MYRRHADesignReview_Perrot - IPN

advertisement

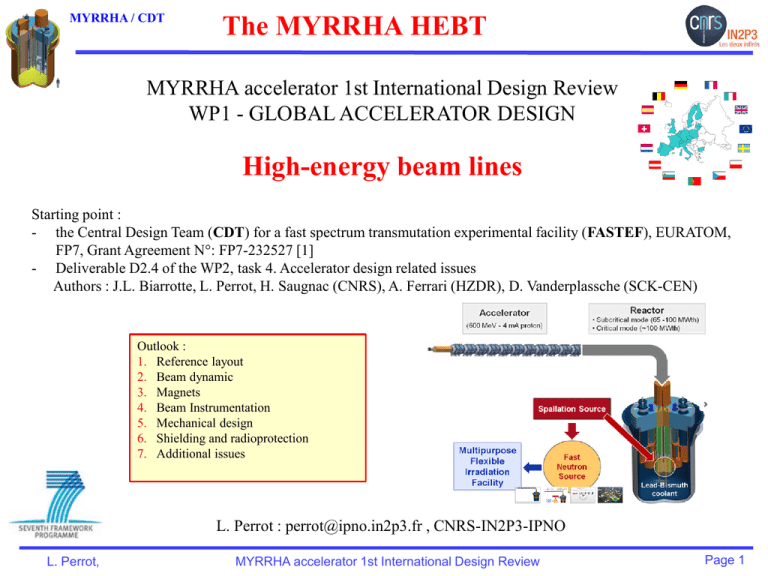

MYRRHA / CDT The MYRRHA HEBT MYRRHA accelerator 1st International Design Review WP1 - GLOBAL ACCELERATOR DESIGN High-energy beam lines Starting point : - the Central Design Team (CDT) for a fast spectrum transmutation experimental facility (FASTEF), EURATOM, FP7, Grant Agreement N°: FP7-232527 [1] - Deliverable D2.4 of the WP2, task 4. Accelerator design related issues Authors : J.L. Biarrotte, L. Perrot, H. Saugnac (CNRS), A. Ferrari (HZDR), D. Vanderplassche (SCK-CEN) Outlook : 1. Reference layout 2. Beam dynamic 3. Magnets 4. Beam Instrumentation 5. Mechanical design 6. Shielding and radioprotection 7. Additional issues L. Perrot : perrot@ipno.in2p3.fr , CNRS-IN2P3-IPNO L. Perrot, MYRRHA accelerator 1st International Design Review Page 1 MYRRHA / CDT Introduction The R&D program for the accelerator to MYRRHA ? The Central Design Team (CDT) for a fast spectrum transmutation experimental facility (FASTEF). It is the next step next after FP6 IP-EUROTRANS. European program : 2009-2012. “FASTEF is proposed to be designed to an advanced level for decision to embark for its construction at the horizon of 2012 with the following objectives: to demonstrate the ADS technology and the efficient transmutation of high level waste; to operate as a flexible irradiation facility; to contribute to the demonstration of the Lead Fast Reactor technology without jeopardising the above objectives” The Myrrha Accelerator eXperiment (MAX) : http://ipnweb.in2p3.fr/MAX/ “To feed its sub‐critical core with an external neutron source, the MYRRHA facility requires a powerful proton accelerator (600 MeV, 4 mA) operating in continuous mode, and above all featuring a very limited number of unforeseen beam interruptions. The MAX team, made up of accelerator and reliability experts from industries, universities and research organizations, has been set up to respond to these very specific twofold specifications.” CDT = R&D reactor+HEBT MAX = R&D accelerator We will be focus on the design of the final beam line which aims to transport the 600MeV, 4mA proton beam from the LINAC exit - up to the spallation target located inside the reactor core, - up to the 2.4MW beam dump L. Perrot, MYRRHA accelerator 1st International Design Review Page 2 MYRRHA / CDT 1. Reference layout HEBT : Transfer line from accelerator to the spallation target Prepare the beam spot requirements (shape, position, intensity and energy) Transfer line from accelerator with the beam-dump Provide a safe operation and maintenance Proton Beam specifications : 𝐸𝑝 = 600𝑀𝑒𝑉; stability to ±1% 𝐼𝑚𝑎𝑥 = 4𝑚𝐴 ; stability to ±2% 𝑃 = 2.4𝑀𝑊 Vertical injection «donut-shape» beam footprint on the spallation window with 85mm diameter and stability to ±10% Reliability : interruptions < 10 longer than 3sec. during a 3 months operation. The constraint is almost given by yhe accelerator L. Perrot, MYRRHA accelerator 1st International Design Review Page 3 MYRRHA / CDT 1. Reference layout From EUROTRANS [2] project, it was choosen the second conceptual design (less components and lowest high of the reactor building [3]. General layout compatible with reactor building produced by Empresarios Agrupados, CDT WP3 (“Plant requirements”) [4] 90° bending magnet Pole-face rot.=26.565° Beam line to reactor: layout FROZEN Scanning device 24m Beam line to dump: not fully finish 45° rectangular bending magnet Quad triplet 26.5m 30m Reactor -45° rectangular bending magnet Dump Object point 40m Matching 38m downstream the LINAC tunnel Z=-2.5m ground L. Perrot, 15m Quad triplet 20° bending magnet +2 quadrupoles MYRRHA accelerator 1st International Design Review Page 4 MYRRHA / CDT 1. Reference layout 14 quadrupoles (L=0.5m, ⌀100mm, 3T/m max) 2 dipoles 45° (ρ=3.2m, gap 100mm, 22.5° edges) 1 dipole 90° (idem, 26.56° edges, radiation-hard) 90° bending magnet Pole-face rot.