LukaQuality Assurance Manual (Eng)

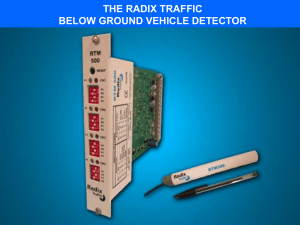

advertisement