Topic 16 Strain Hardening, Hot Working and Annealing

advertisement

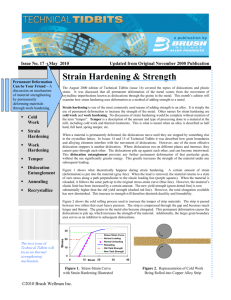

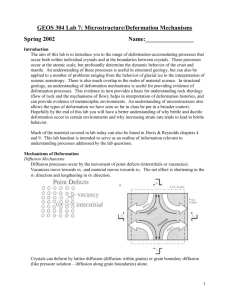

Chapter 8 Strain Hardening, Hot Working and Annealing Line Defects - Dislocations • Line Imperfections in the lattice of a crystalline material. • Movement of dislocations => material deformation • Interference with movement of dislocations => material strengthened • Types: – Edge – Screw – Mixed Edge Dislocation Screw Dislocation Blocking Slip = Material Strengthening • Slip: Deformation of a material by movement of dislocations through the Crystal Lattice • Movement of dislocations => material deformation • Interference with movement of dislocations => material strengthened Some Ways to Strengthen a Metal By Disrupting the Crystal Lattice • Alloy: – Solid Solution Strengthening – Dispersion Strengthening – Precipitation Hardening • Heat Treatment: – Controlled heating and cooling of metals for purpose of altering properties • Strain Harden or Cold Work Strain Hardening –Introduces Line Defects –Varied Strengths Grain Size Refining –Surface Defects –Varied Strengths Defects and Strengthening Mechanisms Solid Solution Strengthening –Single Phase –Point Defects –Low Strengthening Effect Exceed Solubility Limit Precipitation Hardening –Two Phase, Coherent –Point and Surface Defects + –High Strengthening Effect Dispersion Strengthening –Two Phase, Non-Coherent –Point and Surface Defect –Medium Strengthening Effect Strain Hardening • Plastic deformation below recrystallization temp • Simultaneously deforms and strengthens the metal Cold Working Simple Cold Rolling % Cold Work = ((Ao - Af)/Ao) x 100% Where: Ao = original x-sectional area Af = final x-sectional area Other Cold Working Techniques: •Forging •Rolling •Drawing •Extrusion •Stretch Forming •Misc Microstructural Mechanism Responsible for Strain Hardening in Metals • Increases number of dislocations (line imperfections) • Dislocations get in the way of other dislocations trying to move or slip • Provides higher strength, hardness but lower toughness. Frank - Read Source Advantages of Cold Working Metals – Provides excellent surface finish – Simultaneously strengthen metal and produce desired shape – Inexpensive for producing large number of small parts – Properly controlled residual stresses and anisotropic behavior may be beneficial – May be the only method available for accomplishing certain tasks – FCC metals respond well to coldworking – HCP metals do not respond well to coldworking Disadvantages of Cold Working Metals – Not practical for all types of metal – Ductility, corrosion resistance, electrical conductivity impaired by cold working Can we strain harden polymers? Deformation of Polymers Strain Hardening of Plastics • Polymer chains become aligned • Provides increase in tensile strength • Anisotropic properties Stages of Annealing – Team Work – Recovery • Rearranges dislocations, but does not eliminate them • So-----how might this affect the properties? – Recrystallization • Small grains nucleate at boundaries of dislocations, eliminate most of the dislocations • So---how might this affect the properties – Grain growth • grains grow larger • So---how might this affect the properties Annealing Three stages: – Recovery – Recrystallization – Grain growth Annealing • Heat treatment used to eliminate all or part of the effects of cold working • Three stages – Recovery • Reduces or eliminates residual stresses • Does not change mechanical properties • Restores electrical conductivity and improves corrosion resistance • Relatively low temp heat treat • Produces a polygonized subgrain structure – Recrystallization • Material heated above recrystallization temp. • Small grains nucleate at boundaries of polygonized structure • Eliminates most dislocations=> strength reduced and ductility restored – Grain growth • grains grow larger => lower strength and higher ductility • Too large of grains generally undesirable Recrystallization and Grain Growth Cold Worked Brass 3 s @ 580 C New grains start to appear 4 s @ 580 C Many new grains are present Annealing Complete Recrystallization Substantial grain growth Some Factors Affecting the Recrystallization Temperature Effect of Cold Work Effect of Melting Temperature Heat Affected Zone in a Weld Hot Working Hot Working • Plastically deforming a material above its recrystallization temperature • No strengthening occurs (simultaneously annealing the material!) • Essentially no limit on the amount of deformation • Suitable for a wider range of crystal structures since all materials become more ductile and weaker at elevated temperatures • Surface finish is not as great (like rolling warm cookie dough as opposed to hot cookie dough) • Surface may oxidize • Properties typically not anisotropic • Dimensional accuracy not as great since thermal expansion occurs Cold Working Processes • • • • • • • • • • • Cold Rolling Swaging Cold Forging Cold Extrusion Riveting Sizing Coining Hubbing Peening Burnishing Bending Hot Working Processes • • • • • • Rolling Forging Extrusion Hot Drawing Pipe Welding Piercing