Harrison Building Presentation

advertisement

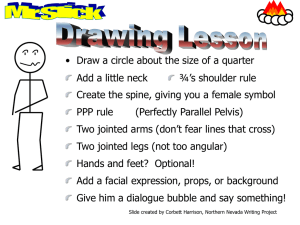

Harrison Elementary A look at some concerns. Harrison History Harrison is a 21 classroom, 43,835 square foot school built in 1948 on 7.83 acres of land. The building has had additions in 1951, 1956,1967,1969,1974 and 1986. The construction of the building is wood framing, concrete block, clay brick and a considerable amount of glass block. Roofing Materials are a combination of asphalt shingles and built up asphalt roofing on flat areas. Aged clay brick and failing mortar. The combination of aged clay bricks and failing mortar are of great concern in the event of any seismic event. The aged glass block walls have the same negative affect on the collapse potential in a seismic event. In 2005 The Oregon Department of Geology and Mineral Industries conducted a study under Senate Bill 2 called the “Statewide Seismic Needs Assessment Project” On a DOGAMI scale of 6.7 (low risk) to -1.5 (very high risk) Harrison’s collapse potential score was 0.9 placing it in the High potential category. FEMA then rated the score as “Inadequate”. The minimum score for an “Adequate” rating would be 2.1. Roofing Conditions. Harrison is overdue for a complete tear off and reroof. Cost estimates for the 365,000 square feet of shingled areas is approximately $145,000.00. Cost estimates for built up asphalt tear off and replacement is $95,000.00. Cost estimates for 20% sheeting replacement is $11,000.00. Estimated total is $251,000.00 This number would grow if more than 20% sheeting damage or any structural framing damage is found. In addition any asbestos found in core sampling of flat roof sections would add the cost of abatement. A.D.A compliance. Harrison’s restroom facilities have no accommodation for individuals bound to a wheel chair. Remodeling to address this issue are costly and limited due to the current design and floor plan. In addition to the lack of A.D.A compliant bathroom facilities there are no provisions for disabled parking on site. The current urinal systems use very old tank and float continual flow flushing. This design wastes a considerable amount of water and repair parts are unavailable. Again, remodeling would be very costly as the plumbing infrastructure is very old and weak. Domestic water piping. The domestic hot and cold water at Harrison flows through galvanized iron piping. The vast majority of this piping is compromised both in volume and pressure due to internal corrosion and rust. Where accessible we have removed sections of ¾” I.D pipe that has as little as ¼” of an opening for water to flow in. Measures to replace this piping would be extremely costly and hard to quote due to lack of accessibility and close proximity to asbestos wrapped steam piping. H.V.A.C At Harrison Elementary. Accessibility Woes. The majority of steam fan/coil units at Harrison are accessed by ladder and a small opening as shown here. The hard part happens after you crawl through the opening and begin your way to the unit on hands and knees across roof trusses. Typical Fan/Coil Unit. This is what a typical classroom fan/coil unit looks like. This is close to a crawl opening at 50’ away. Some of these units are over 100’ from the small access point. Maintenance is continual and bringing tools and repair parts is a nightmare. This equipment is original to 1948. It is very inefficient, does not offer adequate indoor air quality and is almost impossible to deliver consistent comfort to students and staff. The control system is an antiquated pneumatic infrastructure that requires air pressure to actuate steam valves and dampers. The repair parts are hard to find when possible and very expensive when you do find them. Above Kitchen Crawl. Median crawl. Pneumatic Controls This is a typical set of duct temperature pneumatic sensors. They are very antiquated, inaccurate and expensive. Please note the asbestos mat insulation they are mounted over. Again extremely expensive abatement costs play into any upgrades. Air Conditioning Harrison is challenged in many ways due to the ever increasing need to upgrade systems to accommodate technology. Computers and servers reject a lot of heat. This heat must be removed to keep instructional areas remotely comfortable. The 5 residential type air conditioners on the roof range in age from 20 to 35 years old and are very inadequate. Replacement of the H.V.A.C system at Harrison would be challenging at best with a price tag in the 1.5 million dollar range not including abatement of asbestos or costly upgrades to the electrical system that will be covered later in this presentation. Single pane uninsulated windows. Inefficiency and rotten wood The single pane windows throughout Harrison offer little to no insulating value and the wood framing that encloses them is failing due to rot in most areas. Replacement of these windows is expensive due to labor, purchase of insulated units and abatement of asbestos glazing. Exterior Doors Harrison’s exterior double door sets have broken down to the point of needing replacement. There are seven door sets