Chapter 8 - Denali Rx

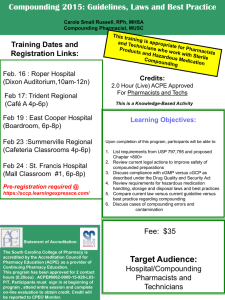

advertisement

Chapter 8 Nonsterile Pharmaceutical Compounding © Paradigm Publishing, Inc. 1 The Need for Compounding • Before large-scale pharmaceutical manufacturing, pharmacists compounded most prescriptions. • Compounding is still necessary, but most chain pharmacies do not have the time, space, or expertise for compounding. • A growing number of independent pharmacies are specializing in compounding service. © Paradigm Publishing, Inc. 2 Terms to Remember compounding the process of preparing a prescribed medication for an individual patient from bulk ingredients created by a pharmacist in order to treat a specified medical condition according to a prescription by a licensed prescriber © Paradigm Publishing, Inc. 3 The Need for Compounding • Sterile compounding • Nonsterile compounding © Paradigm Publishing, Inc. 4 Sterile Compounding • Includes preparation of injectable medications • Done mostly in hospital pharmacies • Requires special – Equipment – Workspaces – Expertise © Paradigm Publishing, Inc. 5 Terms to Remember sterile compounding the preparation of a parenteral product in the hospital, home healthcare, nuclear, or community pharmacy setting; an example is an intravenous antibiotic © Paradigm Publishing, Inc. 6 Terms to Remember nonsterile compounding the preparation of a medication, in an appropriate quantity and dosage form, from several pharmaceutical ingredients in response to a prescription written by a physician, such as tablets, capsules, ointments, or creams; sometimes referred to as extemporaneous compounding © Paradigm Publishing, Inc. 7 Nonsterile Compounding • There are many examples of nonsterile compounding preparations: – Solutions and suspensions – Ointments and creams – Suppositories and capsules • Many dermatologists and gynecologists prefer to individualize prescriptions for their patients. • Pharmacists also compound prescriptions from dentists and veterinarians. © Paradigm Publishing, Inc. 8 Nonsterile Compounding Why compound? – If prescription calls for a smaller dose than is commercially available – If a patient requires alternative dosage form • Cannot swallow pills • Oral medication may harm stomach • May be allergic to preservatives or colorings © Paradigm Publishing, Inc. 9 Nonsterile Compounding • Solution – liquid dosage form – Active ingredient (solute) dissolved in a solution (solvent), which may be waterbased or alcohol-based • Suspension – active ingredient not dissolved but dispersed – Has a tendency to settle – Suspending agent prevents settling © Paradigm Publishing, Inc. 10 Nonsterile Compounding Safety Note Regardless of their apparent stability, all suspensions should be dispensed with an auxiliary label reading “Shake Well.” © Paradigm Publishing, Inc. 11 Nonsterile Compounding • Ointments – water-in-oil emulsions – Occlusive – Greasy – Not water washable • Creams – oil-in-water emulsions – Nonocclusive – Nongreasy – Water washable © Paradigm Publishing, Inc. 12 Nonsterile Compounding • Powder is a finely divided admixture of drugs and/or chemicals. • Powders range in size from very coarse (No. 8) to very fine (No. 80). • Dispensing of medicines in powder from is very rare. © Paradigm Publishing, Inc. 13 Nonsterile Compounding • Suppository – solid dosage form for insertion into body orifice – Rectum – Vagina – Urethra • Consists of active ingredient(s) in a base such as – Cocoa butter – Hydrogenated vegetable oil – Glycerinated gelatin © Paradigm Publishing, Inc. 14 Nonsterile Compounding Suppositories are prepared by – Melting base material – Adding active ingredient(s) – Pouring into a mold – Chilling to solidify the suppository © Paradigm Publishing, Inc. 15 Nonsterile Compounding • Capsules – solid dosage form with medicinal preparation inside a gelatin shell • Medicinal preparation may be – Powder – Granules – Liquid • Compounding for capsules may be necessary to provide an unusual dosage form. © Paradigm Publishing, Inc. 16 Nonsterile Compounding • Capsule shells consist of a body and cap and are made of – Gelatin – Sugar – Water • Available in standard sizes © Paradigm Publishing, Inc. 17 Nonsterile Compounding Commercially available synthetic hormones come in fixed doses for – Hormone replacement therapy (HRT) – Estrogen replacement therapy (ERT) © Paradigm Publishing, Inc. 18 Terms to Remember hormone replacement therapy (HRT) therapy consisting of some combination of estrogen, progestin (female), and androgen (male) hormones estrogen replacement therapy (ERT) treatment consisting of some combination of female hormones © Paradigm Publishing, Inc. 19 Nonsterile Compounding • Physician may want to individualize these hormones instead. • Bio-identical hormones can be compounded to meet individual needs. • Dosing can be based on clinical observations or lab analysis of serum or saliva. • Hormones can be compounded as a gel or cream formulation. © Paradigm Publishing, Inc. 