1. Strengthening and recrystallization of plastically deformed metals

advertisement

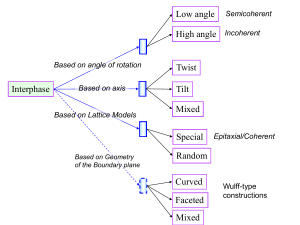

Lecture 6 1. Strengthening and recrystallization of plastically deformed metals. 2. Material selection according to the mechanical properties Why study strengthening mechanisms? We can tailor the mechanical properties of an engineering material by choosing between strength and toughness Plastic Deformation Plastic deformation is permanent, and strength and hardness are measures of a material’s resistance to this deformation. On a microscopic scale, plastic deformation corresponds to the net movement of large numbers of atoms in response to an applied stress. In crystalline solids, plastic deformation most often involves the motion of dislocations The ability of a metal to plastically deform depends on the ability of dislocations to move Dislocation Motion Cubic 4 & hexagonal metals - plastic deformation by plastic shear or slip where one plane of atoms slides over adjacent plane by defect motion (dislocations). • If dislocations don't move, deformation doesn't occur! Dislocation Motion 5 The process by which plastic deformation is produced by dislocation motion is termed slip Dislocation moves along slip plane in slip direction perpendicular to dislocation line Edge dislocation Screw dislocation Strengthening of Metals Good industrial alloys -> high strengths yet some ductility and toughness Since hardness and strength are related to the ease with which plastic deformation can be made to occur, by reducing the mobility of dislocations, the mechanical strength may be enhanced In contrast, the more unconstrained the dislocation motion, the greater is the facility with which a metal may deform, and the softer and weaker it becomes Restricting or hindering dislocation motion renders a material harder and stronger Strengthening Methods grain size reduction, solid-solution alloying, precipitation hardening/strengthening strain hardening/strengthening 8 Strategies for Strengthening: 1: Reduce Grain Size • Grain boundaries are barriers to slip. • Barrier "strength" increases with Increasing angle of misorientation. • Smaller grain size: more barriers to slip. • Hall-Petch Equation: yield o k y d 1 / 2 d is the average grain diameter. σo and ky are constants for a particular material Dependence of Yield Strength on Grain Size The influence of grain size on the yield strength of a 70 Cu–30 Zn brass alloy 10 Strategies for Strengthening: 2: Solid Solution Strengthening • Impurity atoms distort the lattice & generate stress. • Stress can produce a barrier to dislocation motion. • Smaller substitutional impurity • Larger substitutional impurity A C B D 11 Stress Concentration at Dislocations SSS - Impurity Atoms SSS – Effects of Impurity Atoms The resistance to slip is greater when impurity atoms are present because the overall lattice strain must increase if a dislocation is moved away from them. The same lattice strain interactions will exist between impurity atoms and dislocations that are in motion during plastic deformation. Thus, a greater applied stress is necessary to first initiate and then continue plastic deformation for solid-solution alloys, as opposed to pure metals SSS – Strength and Ductility Variation with nickel content of (a) tensile strength, (b) yield strength, and (c) ductility (%EL) for copper–nickel alloys, showing strengthening. Strategies for Strengthening: 3: Precipitation Strengthening Precipitation strengthening, also called age hardening, is a heat treatment technique used to increase the yield strength of malleable materials. It relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal's lattice. Precipitation in solids can produce many different sizes of particles, which have different properties. Alloys must be kept at elevated temperature for hours to allow precipitation to take place. This time delay is called aging 16 Strategies for Strengthening: 3: Precipitation Strengthening • Hard precipitates are difficult to shear. Ex: Ceramics in metals (SiC in Iron or Aluminum). precipitate Large shear stress needed to move dislocation toward precipitate and shear it. Side View Top View Unslipped part of slip plane S Slipped part of slip plane • Result: y~ 1 S Dislocation “advances” but precipitates act as “pinning” sites with spacing S. 17 Application: Precipitation Strengthening • Internal wing structure on Boeing 767 • Aluminum is strengthened with precipitates formed by alloying. 1.5mm 18 Strategies for Strengthening: 4: Strain-Hardening • Room temperature deformation. • Common forming operations change the cross sectional area: -Forging force die A o blank -Rolling roll Ao Ad Ad roll -Drawing die Ao force Ad -Extrusion Ao tensile force force die container ram billet container Ao Ad % CW x 100 Ao die holder extrusion die Ad 19 Dislocations During Cold Work • Ti alloy after cold working: • Dislocations entangle with one another during cold work. • Dislocation motion becomes more difficult. 