=26.565° 18 DC steerers (L=0.3m, 150G max), beam orbit correction 2 AC steerers (L=0.3m, 150G max) Scanning device 24m Pipe aperture = 100mm, in dipole=95mm Diagnostics boxes (in green), see later Beam losses have to be < 1nA/m like SNS [5] for components activation and safe maintenance 45° rectangular bending magnet Quad triplet Vacuum < 10-7mbar 26.5m At the target window mbar must be achieve (beam losses ~0.05nA/m) 10-4 30m In case of incident with the beam in the HEBT : Tswitch-off<50ms. Reactor -45° rectangular bending magnet Dump Object point 40m Matching 38m downstream the LINAC tunnel Z=-2.5m ground L. Perrot, 15m Quad triplet Diagnostics 20° bending magnet +2 quadrupoles MYRRHA accelerator 1st International Design Review Page 5 MYRRHA / CDT 2. Beam dynamic studies By construction, the line: is achromatic at 1st order (position & divergence on target independent of beam energy) : T16=T26=0 from LINAC to target has telescopic properties at 1st order (image size on target = 9 x object size at point 0) : T11=T33=9 between object point and target. Target beam size is control by the beam size at the matching object point 0. Donut-shape beam footprint achieved with the AC scanning magnets. Circular movement with few tens of Hz No focusing during the last 25m (reactor hall) O L. Perrot, MYRRHA accelerator 1st International Design Review Page 6 MYRRHA / CDT 2. Beam dynamic studies 600MeV Protons beam envelopes at 3RMS, using TraceWin Code [6] Normalized emittances: ex=0.242, ey=0.234, ez=0.291 p.mm.mard Horizontal plane in blue, vertical plane in red O Without scanning Beam phase space at the LINAC exit L. Perrot, T46 vertical dispersion Beam phase space on the spallation window Without scanning : RMSX,Y=9mm MYRRHA accelerator 1st International Design Review Page 7 MYRRHA / CDT 2. Beam dynamic studies Target aspects: Why do you need the beam scanning ? Reactor The scanning devices not yet design -- Horizontal Scanning 25m Beam scanning must be done in order to protect the Pb-Bi target window But : No space is involved inside the reactor hall (no quad, no instrumentation) Safety do not permit to install the scanning device after the last 90° dipole Donut shape is impose by the Pb-Bi liquid target cooling Maximum beam scanning amplitude is fixed by target windows + last 2 meters beam pipe penetration inside the reactor core Scanning speed depend almost to target windows and Pb-Bi speed cooling Need to 2 scanning dipoles located before the last 90° vertical dipole the maximum amplitude have to be less than 150G with frequency close to 100Hz (not yet frozen) -- Vertical 13kW/2.4MW Beam phase space on target with scanning Target window zone L. Perrot, MYRRHA accelerator 1st International Design Review Page 8 MYRRHA / CDT 2. Beam dynamic studies Impact of a energy jitter The beam target foot-print have to be not sensitive to primary beam energy variation, which is ensure by the first order achromatic line But between dipole, beam shift centroide is dependant to T16. Therefore, dedicated instrumentation have to be install like collimators, ring losses or segmented collimators. X Plane Collimators / rings Y Plane Collimators / rings Effect of a 0.5% beam shift energy (3MeV / 600MeV) “donut-shape” footprint Use to a raster magnets on X and Y, using a (possibly redundant) set of fast steering magnets operated at frequencies of several tens of Hz Central trajectory is continuously deviate. The ±9 mm RMS beam spot on target is moved around the window centre in a circular pattern of radius 20 mm. Octupole expander solution is not feasible (see next slide) L. Perrot, Target window zone Beam spot movement MYRRHA accelerator 1st International Design Review Page 9 MYRRHA / CDT 2. Beam dynamic studies Multipole beam expander ? Homogeneous beam density distribution can also be performed using a set of octupole magnets in front of the target: The first set of octupoles (1 or 2) produces a square homogeneous footprint - An additional turned octupole transforms the square in circle 60mm 120mm - This is a beautiful solution, but several drawbacks: - Produces a lot of beam halo => has to be located near the final target 1. Impossible in our case 