Industrial Variable Reluctance Sensor

ME8843

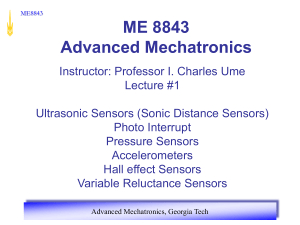

ME 8843

Advanced Mechatronics

Instructor: Professor I. Charles Ume

Lecture #1

Ultrasonic Sensors (Sonic Distance Sensors)

Photo Interrupt

Pressure Sensors

Accelerometers

Hall effect Sensors

Variable Reluctance Sensors

Advanced Mechatronics, Georgia Tech

ME8843

• Ultrasonic transducer (piezoelectric transducer) is device that converts electrical energy into ultrasound

• Upon receiving sound echo (pressure wave) back from surface, ultrasound transducer will turn sound waves into electrical energy which can be measured and displayed

• Ultrasound are sound waves above normal range of human hearing (greater than 20K hertz).

Advanced Mechatronics, Georgia Tech

ME8843

Since piezoelectric crystal generates voltage when force is applied to it, same crystal can be used as an ultrasonic detector

Some systems use separate transmitter and receiver components while others combine both in single piezoelectric transceiver

Alternative methods for creating and detecting ultrasound include magnetostriction and capacitive actuation .

Pulse echo sensor

Transmit-Receive sensor

Advanced Mechatronics, Georgia Tech

ME8843

• Sound is transmitted through propagation of pressure in air

• Speed of sound in air is normally 331 m/sec at

0 o C and 343 m/sec at 20 o C for dry air

• Digital signal processor embedded in sensor calculates distance between sensor and object

Advanced Mechatronics, Georgia Tech

ME8843

x = v sound

. t

Where V sound is known, t = 0.5 (time of flight), x is distance between sensor head and object

Range of sensor varies between 5 cm to 20 m

Sensor is not appropriate for very short distance measurements

Frequency response (distance measurement update rate) varies with distance measured

– In general, it is about 100 Hz

Advanced Mechatronics, Georgia Tech

ME8843

• Piezoelectric crystals have property of changing size when voltage is applied

• Applying alternating current ( AC ) across them causes them to oscillate at very high frequencies, thus producing very high frequency sound waves.

• Ultrasonic sensors work on principle similar to radar or sonar

–Evaluate attributes of target by interpreting echoes from radio or sound waves respectively

Advanced Mechatronics, Georgia Tech

ME8843

Ultrasonic sensors generate high frequency sound waves and evaluate echo which is received back by the sensor

Sensors calculate time interval between sending signal and receiving echo to determine distance to object.

Advanced Mechatronics, Georgia Tech

ME8843

Applications

Medical:

Medical ultrasonic transducers (probes) come in variety of different shapes and sizes for use in making pictures of different parts of body.

Transducer may be passed over surface of body or inserted into body opening such as rectum or woman’s reproductive organ

Clinicians who perform ultrasound-guided procedures often use a probe positioning system to hold the ultrasonic transducer.

Advanced Mechatronics, Georgia Tech

ME8843

Technology can be used for measuring:

– Often used in robots for obstacle avoidance

– Wind speed and direction (anemometer),

– Fullness of tank, and speed through air or water

– Measuring amount of liquid in tank, sensor measures distance to surface of fluid.

– Other applications include: burglar alarms, non-destructive testing, and etc

Advanced Mechatronics, Georgia Tech

ME8843

Photo Interrupt

• Uses emitter and detector photo diode pair

• With no obstruction detector is high

• When an object blocks the light the detector is low

• Advantages

– Simple to interface

– Inexpensive

– Reliable

Advanced Mechatronics, Georgia Tech

ME8843

Photo Interrupt

Types

• Wide variety of packages and orientations

• Types

– Logic (digital ± 5 volts)

– Transistor/diode (analog)

• Manufacturers

– Fairchild

– Honeywell

Advanced Mechatronics, Georgia Tech

ME8843

Photo Interrupt

Applications

• Encoder wheel for angular measurements.

– Computer mouse with a ball

Advanced Mechatronics, Georgia Tech

ME8843

Photo Interrupt

Applications

• Detect holes or slots for positioning of liner slides

– Elevators

• Detect the location of products

– Assembly line

Advanced Mechatronics, Georgia Tech

ME8843

Pressure Sensors

• Used to detect pressure of fluids or gasses .

• Technologies (many)

– Strain gage

– Piezoresistive

– Microelectromechanical systems (MEMS)

• Each sensor has a pressure range that it works in.

• Most have analog outputs that need amplification

– Some have built-in amplifiers for direct connection into microcontroller

Advanced Mechatronics, Georgia Tech

ME8843

Pressure Sensors

Types

• Differential Pressure

– Difference between two or more pressures introduced as inputs to the sensing unit

– 2 input

• Absolute/Gage Pressure

– Pressure relative to perfect vacuum pressure or set pressure

(such as pressure at sea level)

– 1 input

Advanced Mechatronics, Georgia Tech

ME8843

Pressure Sensors

Applications

• Measure pressure of gas or fluids

• Measure altitude

– For planes or weather balloons

• Measure flow

– pressure sensors in conjunction with the venturi effect to measure flow

• Measure depth of water

– When measuring liquids, most sensors are not rated to have unclean liquids contact the sensor components. A small amount of air in the tube right before the sensor will create a barrier from the liquid.

