Micromouse_Lecture_1

advertisement

Encoders, Motors, Power, Mini Project #1

10/24/2014

We cannot use a simple voltage divider to

provide a consistent voltage source.

As the voltage from the battery decreases during

discharge, the output voltage will decrease!

In order to provide a

consistent source of potential

difference, we need to use

voltage regulators.

We will provide you with a 5V

regulator to connect to your

LiPo battery pack for Mini

Project #1.

Use capacitors to smooth out noise in your signal

Brushed and Brushless

Brushed motors take a DC signal.

Powers an inductor to rotate a magnet.

Increase the voltage and/or current -> Increase

the rotation speed.

Reverse the polarity of the input voltage ->

Reverse the rotation.

Most digital microcontrollers do not have an

analog signal output.

MCU’s output digital signals – either high or low.

So how do we control brushed motors?

Mimics an analog

voltage signal

Square wave with a

certain frequency

This can be used to

control the speed

of a motor

Speed is controlled by rapidly turning the

motor on and off

Turn the motor on for a greater fraction of the

time to make it rotate faster

The percent of time the PWM signal is on is the

duty cycle

0% duty cycle is same as off all the time; 100%

duty is same as on all the time

We cannot connect the MCU to the motor.

MCUs don’t provide enough current to power

motors.

Microcontrollers cannot invert the PWM signal to

rotate the motor in the other direction.

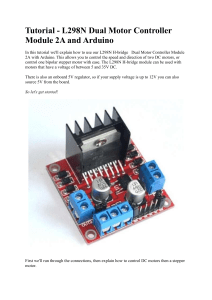

Have the PWM control a H-bridge

PWM controls transistors (think of them as

switches) that allows the battery to pour all its

current to the motor

Easy to control direction

Simplified diagram

Turn Left

Turn Right

Actual implementation for two motors

void turnLeft()

{

digitalWrite(1A, HIGH); //Right wheel

digitalWrite(2A, LOW); //Right wheel

digitalWrite(3A, LOW); //Left wheel

digitalWrite(4A, HIGH); //Left wheel

analogWrite(motorPwrR, 100);

analogWrite(motorPwrL, 100);

}

void turnRight()

{

digitalWrite(1A, LOW);

digitalWrite(2A, HIGH);

digitalWrite(3A, HIGH);

digitalWrite(4A, LOW);

analogWrite(motorPwrR, 100);

analogWrite(motorPwrL, 100);

}

Goal is the same as brushed

motors: rotate something

Mechanics is different

Multiple inductors attract and

repel the magnet

Has more control than DC motors

Controlling brushless motors are

more complicated

But fairly easy to do with IC

chips/software libraries

Helps you determine how far you have

travelled in the maze.

Rotary Encoders attached to wheels

Optical

Magnetic with Hall Effect Sensor

Light reflects off alternating bright or dark areas.

The detector determines when the light was shone

on it. (Mini Project #1 uses this).

Another method: LED shines through a teeth in a

disc to detector on other side.

Attach magnets to a disc

Use Hall effect sensors to detect the changing

magnetic field

Count the ticks to see how far the wheels have

turned

Encoders are constantly outputting data

Your MCU needs to read the values all the

time!

If your MCU is reading values 100% of the

time it can’t do anything useful!

Otherwise you are losing data, or must litter

your code with checks every few lines!

Not a good solution

Interrupts allow you to process data and then

go back to what you were doing

Interrupts allow you to process data and then

go back to what you were doing

“Yo imma let you finish, but this is some of

the most important data of ALL TIME”

An interrupt handler is a short function that

runs when an external event happens

Rest of the program pauses, and continues

after interrupt is done

From the perspective of each, the other

doesn’t exist*

*If your interrupt handler runs for too long (and

too often) it can choke your entire program!

Types of interrupts:

RISING

FALLING

CHANGE

LOW

HIGH

Arduino boards: only two interrupt pins

Teensy: all pins!

The volatile keyword:

Tells the compiler “this value can change at any

time!”

MCU will look up value in memory each time and

not an old value in a register

Anything your interrupt handler modifies should

be volatile, or you may get bugs!

Increment a counter and return (be fast)!

Don’t want to use this counter directly

If you accidentally overwrite it, you might not

be able to know how far you went!

Using good coding style you can prevent

mistakes!

But I’m too good to make such silly mistakes!

▪ Nonsense, we are all human, mistakes happen!

The static keyword:

Means “this variable/function can only be used in

this file only!”

Return value of counter with a function!

Now nobody from the outside can mess with it

directly!

Depends on how fast your encoders are

On super high resolution encoders, it may be

sufficient to track a single pin per encoder

On lower resolution encoders its better to

track both pins changing

Tracking a pin change gives you even “more”

resolution

If a wheel is on the edge between ticks, its

possible to get “false positives”

Demonstrate basic understanding of motor

control and encoders.

DUE DATE: 11/7/2014 SIGN UP EARLY

Parts (abridged)

Teensy 3.1

Motor

H-bridge

Encoders

Keep your eyes peeled for an email for when

the spec sheet for Mini Project #1 is up.

Do not hesitate joining a group you don’t

know to complete the Mini Projects. Make

friends!

Start early!