2. Tested location: upstream. Unmanageable (unless a possible 2nd order O-I system ...?) - Extremely sensitive to any beam misalignment or beam size variation => For MYRRHA, it seems extremely complicated (if not impossible) to implement L. Perrot, MYRRHA accelerator 1st International Design Review Page 10 MYRRHA / CDT 2. Beam dynamic studies O Tuning method : 1. Set the magnets to their theoretical value, & send a very low duty cycle beam (10 -4) 2. Adjust DC steerers for orbit correction (alignment) 3. Adjust QP1-3 => tune beam waist on 0 w/ desired size (1mm rms), using 3 transverse beam profil detectors 4. Adjust QP7-13 => achromaticity optimization using beam position monitor, target optical diagnostic. 5. Adjust QP 4-6 => re-adjust desired beam size on target (9mm rms), check telescopic properties 6. Recheck alignment & switch on + tune scanning device for obtain the “donut-shape” on target 7. Increase step by step the beam duty cycle (chopper in the LEBT) L. Perrot, MYRRHA accelerator 1st International Design Review Page 11 MYRRHA / CDT 2. Beam dynamic studies Statistical error study • Static errors are randomly applied to: - Magnets (displacement, field error) - Input beam (position, divergence, energy, emittance, intensity, mismatch) • The beam tuning procedure is simulated step by step: - static errors are corrected when possible - errors on beam diagnostics measurements are taken into account • Dynamic errors (mechanical vibrations, stability... ) are then randomly applied: - These transient errors are not corrected - Applied to magnets (displacement, field error) & input beam (position, divergence, energy, emittance, intensity, mismatch) • Iteration is performed to get good statistics: - 100 different line configurations - each one with a tracking involving 105 macro-particles L. Perrot, MYRRHA accelerator 1st International Design Review Page 12 MYRRHA / CDT 2. Beam dynamic studies Error calculations 1. Nominal 99% envelopes without errors, without scanning L. Perrot, MYRRHA accelerator 1st International Design Review Page 13 MYRRHA / CDT 2. Beam dynamic studies Error calculations 2. 99% envelopes with UNCORRECTED static errors (random distribution) , without scanning L. Perrot, MYRRHA accelerator 1st International Design Review Page 14 MYRRHA / CDT 2. Beam dynamic studies Error calculations 3. 99% envelopes with CORRECTED static errors (same random distribution) , without scanning L. Perrot, MYRRHA accelerator 1st International Design Review Page 15 MYRRHA / CDT 2. Beam dynamic studies Error calculations 4. 99% envelopes with CORRECTED static errors + uncorrected dynamic errors, without scanning L. Perrot, MYRRHA accelerator 1st International Design Review Page 16 MYRRHA / CDT 2. Beam dynamic studies Error calculations: beam losses Possible losses on collimator: Losses on final tube: - Min = 0, Max = 29kW - Min = 0.5kW, Max = 110kW - Mean = 0.3 kW, RMS = 3kW - Mean = 15 kW, RMS = 14kW => Losses in 1% cases from 107 particles L. Perrot, MYRRHA accelerator 1st International Design Review Page 17 MYRRHA / CDT 2. Beam dynamic studies Error calculations: trajectories Mean orbit (X) Mean orbit (Y) RMS orbit (X) RMS orbit (Y) This error study is quite insufficient to get to definitive conclusions, but gives already good orders of magnitude for the required tolerances and a good feeling of the general situation. We need a end-to-end accelerator errors calculation L. Perrot, MYRRHA accelerator 1st International Design Review Page 18 MYRRHA / CDT 2. Beam dynamic studies Error calculations: target footprint : fluctuations are considered acceptable X rms size Footprint (log scale) L. Perrot, Y rms size Footprint (linear scale) MYRRHA accelerator 1st International Design Review Page 19 MYRRHA / CDT 2. Beam dynamic studies Error calculations: sensitivity • • Errors impacting the orbit excursion through the line (i.e. beam losses) 1. Beam energy jitter: ±1MeV => 5 mm rms deviation (DYNAMIC) 2. BPM precision: ±0.5mm => 2 mm rms deviation (STATIC) 3. Magnets alignement: ±0.3mm => 1 mm rms