation in WWTP plant Page 22 KTurbo blowers supplying air to WWTP plant Page 23 Construction of Single & Twin Turbo Blowers / Comp Intake Silencer Power In BOV Silencer Controls Inverter Page 24 2 Pole permanent magnet (SmCo) with high strength retaining ring High performance electric core H Class Insulation winding Discharge PM Motor & Impellers Scroll Stainless steel casted Impeller Radial airfoil bearing Intake Thrust disk & Thrust bearing Radial airfoil bearing Page 25 (1) Air foil bearings • • • • • Core Technologies Self-acting hydrodynamic float on air Bump foil acting as a spring The first generation – Axially & circumferentially uniform elastic support elements The second generation – Variable axial OR circumferential compliance characteristics The third generation – Foil support in axial, circumferential AND radial direction Page 26 History of Foil Bearings High Temp Solid Lubricant -PS304 ; NASA -KOROLON1350F ; MiTi Third Generation Bump (KTurbo) Multi-Pad Bump MoS2 Reversed Multi-Layer Teflon-S • Radial variation • Circumferential variation • Axial split/variation Simple Bump Multi-Leaf • MiTi have made major research • KTurbo has > 1000 units experiences • KTurbo has TC series High Capacity, High Speed, High Damping, High Temperature Page 27 Core Technologies (2) High-speed & high-power PM motor/driver • • PM motors – High-speed & high-power (50 hp ~ 600 hp / 20,000 rpm ~ 70,000 rpm) – High efficiency (> 95%) Sensor-less Inverters – Cost-effective – High efficiency (> 97%) Page 28 Why PM motor ? No magnetizing power is necessary Lower heat generation means less cooling loss. Smaller rotor means less friction loss No slip means high efficiency even at part load condition. Page 29 Efficiency of PM motor & Induction Motor Page 30 1. Stainless Steel Core Technologies (3) Features of KTurbo Impeller • SUS630, 17-4PH 2. Optimum Specific Speed • Maximum efficiency 3. Optimum back sweep angle • Maximum efficiency • High Rise to surge • Wide operating range 4. Splitter Blade • Larger flow capacity • Higher efficiency 5. Leaning • Higher structural strength Page 31 Built-in Flow Meter Bell mouth is more accurate than Orifice, because it needs only one sensor. P p Q 60 cd A P 1/ k k 1 k P p k 2 R T [m,K, sec, Pa, m 3 / min,Cd 0.99] 1 k 1 P Page 32 Discharge Duct Discharge pressure : P Discharge Temp : T2 Blow-off Valve Silencer Suction Flow rate dP : dP3 Suction Temp : T1 Filter Pressure Drop : dP1 Blower core Inverter Air Flow measuring Measurement System Inlet Reducer Air out Air in Impeller < Air Flow calculation, Q > Q ≈ Q (T1, Po , dP3) T1 + dP3 [Differential pressure] Page 33 HMI with touch screen Page 34 HMI: Main Screen Page 35 HMI: Operating Curves display Page 36 HMI: Data Logged every second CF memory is applied •Data logging every 1 sec, 1 min, 1hour •All event recording Page 37 HMI: On-line trend display CF memory is applied •Data logging every 1 sec, 1 min, 1hour •All event recording Page 38 Multi-Group Control CCR (Central Control Room) SCADA or DCS or PLC MCP1 TB #1 MCP2 TB #2 TB #3 TB #4 TB #1 TB #2 TB #3 TB #4 Page 39 Foundation Concrete pad Anchor bolting case-1 Anchor bolting case-2 Page 40 First stage Pre filter Secondary stage Medium filter Air Filters Filter Cover Motor Room Pre 85%@ 10㎛ 4-8 weeks Final 99%@ 10㎛ or 68%@2㎛ 5-12 months ΔP 21-44mmWTR Page 41 Customers Page 42 Customers Page 43 Thank You! Godrej & Boyce Mfg. Co. Ltd. Compressed Air Solutions Godrej | Electrical & Electronics Pirojshanagar, Vikhroli, Mumbai – 400079. India Tel.: +91-22-67962251 to 2255 Fax: +91-22-67961410 / 67961525 E-mails: kcp@godrej.com; jayraj@godrej.com; roshe@godrej.com; www.godrej-airsolutions.com Page 44