Advanced Mechatronics, Georgia Tech

ME8843

Accelerometers

• Used to measure acceleration

– Common SI units meters/second2 (m/s2) or popularly in terms of g-force (1 g is earth’s gravity)

• At rest an acceleration will measure 1 g in the vertical direction

• They can come in 1, 2 or 3 axis configurations

– With 3 axis it gives a vector of the accelerations direction (after

ME8843

Accelerometers

• Because of earth’s gravity, the sensor will read 1 to 0 g as the sensor is rotated from being vertical to horizontal.

– This can be used to measure angle the of tilt

• Each sensor has a range that it works in.

• Most have analog outputs that need amplification

– Some have built-in amplifiers for direct connection into microcontroller

Advanced Mechatronics, Georgia Tech

ME8843

Accelerometers

How they work

• Mechanically the accelerometer behaves as a mass-damper-spring system

– Many use Microelectromechanical systems (MEMS). Which use very small cantilever beams with masses on them

• Under the influence of gravity or acceleration, the proof mass deflects from its neutral position.

• This deflection is measured in an analog or digital manner

– Commonly the capacitance between a set of fixed beams and a set of beams attached to the proof mass is measured.

– Integrating piezoresistors in the springs to detect spring deformation is another method

Advanced Mechatronics, Georgia Tech

ME8843

Accelerometers

Applications

• Can be used to sense orientation, vibration and shocks.

• Used in electronics like the Wii and iPhone for user input.

• Acceleration integrated once gives velocity, integrated a second time gives position.

– The integration process is not precise and introduces error into the velocity and position.

Advanced Mechatronics, Georgia Tech

ME8843

Hall Effect Sensors

• Used to provide a noncontact means to detect and measure a magnetic field

• Named based on their use of the

Hall Effect , discovered by

Edwin Hall in 1879

Hall Effect Sensor Sensing a Shaft Speed http://farm1.static.flickr.com/62/227729006_fab88c1668.jpg?v=

0

Advanced Mechatronics, Georgia Tech

ME8843

How they work

• Presence of magnetic field deflects electrons flowing through a conductive material

Depiction of the Hall Effect

• As electrons move to one end of a conductive material, a potential is developed in the direction perpendicular to gross current flow

• This potential indicates the strength of the magnetic field http://upload.wikimedia.org/wikipedia/commons/a/ab/Ha ll_effect_A.png

Advanced Mechatronics, Georgia Tech

ME8843

Applications

• IC Engine Electronic Ignition Systems

– Used to determine position of cam shaft

• Brushless DC Motor Control

– Sensors determine position of permanent magnet rotor

• Assembly Lines

– Shaft position and velocity sensors

– Contactless limit switches

• Current Sensing ICs

– Electrically isolated alternative to shunt resistors

Advanced Mechatronics, Georgia Tech

ME8843

Hall Effect Sensor Types

• Linear Hall Effect Sensors

– Output is proportional to magnetic field strength

• Hall Effect Digital Switches

– Presence of field above threshold turns switch on

– Presence of field below threshold turns switch off

• Hall Effect Digital Latches

– North field turns latch on

ME8843

Packaging and Manufacturers

• ICs

– Analog Devices:

• AD22151G from Analog Devices

– Allegro MicroSystems, Inc.

• Wide range of linear, latching and switching sensors

• Great sampling policy

– Many, many more

SOT23

SIP http://www.allegromicro.com/en/Products/P art_Numbers/1120/pinout.gif

• Packaged units

– Honeywell

– Many, many more

Hall Effect

Sensor Module http://sensing.honeywell.com/client_asset/do cument/1/5/4/0/3/5/document_C3697B35-

Advanced Mechatronics, Georgia Tech C930-CB7C-FE090DFFCE61FB22.jpg

ME8843

Implementation and Words of

Warning

• Sensors may be affected by temperature variation . Some sensors incorporate circuitry to reduce this error.

• Sensors may be directional , in which case care must be taken with respect to orientations of sensor and magnet

• Some Hall Effect sensors detect presence of ferromagnetic materials, not magnetic fields

Advanced Mechatronics, Georgia Tech

ME8843

Variable Reluctance Sensors

• Used to measure speed and/or position of a moving metallic object

• Sense the change of magnetic reluctance/resistance (analogous to electrical resistance) near the sensing element

• Require conditioning circuitry to yield a useful signal (e.g. LM1815 from National Semi.)

Industrial Variable

Reluctance Sensor http://www.motionsensors.com/railwithoring

2.jpg

Advanced Mechatronics, Georgia Tech

ME8843

How Variable Reluctance Sensors

Work

• A magnet in the sensor creates a magnetic field

• As a ferrous object moves by the sensor , the resulting change in the magnetic flux induces an emf in the pickup coil

Variable Reluctance Sensor

Construction

Typical Configuration http://www.instronics.com/images/sensoronix/image.ds.drawing.v

Advanced Mechatronics, Georgia Tech r.jpg

ME8843

Typical Application

• Shaft velocity sensor for ABS/traction control

• Crank and cam shaft position sensors

Installed on CV axle

Sensor Schematic http://www.me.gatech.edu/mechatronics_lab/Projects/Spring07/Group1/dorthy

6.JPG

Advanced Mechatronics, Georgia Tech

ME8843

Interfacing Concerns

Emf is proportional to the rate of change of the magnetic flux.

Indictates the ferrous material must be moving for the sensor to generate a signal.

Output voltage depends on velocity of toothed wheel

Performance may be reduced at slow speeds

Advanced Mechatronics, Georgia Tech