0.9 mm Result of Cold Work 20 total dislocation length Dislocation density = unit volume Carefully grown single crystal 103 mm-2 Deforming sample increases density 109-1010 mm-2 Heat treatment reduces density 105-106 mm-2 • Yield stress increases as dislocation density increases: y1 y0 large hardening small hardening e Impact of Cold Work 21 As cold work is increased • Yield strength (y) increases. • Tensile strength (TS) increases. • Ductility (%EL or %AR) decreases. 22 Cold Work Analysis • What is the tensile strength & ductility after cold working? 2 Copper Cold Work 2 ro rd % CW x 100 35 . 6 % 2 ro yield strength (MPa) tensile strength (MPa) 700 800 500 600 300 300MPa 100 0 20 Cu 40 % Cold Work y = 300MPa 60 Do =15.2mm Dd =12.2mm ductility (%EL) 60 40 Cu 20 400 340MPa 200 0 Cu 7% 20 40 60 % Cold Work TS = 340MPa 00 20 40 60 % Cold Work %EL = 7% -e Behavior vs. Temperature 23 800 Stress (MPa) • Results for polycrystalline iron: -200C 600 -100C 400 25C 200 0 0 0.1 0.2 0.3 0.4 Strain • y and TS decrease with increasing test temperature. • %EL increases with increasing test temperature. 3. disl. glides past obstacle • Why? Vacancies 2. vacancies help dislocations replace move past obstacles. atoms on the obstacle disl. half plane 1. disl. trapped by obstacle 0.5 24 Effect of Heating After %CW • 1 hour treatment at Tanneal... decreases TS and increases %EL. • Effects of cold work are reversed! 100 200 300 400 500 600 700 600 60 tensile strength 50 500 40 400 30 ductility 300 20 ductility (%EL) tensile strength (MPa) annealing temperature (ºC) • 3 Annealing stages to discuss... 25 Recovery Annihilation reduces dislocation density. • Scenario 1 Results from diffusion • Scenario 2 extra half-plane of atoms atoms diffuse to regions of tension extra half-plane of atoms 3. “Climbed” disl. can now move on new slip plane 2. grey atoms leave by vacancy diffusion allowing disl. to “climb” 1. dislocation blocked; can’t move to the right Dislocations annihilate and form a perfect atomic plane. tR 4. opposite dislocations meet and annihilate Obstacle dislocation Recrystallization Even after recovery is complete, the grains are still in a relatively high strain energy state Recrystallization is the formation of a new set of strain-free and equiaxed grains (i.e., having approximately equal dimensions in all directions) that have low dislocation densities and are characteristic of the precold-worked condition. The new grains form as very small nuclei and grow until they completely consume the parent material, processes that involve short-range diffusion Recrystallization 27 • New grains are formed that: -- have a small dislocation density -- are small -- consume cold-worked grains. 0.6 mm 33% cold worked brass 0.6 mm New crystals nucleate after 3 sec. at 580C. Further Recrystallization 28 • All cold-worked grains are consumed. 0.6 mm After 4 seconds 0.6 mm After 8 seconds Recrystallization During recrystallization, the mechanical properties that were changed as a result of cold working are restored to their precold-worked values; that is, the metal becomes softer, weaker, yet more ductile Recrystallization is a process the extent of which depends on both time and temperature. The degree (or fraction) of recrystallization increases with time For pure metals, the recrystallization temperature is normally 0.3Tm where Tm is the absolute melting temperature Grain Growth After recrystallization is complete, the strain-free grains will continue to grow if the metal specimen is left at the elevated temperature; this phenomenon is called grain growth Grain growth does not need to be preceded by recovery and recrystallization; it may occur in all polycrystalline materials, metals and ceramics alike Grain Growth 31 • At longer times, larger grains consume smaller ones. • Why? Grain boundary area (and therefore energy) is reduced. 0.6 mm After 8 s, 580ºC 0.6 mm After 15 min, 580ºC • Empirical Relation: exponent typical. ~ 2 grain diam. n n d d Kt at time t. o After 10 min, 700ºC coefficient dependent on material and T. elapsed time Ostwald Ripening º 32 TR = recrystallization temperature TR º Time and Temperature Dependent Grain Growth Recrystallization Temperature, TR 34 TR = recrystallization temperature = point of highest rate of property change 1. Tm => TR 0.3-0.6 Tm (K) 2. Due to diffusion annealing time TR = f(t) shorter annealing time => higher TR 3. Pure metals lower TR due to dislocation movements Easier to move in pure metals => lower TR 35 Coldwork Calculations A cylindrical rod of brass originally 0.40in (10.2mm) in diameter is to be cold worked by drawing. The circular cross section will be maintained during deformation. A coldworked tensile strength in excess of 55,000psi (380MPa) and a ductility of at least 15%EL are desired. Furthermore, the final diameter must be 0.30in (7.6mm). Explain how this may be accomplished. 