20 Laws, Regulations, and Standards for Compounding • Compounding pharmacies must be licensed. • Federal and state laws and national standards guide safety practices. • Compounding pharmacies must follow good compounding practices (see Table 8.2). © Paradigm Publishing, Inc. 21 Terms to Remember good compounding practices (GCP) USP standards in many areas of practice to ensure high-quality compounded preparations anticipatory compounding preparing excess product (besides an individual compound prescription) in reasonable quantities; these preparations must be labeled with lot numbers © Paradigm Publishing, Inc. 22 USP Chapter 795 • US Pharmacopeia developed standards for nonsterile compounding (Chapter 795): – Enhances patient safety – Protects pharmacists from law suits • FDA elects to use and enforce USP standards. © Paradigm Publishing, Inc. 23 Terms to Remember manufactured products products prepared off-site by a manufacturer compounded preparation a patient-specific medication prepared on-site by the technician, under the direct supervision of the pharmacist, from individual ingredients © Paradigm Publishing, Inc. 24 USP Chapter 795 • Contains policies and procedures for – Quality control, including quality of source ingredients – Verification – Patient counseling • Quality control also includes – Training of personnel – Maintaining stability and consistency of finished product – Preventing errors – Documenting expiration dates © Paradigm Publishing, Inc. 25 USP Chapter 795 • Material Safety Data Sheet must be filed for all stored ingredients. • Contains information on – Hazards and flammability – Procedures for treating accidental ingestion or exposure © Paradigm Publishing, Inc. 26 USP Chapter 795 • Compounded products have beyonduse dating, which is initiated at the time of compounding, not at the time of dispensing. • Product stability must be documented. © Paradigm Publishing, Inc. 27 Terms to Remember beyond-use dating the documentation of the date after which a compounded preparation expires and should no longer be used stability the extent to which a compounded product retains the same physical and chemical properties and characteristics it possessed at the time of preparation © Paradigm Publishing, Inc. 28 USP Chapter 795 • Chapter 795 provides estimates for beyond-use dating: – Refrigerated aqueous solutions = 14 days – Solids and nonaqueous solutions = 6 months or less – All other formulations = 30 days • When manufactured or bulk materials are used, take the earlier of these: – 25% of the remaining expiration date – 6 months © Paradigm Publishing, Inc. 29 USP Chapter 795 • Technician should always have pharmacist check beyond-use dating. • Beyond-use dating for sterile preparations is stricter: – It may be as little as 24 to 72 hours. – Both stability and sterility must be documented. © Paradigm Publishing, Inc. 30 Accreditation of Compounding Pharmacies • Many compounding pharmacies seek national accreditation: – Protects patients – Protects businesses from legal challenges – Differentiates their practices from those of other pharmacies • Pharmacy Compounding Accrediting Board (PCAB) is responsible for accrediting pharmacies. © Paradigm Publishing, Inc. 31 Accreditation of Compounding Pharmacies • To be accredited, pharmacy must agree to follow all specified standards • Must follow continuous quality improvement (CQI) process, including – Periodic spot-checks of technicians’ work – Random selection of product to be analyzed at an outside lab © Paradigm Publishing, Inc. 32 The Master Control Record • The master control record is the recipe for making the compounded prescription. • It is prepared by the pharmacist or provided by a compounding service. © Paradigm Publishing, Inc. 33 Terms to Remember master control record a recipe for a compound preparation that lists the name, strength, dosage form, ingredients and their quantities, mixing instructions, and beyond-use dating © Paradigm Publishing, Inc. 34 The Compounding Log • Generated for each prescription • Pharmacist uses it to complete the initial calculations and document them • Copy of the log (called the prescription record) is filed and used for refills © Paradigm Publishing, Inc. 35 Terms to Remember compounding log a printout of the prescription for a specific patient, including the amounts or weights of all ingredients and instructions for compounding; used by the technician to prepare a compounded medication for a patient © Paradigm Publishing, Inc. 36 Terms to Remember prescription record a computer-generated version of the compounding log that documents the compounding recipe for a specific prescription and patient © Paradigm Publishing, Inc. 37 The Compounding Log Compounding log lists – – – – – – – – – All ingredients of the compounded preparation Manufacturer Wholesaler source Assigned lot number NDC number Expiration date for each ingredient Quantity made Date of compounding Initials of pharmacist