deviation (STATIC) 4. Dipole field stability: ±2.10-5 => 0.5mm rms deviation (DYNAMIC) Errors impacting the position on target 1. Input beam divergence jitter: ±0.01mrad => 0.7mm rms (DYNAMIC) 2. Input beam position jitter: ±0.1mm => 0.6mm rms (DYNAMIC) 3. Dipole field stability: ±2.10-5 => 0.5mm rms (DYNAMIC) 4. Quadrupoles mechanical vibrations: ±10mm => 0.4mm rms (DYNAMIC) 5. Beam energy jitter: ±1MeV => 0.3mm rms deviation (DYNAMIC) 6. Dipole mechanical vibration (Y): ±10mm => 0.2mm rms (DYNAMIC) • Errors impacting the spot size on target 1. Quadrupoles gradient stability: ±10-3 => 0.15mm rms (DYNAMIC) 2. Beam energy jitter: ±1MeV => 0.1mm rms (DYNAMIC) 3. Beam profiler precision measurement: ±0.5mm => 0.1mm rms (STATIC) L. Perrot, MYRRHA accelerator 1st International Design Review Page 20 MYRRHA / CDT 2. Beam dynamic studies Beam line to dump Tuning the beam line from p-source up to HEBT (commissioning, tuning & check) • Present layout of the line: 3s beam envelops 20° dipole to avoid neutron back streaming & ease the maintenance 2 quadrupoles to defocus beam on dump with 210mm diameter • 240mm larger beam vacuum pipe along the final 6m Beam dump design Preliminary design from the 1 MW PSI proton dump (larger) Required shielding, preliminary study performed Detailed mechanical & thermal assessments to be done 15m Power losses = 2-3kW/cm² 600MeV protons range in Copper = 25cm L. Perrot, MYRRHA accelerator 1st International Design Review Page 21 MYRRHA / CDT 3. Magnets Quadrupoles 2 series of quadrupoles : 14 for the beam main HEBT line (Q-50), 2 for the beam-dump line (Q-100) Quadrupole design & size choose for minimize fringe fields & others higher orders contribution Current density from 2 up to 10 A/mm² Water cooling < 10 bars Radiation-hard materials (low carbon steel) Design can be closed to the SNS quadrupoles L. Perrot, MYRRHA accelerator 1st International Design Review Page 22 MYRRHA / CDT 3. Magnets Dipoles 600MeV protons => Br=4 Tm => Dipole radius = 3.2m 4 magnets 3 angles of deviation : 20° (beam-dump line), 45° (x2) and 90° (up to reactor) C-type magnets (except for 20° magnet) Reliability have to be taking into account (coils design) Radiation-hard materials especially for 90° and 20° magnet POISSON calculation of a basic 90° dipole magnet for MYRRHA/FASTEF. 2. 10-4 Field homogeneity is achievable in the “good field region”. Design can be closed to the CNAO cancer therapy facility in Italy [7] L. Perrot, MYRRHA accelerator 1st International Design Review Page 23 MYRRHA / CDT 3. Magnets Steering and scanning magnets Steering magnets are used for the orbit correction DC power supply Number = 18 (9 for horizontal plane, 9 for vertical plane) Magnetic length = 30cm Aperture = 110mm Working range : -500G<B<500G RMS operating value = 85G Orbit correction DC steerer used at the CNAO facility (Italy) Scanning magnet : produce the beam «donut-shape» on the Pb-Bi window AC power supply Number = 2 (X&Y) or 4 for redundancy Magnetic length = 30cm Aperture = 110mm Working range = -150G<B<150G Frequency : to be defined (~few hundreds of Hertz) Prototype of a 500 Hz 500G scanner magnet developed at Los Alamos for the APT project [8] L. Perrot, MYRRHA accelerator 1st International Design Review Page 24 MYRRHA / CDT 4. Beam Instrumentation Overview Beam diagnostics and control systems will be deployed all along the final beam transport line in order to tune the beam, maintain normal operation according to specifications, and protect the beam line equipments in case of malfunctioning. beam intensity measurement current monitors (accuracy <1%), beam loss monitors for trigger interlocks for beam switch off (DT<1ms) Optical system (VIMOS like system at PSI [9] for beam footprint on target monitor and survey. For MYRRHA, need a dedicated R&D Couple of halo scrappers and wire profilers should also be used if possible (this will probably not be the case) in the last straight section for redundancy. At the exit of the 90° bending magnet, halo monitors for checking the beam center and size are roughly