at a total estimated replacement cost of $63,000.00 Excluding any structural damage found upon removal of existing doors. Fire and Security protection. This is a picture of the current fire panel at Harrison. It covers a very limited area and is audible only. Fire suppression (sprinklers) can only be found in the boiler room. The Security system at Harrison only covers the office area and Kitchen. Besides being limited it is a non addressable system and like the rest of the District it lacks cameras. Installing adequate systems at this site would be in the Hundreds of thousands of dollars due to cost of devices and complete upgrade of the water supply to the building to accommodate fire suppression piping. Unsafe walkways and sidewalks Deteriorating asphalt and concrete surfaces. Both asphalt and concrete surfaces for walkways, sidewalks and playground areas are in dire need of removal and replacement. Again these are large areas with a large capitol project price tag. Electrical Systems. Maximum Capacity. The main power distribution and sub panel infrastructure at Harrison are overtaxed, outdated and woefully insufficient. Most classrooms share a single 20amp outlet circuit with another classroom and cannot support current technology demands let alone any chance for smart boards or other new cutting edge tools available to keep our students up to date with ever advancing technology. All options for adequate H.V.A.C systems would also require significant upgrades to the electrical system that could easily exceed the million dollar mark. Harrison Kitchen. Busting at the seams. Tight spaces and extremely aged equipment. None of the walkways in Harrisons kitchen are wide enough for two people to pass by each other. The steam equipment is unusable due to safety concerns and cost of repair/replacement. Two of the four ovens cannot be used for the same reasons. The maintenance team is touch up painting on a regular basis to keep the wood cabinets and shelving system in compliance with Health Code. Refrigeration Equipment. Iced freon supply lines. Broken down cabinet. Last Leg! The walk in freezer for Harrison’s kitchen is breathing its last breath. The insulation has broken down inside the walls. The holes you see are to let condensed water out. The result of poor insulation is a unit that never shuts off and wastes a large amount of electricity to keep product frozen. Replacement of this unit to accommodate current need would be about $70,000.00 excluding electrical upgrades, a new slab and sidewalk. Dish washing room\ closet. The dish washing room is essentially a closet with extremely minimal room to work. The dishwasher itself is in need of replacement and there is no room for expansion of this area. Kitchen venting system. Exhaust and makeup air. The system to remove steam and smoke from the kitchen area is original equipment and we recently had to have parts manufactured to repair it due to unavailability of parts. The same amount of air removed from the space should be replaced (made up) with heated air and is not due to the make up air unit being removed in the early 90’s. Replacement of the make up air unit would be about $19,500.00 excluding abatement and steam pipe repair. Drainage infrastructure. The current downspout and surface water drainage system is concrete no hub tile pipe. Tree roots, pipe decay and settling have rendered the system inadequate causing area flooding and unsafe conditions. Renovation of this system would require considerable excavation and removal of both asphalt and concrete to expose areas to be replaced. Flooring. Classroom carpet. Asbestos floor tile. Flooring woes. Classroom carpets at Harrison are in need of replacement due to age and condition. At approximately $6000.00 per classroom for antimicrobial commercial grade carpet this is about a $150,000.00 project including the Library. All hallways, the multi purpose room, wet areas in classrooms and administration areas that are hard surface are covered with asbestos floor tile. They do need replaced but abatement costs would be astronomical. Harrison multi purpose room. Not enough space. • The multi purpose room at Harrison is used for a cafeteria, gymnasium and all afterschool events. Folding cafeteria tables are set up and taken down twice daily and moved out into the hall to accommodate breakfast, lunch and physical education classes. • After school programs are cramped and physically uncomfortable due to lack of climate control and limited space. Outside Play Shed. The outside play shed is the only area for any physical activity on rainy days after breakfast and lunch. The asphalt surface is very slick when wet and the beam structure has several areas with extensive rot. Honestly a separate heated gymnasium has been a valid need for some time. Harrison Parking and drop off area. Here is a shot of the parking for Harrison. You will notice there is none. Student pick up and drop off is a little crazy due to no safe areas for parents or busses to get off of the side of 10th street. As mentioned previously there are no provisions for handicap parking.