and compounding technician © Paradigm Publishing, Inc. 38 Calculations in the Compounding Pharmacy • Technician in a compounding pharmacy should have – Knowledge of mathematical conversions – Aptitude for performing calculations • Pharmacist is legally responsible for all calculations made by technicians • Good practice to double-check pharmacist’s calculations and those in the master control record © Paradigm Publishing, Inc. 39 Equipment • • • • • • Weights and Balances Pharmaceutical Weights Forceps and Spatulas Compounding Slab Mortar and Pestle Graduate Cylinders, Pipettes, and Beakers • Other Equipment © Paradigm Publishing, Inc. 40 Weights and Balances Technician must become familiar with weights and balances Class III prescription balance • Two-pan balance • Used to weigh small amounts (120 g or less) • Sensitivity requirement around +/– 6 mg • Uses pharmaceutical weights to offset ingredient weight © Paradigm Publishing, Inc. 41 Weights and Balances • Counterbalance – Two-pan balance – Used for larger weights (up to 5 kg) – Sensitivity requirement in the range of +/- 100 mg – Used for bulk materials, not for compounding • Ingredients and weights should be placed on weighing paper © Paradigm Publishing, Inc. 42 Terms to Remember weighing paper a special paper that is placed on a weighing balance pan to avoid contact between pharmaceutical ingredients and the balance tray; also called powder paper © Paradigm Publishing, Inc. 43 Weights and Balances Digital electronic balance – Single pan – Easier to operate than two-pan balance – More accurate – Much more expensive than two-pan balances ($2,500 or more) © Paradigm Publishing, Inc. 44 Terms to Remember digital electronic analytical balance a single-pan balance that is more accurate than Class III balances or counterbalances; has capacity of 100 g and sensitivity as low as +/–1 mg © Paradigm Publishing, Inc. 45 Pharmaceutical Weights • Used with two-pan balances to offset ingredient weight • Made of polished brass with noncorrosive coating • Set usually contains both metric and apothecary weights © Paradigm Publishing, Inc. 46 Forceps and Spatulas • Forceps are used for grasping small objects. • Forceps are used with pharmaceutical weights to avoid transferring moisture or oil from hands, which can change weight and cause measurement errors. © Paradigm Publishing, Inc. 47 Forceps and Spatulas • Spatulas are used for various tasks: – Transferring solid ingredients to weighing pans – Preparing ointments and creams – Removing material from mortar and pestle • Spatulas can be made of – Stainless steel – Plastic – Hard rubber (useful for corrosive materials) © Paradigm Publishing, Inc. 48 Terms to Remember forceps an instrument used to pick up small objects, such as pharmacy weights spatula a stainless steel, plastic, or hard rubber instrument used for transferring or mixing solid pharmaceutical ingredients © Paradigm Publishing, Inc. 49 Compounding Slab • Plate is made of ground glass: – Flat, hard, nonabsorbent surface – Used for mixing compounds • Disposable, nonabsorbent parchment paper can be used instead. © Paradigm Publishing, Inc. 50 Mortar and Pestle • Used for grinding and mixing ingredients • Can be made of glass, porcelain, or Wedgwood – Coarse-grained porcelain or Wedgwood best for pulverizing materials – Smooth glass sets best for mixing liquids and semisolids © Paradigm Publishing, Inc. 51 Graduate Cylinders, Pipettes, and Beakers • A Graduate cylinder is a flask used for measuring liquids: – Can be glass or polypropylene – Can be conical (wide top, narrow base) or cylindrical • Conical graduates are calibrated in both metric and apothecary units. • Cylindrical graduates are calibrated in metric units and are more accurate. © Paradigm Publishing, Inc. 52 Graduate Cylinders, Pipettes, and Beakers © Paradigm Publishing, Inc. 53 Graduate Cylinders, Pipettes, and Beakers Beakers are used to measure larger volumes of liquids: – Not as accurate as graduate cylinders – Used when precision is not required © Paradigm Publishing, Inc. 54 Graduate Cylinders, Pipettes, and Beakers A pipette is a long, thin, hollow tube: – Calibrated – Used to measure and transfer liquid volumes less than 1.5 mL – Sometimes suction device used to draw up liquid © Paradigm Publishing, Inc. 55 Other Equipment • Freezers and refrigerators – for storing ingredients and final products • Container hood, masks, and gowns – for protection when working with powders • Tablet press – for combining tablet ingredients • Capsule machine – for making larger quantities of capsules © Paradigm Publishing, Inc. 56 Other Equipment Sterile preparations require additional equipment and space: – Autoclave to sterilize instruments – Incubator to culture products – Clean room environment © Paradigm Publishing, Inc. 57 Attire and Preparation Requirements • Minimum requirements for nonsterile compounding – Hairnet – Long lab coat – Gloves • And for hazardous chemicals – – – – Eye