correct. Standard beam diagnostics (position and size) Diagnostics type and usage for beam transfer line Main beam diagnostic devices along the HEBT L. Perrot, MYRRHA accelerator 1st International Design Review Page 25 MYRRHA / CDT Few details PSI BPM: capacitive pick-ups or magnetic loops symmetrically arranged in the pipe wall 4. Beam Instrumentation Beam profiler : electron secondary emission or wire scanner Energy : ToF technique = 3 pick-up capacitive electrodes SPIRAL2 SPIRAL2 L=20 needed to obtain (𝜕𝐸/𝐸)<10-3 PSI Current : fundamental for the reactor monitoring TM01-mode coaxial resonator (aluminum, with a 10μm coating layer of silver to improve the electrical conductivity) DCCT : average beam current ACCT : single bunch monitoring Halo & Losses : tuning phase + safety (machine protection) : <1nA/m loss level Loss Ring : particle interactions induce currents, size adapted to the beam size, material Cu, Ni, Mo or C, cooling may be necessary, sub-sections can be useful BLM : detectors implantation around the beam tube. 6 along the HEBT to ensure the 1nA/m loss level Target monitoring : measure the beam size + position close the target. Crucial & challenging measurement for MYRRHA Beam have to be monitored continuously (deviation from tight reference values and peak power density feed-back). Optical technic like VIMOS (at SINQ - PSI) or TIS (SNS): Thermal incandescence Cr/Al2O3 fluorescence Optical transition radiation (OTR) He fluorescence (from fill gaz in line) - SPIRAL2 PSI SPIRAL2 L. Perrot, PSI ionisation chamber MYRRHA accelerator 1st International Design Review Page 26 MYRRHA / CDT 5. Mechanical design First conceptual design of the whole high energy part of the line and its integration inside the reactor building. We take into account the design of the reactor and the definition of the building Separated in different parts, due to the various security constraints Safety requirements have an important impact on the building design, the accessibility and the mounting/dismounting procedures L. Perrot, MYRRHA accelerator 1st International Design Review Page 27 MYRRHA / CDT 5. Mechanical design Part 1 : Part 2 : - - beam axis =+1.5m to the floor Corridor 5m large Beam line not centered (3m right) for accessibility No crane alignment done with “Laser Tracker” 45° inclined line, length = 30m Part of the beam dump casemate in this hall Crane of 50 tons capacity BD line in a 20° deviation. Reduction of the neutrons backscattering and better access for the handling Part 3 : - Tunnel of 22 metres long, 6.5 metres large and 10 metres height - Crane of 50 tons capability, common with part 2 10-7 mbar vacuum specification (not yet study) : Vacuum components and fittings will be ConFlat® type Turbo-molecular pumping group with 200 l/s capacity. 1 pump placed each 3m. Each component subjected to alignment adjustments (magnets, diagnostic boxes, collimators…) has to be installed using bellows allowing enough longitudinal and lateral displacement. L. Perrot, MYRRHA accelerator 1st International Design Review Page 28 MYRRHA / CDT 5. Mechanical design Part 4 : 90° magnet zone - Backscattered neutrons from reactor => hot cell probably - Need to specific material, remote handling and nuclear waste capabilities - Pumping system of the vertical line & 90° dipole will be in this section (200l/s turbo + 16m3/h primary) - 50 tons crane - Fast valve before and after concrete wall - Vertical port for beam foot-print detection system and/or neutron dump coming from reactor. Part 5 : Beam line inside the reactor hall - High activation zone. Need complete isolation, full remote and lateral handling. Less active components must be chosen Reactor access imposed to dismount the line No pumping system in this section 3 parts for the line Alignment is a major concern Vacuum at the spallation window fixed to 10-4mbar 2 Fast valves (15ms closing time) for protection against the window breaking and accelerator failure (like cryogenic accidents) L. Perrot, MYRRHA accelerator 1st International Design Review Page 29 