36 Coldwork Calculations Solution If we directly draw to the final diameter what happens? Brass Cold Work Do = 0.40 in Ao Af % CW Ao Df = 0.30 in Af x 100 1 x 100 A o 2 Df 4 1 1 x 100 2 D 4 o 2 0 . 30 x 100 43 . 8 % 0 . 40 37 Coldwork Calc Solution: Cont. 420 540 6 For %CW = 43.8% – y = 420 MPa – TS = 540 MPa > 380 MPa – %EL = 6 < 15 • This doesn’t satisfy criteria…… what can we do? 38 Coldwork Calc Solution: Cont. 15 380 27 12 For TS > 380 MPa > 12 %CW For %EL < 15 < 27 %CW our working range is limited to %CW = 12-27 39 Coldwork Calc Soln: Recrystallization Cold draw-anneal-cold draw again For objective we need a cold work of %CW 12 - 27 We’ll use %CW = 20 Diameter after first cold draw (before 2nd cold draw)? must be calculated as follows: 2 Df 2 % CW 1 2 D 02 Df 2 D 02 % CW 1 100 Intermediate diameter = x 100 0 .5 D f 1 D 02 1 Df 2 D 02 D 02 2 2 % CW 100 Df 2 0 .5 % CW 1 100 0. 5 20 0 . 30 1 100 0 . 335 in 40 Coldwork Calculations Solution Summary: 1. Cold work D01= 0.40 in Df1 = 0.335 in 2 0 . 335 % CW 1 1 x 100 30 % 0 . 4 2. 3. Anneal to remove all CW effects; D02 = Df1 Cold work D02= 0.335 in Df 2 =0.30 in 2 0 . 3 % CW 2 1 x 100 20 % 0 . 335 Therefore, meets all requirements y 340 MPa TS 400 MPa % EL 24 Material Selection According to the Mechanical Properties Material Selection – The Basics Getting the optimum balance of performance, quality, and cost requires a careful combination of material and part design The ideal product is one that will just meet all requirements. Anything better will usually incur added cost through higher-grade materials, enhanced processing, or improved properties that may not be necessary. Anything worse will likely cause product failure, dissatisfied customers, and the possibility of unemployment Material Selection – The Basics The interdependence between materials and their processing must also be recognized. New processes frequently accompany new materials, and their implementation can often cut production costs and improve product quality. A change in material may well require a change in the manufacturing process Improper processing of a well-chosen material can definitely result in a defective product. Materials and Manufacturing • An engineering material may possess different properties depending upon its structure. • Processing of that material can alter the structure, which in turn will alter the properties. • Altered properties certainly alter performance. PROCEDURES FOR MATERIAL SELECTION Every engineered item goes through a sequence of activities that includes: design material selection process selection production evaluation possible redesign or modification Requirements for Material Selection (1) shape or geometry considerations, (2) property requirements, (3) manufacturing concerns 1. GEOMETRIC CONSIDERATIONS What is the relative size of the component? How complex is its shape? What are the surface-finish requirements? Must all surfaces be finished? Could a minor change in part geometry increase the ease of manufacture or improve the performance (fracture resistance, fatigue resistance, etc.) of the part? 2. Mechanical Properties How much static strength is required? If the part is accidentally overloaded, is it permissible to have a sudden brittle fracture, or is plastic deformation and distortion a desirable precursor to failure? How much can the material bend, stretch, twist, or compress under load and still function properly? Are any impact loadings anticipated? If so, of what type, magnitude, and velocity? 2. Mechanical Properties Can you envision vibrations or cyclic loadings? If so, of what type, magnitude, and frequency? Is wear resistance desired? Where? How much? How deep? Will all of the above requirements be needed over the entire range of operating temperature? If not, which properties are needed at the lowest extreme? At the highest extreme? Environmental Considerations What are the lowest, highest, and normal temperatures the product will see? Will temperature changes be cyclic? How fast will temperature changes occur? What is the most severe environment that is anticipated as far as corrosion or deterioration of material properties is concerned? What is the desired service lifetime for the product? 3. Manufacturing Concerns How many of the components are to be produced? At what rate? What is the desired level of quality compared to similar products on the market? Has the design addressed the requirements that will facilitate ease of manufacture? Ashby Material Selection Charts E MCH 213D