goggles Mask Double gowning Eyewash station © Paradigm Publishing, Inc. 58 Attire and Preparation Requirements USP Chapter 795 also specifies the following: – All personnel must wash hands before and after each compounding procedure. – Disposable gloves must be discarded after each procedure. – No food items should be stored or consumed in the staging area. © Paradigm Publishing, Inc. 59 Technique for Weighing Pharmaceutical Ingredients • Accurately weighing ingredients is one of the most important parts of compounding. • The electronic balance is the preferred piece of equipment. © Paradigm Publishing, Inc. 60 Technique for Weighing Pharmaceutical Ingredients • Must be perfectly level (front to back and side to side) • Should be warmed up and calibrated each day prior to use • Should be locked when not in use • Must be cleaned after each use © Paradigm Publishing, Inc. 61 Technique for Weighing Pharmaceutical Ingredients • Class III prescription balance is sufficient for occasional compounding. • Pharmacist must check all measurements done by technician. © Paradigm Publishing, Inc. 62 Calculating Percentage of Error • Error in measurement is expected in nonsterile compounding. • Allowances are made for a certain percentage of error. • Most balances are marked with their degree of accuracy. • Percentage of error is calculated as (amount of error / quantity desired) x 100 © Paradigm Publishing, Inc. 63 Terms to Remember percentage of error the acceptable range of variation above and below the target measurement; used in compounding and manufacturing © Paradigm Publishing, Inc. 64 Technique for Measuring Liquid Volumes • Always select the measuring device that yields the most accurate volume. • Use the smallest device that holds the required volume. • Measure the liquid at eye level. • Read the level at the bottom of the meniscus. © Paradigm Publishing, Inc. 65 Terms to Remember meniscus the moon-shaped or concave appearance of a liquid in a graduate cylinder used in measurement © Paradigm Publishing, Inc. 66 Technique for Measuring Liquid Volumes Safety Note Always measure liquids on a solid, level surface at eye level. © Paradigm Publishing, Inc. 67 Techniques for Mixing Compounded Drugs • Technician should first gather these items: – – – – Master control record Ingredients Equipment Mixing directions • Adequate and uninterrupted time must be provided. • Best mixing technique should be retrieved from the master control record or from the pharmacist. © Paradigm Publishing, Inc. 68 Techniques for Mixing Compounded Drugs • Comminution is the act of reducing a substance to small, fine particles. • Blending is the act of combining two substances. • Trituration involves rubbing or grinding a substance to create fine particles: – Generally done with mortar and pestle – Rapid motion with minimal pressure produces best results © Paradigm Publishing, Inc. 69 Terms to Remember comminution the act of reducing a substance to small, fine particles, including trituration, levigation, pulverization, spatulation, sifting, and tumbling blending the act of combining two substances © Paradigm Publishing, Inc. 70 Techniques for Mixing Compounded Drugs • Levigation is used when reducing particle size for use in ointments. • A paste is formed with the solid and a levigating agent: – Castor oil – Mineral oil • The paste is then triturated with a mortar and pestle. © Paradigm Publishing, Inc. 71 Terms to Remember levigation a process usually used to reduce the particle size of a solid during the preparation of an ointment © Paradigm Publishing, Inc. 72 Techniques for Mixing Compounded Drugs • Pulverization by intervention reduces particle size with the use of a volatile solvent: – Camphor – Alcohol – Iodine – Ether • The solvent is then permitted to evaporate. © Paradigm Publishing, Inc. 73 Techniques for Mixing Compounded Drugs • Spatulation uses a spatula to combine and mix • Sifting is used to blend powders • Tumbling involves placing powders into a container and shaking © Paradigm Publishing, Inc. 74 Techniques for Mixing Compounded Drugs • Most ointments and creams are prepared with manual incorporation of materials. • In some cases, dry ingredients must be triturated to avoid a gritty appearance. © Paradigm Publishing, Inc. 75 Techniques for Mixing Compounded Drugs • Powders can be combined using one of the following techniques: – Spatulation – Trituration – Sifting – Tumbling – Levigation • A diluent powder may be necessary for pediatric doses. © Paradigm Publishing, Inc. 76 Terms to Remember diluent powder mixing an inactive ingredient that is added to the active drug in compounding a tablet or capsule © Paradigm Publishing, Inc. 77 Techniques for Compounded Drugs • Hand-filling capsules can be done with the punch method. • The body of the capsule is punched into a cake of powder until it is full. © Paradigm Publishing, Inc. 78 Techniques for Mixing Compounded Drugs • Mortar and pestle can be used to