MYRRHA / CDT 5. Mechanical design Part 6 : Beam line casemate: Conceptual design A 2.4 MW, full power beam dump, based on the 1.2 MW PSI proton beam dump, is foreseen to allow the commissioning of the MYRRHA accelerator independently from the reactor. The conceptual design of the MYRRHA beam-dump is taken from the 1.2MW PSI existing dump [10]. Dump is handled from the top using the common 50 tons crane (part 2 & 3). Due to the 20° deviation. It is not necessary to dismount the line. Beam power deposition on 6 blocks (PSI=4 blocks), length=3m Material : Copper but need to be optimized considering the high level of activation. High density carbon fiber surrounded by stainless steel can by a useful alternative The beam dump casemate=Hot cell 15 m deep, concrete wall to 5m thickness, 20 tons crane 10 m 30 m 9m L. Perrot, Structure of the 1.2 MW PSI proton beam dump MYRRHA accelerator 1st International Design Review Page 30 MYRRHA / CDT 6. Shielding and radioprotection The goal of the shielding design is to guarantee that, under normal operational conditions, the added integrated dose to anybody working around the FASTEF/MYRRHA accelerator is extremely small, i.e. comparable or smaller than the natural background. To reach this goal one must rely on: the use of conservative beam loss assumptions; the use of a conservative shielding model; the assumption of an occupancy factor = 1, that means 2000 hours/year occupancy close to the outer shielding wall (at the maximum dose rates). First evaluations have been performed during the PDS-XADS project, considering a continuous 1 nA/m proton loss at 600 MeV. This is equivalent to a mean beam loss level of about 0.6 W/m. Required concrete/earth combined thickness at 600 MeV to reach the 0.5 μSv/h dose rate level. For 600MeV protons Shielding issues in the reactor building impact strongly on the 90° dipole shielding. Concrete walls and roofs up to 5 m thick would therefore be needed to reach the 0.5 μSv/h dose rate outside the facility. Shielding issues around the beam dump : the BD design must satisfy the shielding requirements & minimize the backscattered neutron & minimize the BD activation L. Perrot, MYRRHA accelerator 1st International Design Review Page 31 MYRRHA / CDT 6. Shielding and radioprotection Activation Main problems : Activation of the elements devoted to the beam absorption (beam dump) Activation of the material of the line due to beam losses Calculations preformed using the FLUKA MonteCarlo code [11] which give : - Particle fluences - Ambient dose equivalent - Time evolution of the activation products (build-up and decay of radionuclides) Calculation on various “targets” (Carbon, Copper, AlSl-316L, Aluminium, Iron) Residual (in μSv/h) around 100 m beamline, for two representative cooling times after a short and a long-term irradiation. Neutron fluence (n/cm2 per beam proton) in and around the target Residual dose rate around the carbon target, at different cooling times L. Perrot, MYRRHA accelerator 1st International Design Review Page 32 MYRRHA / CDT 6. Shielding and radioprotection Optimisation of the beam dump zone Full absorption of the 600MeV protons beam We have already presented a structure closed to the 1.2MW PSI beam-dump. Advantage of the know how but secondary neutrons and activation are very high. We have explore an alternative solution for the safety studies with a soft material as dump core (Carbon) surrounded by a high-Z shielding structure (stainless steel). Smaller neutron yield and less activation problems. Dose rate (in mSv/h) Neutron fluence (n/cm2 per primary proton) in the dump concrete cage of the dump casemate Copper core Copper core Carbon core + stainless steel Carbon core + stainless steel The soft Carbon core solution is clearly a good candidate Beam dynamic and mechanical integration not yet study L. Perrot, MYRRHA accelerator 1st International Design Review Page 33 MYRRHA / CDT 7. Additional issues Adaptation of the final layout The building detailed definition is still in progress, and will probably keep moving slightly until the start of the MYRRHA construction. It is therefore important to ensure that the beam line layout will be able to adapt to these changes as much as possible without major consequences. Possible beam line adaptations in the case of a reactor height increase Study of a radiatively cooled cold window Vacuum protection of the final beam line in case of a target window failure Third passive protection in addition to the fast valves : use a thin metallic foil able to sustain high temperature gradients without perturbing too much the beam optics. In existing (low-power) accelerators, titanium foils of a few hundreds of μm are typically used. Study of a 100mm diameter 400mm thick Titanium using LISE++ code [12]. Eloss=0.33MeV, Ploss=1.3kW => fusion of the window (need to have a 30cm beam size (including halo) which is not reasonable. Using a cold window seems to be quite unrealistic Study of a water cooled cold window J-PARC ESS prototype SNS/JPARC : Inconel 718 (1.5 to 2 mm thickness) separated by a 1.6 to 3 mm gap in which water flows (at typically 10 bars) ESS project : Aluminum tube cooled by Helium at 40 bars Apply to our case with the SNS/JPARC solution, Ploss=27kW Beam emittance increase by a factor 10 (sx’,y’ from 0.4mrad up to 4mrad) => not compatible with a window location at 25m up to the spallation window Activation of this cold window Need to be located very near the target itself SNS feedback can be an extremely important issue for MYRRHA L. Perrot, MYRRHA accelerator 1st International Design Review Page 34 MYRRHA / CDT Conclusion HEBT for the MYRRHA project A beam line from the LINAC up to the reactor The goal of the MYRRHA/FASTEF final high‐energy beam line is to safely inject the proton beam onto the spallation target located inside the reactor Consolidated design of the beam line to reactor achieved AC steering magnets are preferred for the beam scanning Error study shows very robust behavior (sensitivity in the X-plane may be optimised) Need start-to-end error studies Near-target optical device appears to be mandatory to be able to correctly tune and monitor the beam shape on target. First detailed mechanical design is described for each part of the line First shielding and activation calculations have been performed Beam dump design on-going, need to be study in details (structure…) L. Perrot, MYRRHA accelerator 1st International Design Review Page 35 MYRRHA / CDT 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. References J.L. Biarrotte, L. Perrot, H. Saugnac (CNRS), A. Ferrari (HZDR), D Vanderplassche (SCK-CEN), Accelerator design related issues, February 2012, deliverable D2.4 of the WP2 task 4 to the CDT project, Seventh Framework Program EURATOM, Grant Agreement N° FP7-232527 J-L. Biarrotte et al. – “Accelerator design, performances, costs & associated road-map”, Deliverable (D1.74) of the EUROTRANS project, March 2010. L. Mansini – Minutes of the CDT WP2 3rd technical meeting, Mol, 14-15 November 2010. Drawings package N° 092-204 by Empresarios Agrupados. J. Galambos – “Operational experience with high power beams at the SNS superconducting linac”, Proc. of the LINAC’2008 conference, Victoria, Canada. TraceWin Code : http://irfu.cea.fr/Sacm/logiciels/index.php W. Beeckman et al, “Magnetic design improvement and construction of the large 90° bending magnet of the vertical beam delivery line of CNAO”, Proc. Of the EPAC 2008 conference, Genoa, Italy. M.E. Schuze et al., “Testing of a Raster Magnet System for Expanding the APT Proton Beam”, Proc. of the PAC’99 conference, New York, USA. K. Thomsen, “VIMOS beam monitoring for SINQ”, Proc. of the DIPAC’2009 workshop, Basel, Switzerland. See http://aea.web.psi.ch/Urs_Rohrer/MyWeb/pkanal.htm A. Ferrari, P. Sala, A. Fassò, J.Ranft, “FLUKA: A multi-particle transport code”, CERN-2005-10 (2005), INFN/TC_05/11, SLAC-R-773. O.B. Tarasov, D. Bazin, “LISE++: Radioactive beam production with in-flight separators”, NIM B 266 (2008) 4657–4664. L. Perrot, MYRRHA accelerator 1st International Design Review Page 36