mix more than one drug. • Geometric dilution method begins by adding the most potent drug. • An equal amount of the next most potent drug is added and mixed. • Each successive addition should equal the amount in the mortar. © Paradigm Publishing, Inc. 79 Terms to Remember geometric dilution method the gradual combining of drugs using a mortar and pestle © Paradigm Publishing, Inc. 80 The Compounding Process • USP Chapter 795 lists fourteen steps for compounding a nonsterile preparation. • These steps, or something similar, should be included in the pharmacy’s procedure manual. © Paradigm Publishing, Inc. 81 The Compounding Process Safety Note Compounding should never be rushed. © Paradigm Publishing, Inc. 82 The Compounding Process 1. The pharmacist judges the suitability of the prescription to be compounded in terms of safety and intended use. 2. The pharmacist retrieves and reviews the master control record in the computer. (See Table 8.6) © Paradigm Publishing, Inc. 83 The Compounding Process 3. The pharmacist prints out a compounding record or log sheet for the technician to make the nonsterile preparation. 4. A medication container label is typed or created by the computer software using information in the compounding log. (See Table 8.6) © Paradigm Publishing, Inc. 84 The Compounding Process 5. The pharmacist performs all necessary mathematical calculations and identifies the necessary equipment for the technician; the technician double-checks all calculations. 6. The pharmacy technician uses appropriate protective clothing and handwashing technique. (See Table 8.6) © Paradigm Publishing, Inc. 85 The Compounding Process 7. The technician gathers all necessary active and inactive ingredients, as well as prepares and calibrates any necessary equipment. 8. The technician weighs and adds all ingredients for the preparation, initials each step, and adds documentation to the compounding record. (See Table 8.6) © Paradigm Publishing, Inc. 86 The Compounding Process 9. The technician labels and stores the medication in a suitable container. 10. The pharmacist reviews the compounding record and medication container label and assesses the pharmaceutical elegance of the preparation (See Table 8.6) © Paradigm Publishing, Inc. 87 The Compounding Process 11. The technician prepares a medication container label, affixing it to the proper container. 12. The pharmacist signs and dates the compounding record and/or prescription, files the records, and places the compounded preparation in a storage bin for patient pickup. (See Table 8.6) © Paradigm Publishing, Inc. 88 The Compounding Process 13. The technician cleans all equipment thoroughly and promptly, reshelves all active and inactive ingredients, and properly labels and stores any excess preparation. 14. The pharmacist counsels the patient at the time of pickup. (See Table 8.6) © Paradigm Publishing, Inc. 89 The Compounding Process • • • • • Selecting medication containers Labeling and cleanup Final check by the pharmacist Patient counseling by the pharmacist Reimbursement © Paradigm Publishing, Inc. 90 Selecting Medication Containers • Technician should choose the best container for the specific drug dispensed. – Amber-colored vials protect product from light. – Oral syringes are calibrated for dispensing creams and gels. – New TopiClick container dispenses a measured amount of medication. © Paradigm Publishing, Inc. 91 Labeling and Cleanup After compounding – Prescription must be labeled with all required information. – Prescription balance should be locked and covered. – Equipment and work area should be thoroughly cleaned. – Ingredients should be properly stored. – Expired or discarded product should be sealed and placed in a biohazard container. © Paradigm Publishing, Inc. 92 Final Check by the Pharmacist Pharmacist is legally responsible for checking the final product: – Master control record – Mathematical calculations – Weight measurements – Container label © Paradigm Publishing, Inc. 93 Final Check by the Pharmacist Pharmacist also checks the pharmaceutical elegance of the product: – Adequacy of mixing – Odor – Color – Consistency – pH balance © Paradigm Publishing, Inc. 94 Terms to Remember pharmaceutical elegance the physical appearance of the final compound preparation © Paradigm Publishing, Inc. 95 Patient Counseling by the Pharmacist • Pharmacist must offer counseling to all patients regarding compounded preparations. • Pharmacist should ensure that the patient knows – How to take the medication – How to properly store the medication – The beyond-use or expiration date of the medication © Paradigm Publishing, Inc. 96 Reimbursement • Insurance generally does not cover compounded preparations. • The cost to the patient is based on time and experience of staff, not on the cost of the ingredients. • Some insurance companies will accept a Universal Claim Form from the pharmacy and reimburse the patient later. © Paradigm Publishing, Inc. 97