Milk Collection in Western Norway Using Trucks and Trailers

ARILD HOFF

MOLDE UNIVERSITY COLLEGE

ARNE LØKKETANGEN

UROOJ PASHA

MILK COLLECTION IN

WESTERN NORWAY USING

TRUCKS AND TRAILERS

RESEARCH SEMINAR, MOLDE, JUNE 6th

A DAIRY COMPANY

TINE BA

• The leading dairy company in Norway, owned by 18000 milk producers

• Core business is producing dairy products from raw milk

• We look at a subproblem: Collecting milk from 990 milk producers in the northern part of Møre og Romsdal County in

Western Norway

• 3 different dairy plants in the same district

DAIRY PLANTS

THE DAIRIES

• Circle – Elnesvågen

– 77.2% of total delivery

– Produces Jarlsberg, and other cheeses

• Star – Høgseth

– 17.4% of total delivery

– Produces milk for consumption

• Square – Tresfjord

– 5.4% of total delivery

– Produces cheeses Ridder and Port Salut

THE VEHICLES

• Each dairy has associated a certain number of heterogeneous cars, with or without trailers.

• The tanks have several compartments to avoid mixing:

– Ecological milk from some producers.

– Contaminated milk (antibiotics) from farms with possible diseases.

– Whey to be returned to the farms for animal food (waste product when producing cheese).

MILK COLLECTION

PROBLEM

• Collect milk from producers and deliver at the plants

• Each plant has a certain daily demand

• Milk can be stored in cooler tanks at the producers for at most three days

• Small farms which are inaccessible for a truck carrying a trailer

• The plans generated are seasonal

– Fixed routes for the season (winter and summer)

– Some slack (spare capacity) is incorporated due to varying daily production

CURRENT COLLECTION

STRUCTURE

• Milk can be stored for up to three days in cooler tanks at farms

– Expensive to change

• Collection is according to prespecified frequencies:

– 7 3 – Every third day, 7 days a week

– 7 2 – Every second day, 7 days a week

• Needs a smaller cooler tank at the farm

– 6 2 – Every second day, not sundays

• Needs same size tank as 7 3

SOLUTION STRUCTURE

• A trailer can be used as a mobile depot

• The truck leaves the trailer at a parking place and visits the farms to collect milk

• When the truck returns to the parked trailer, the milk can be transferred to the trailer tank and the truck are ready to collect milk from other farms

SOLUTION STRUCTURE

PARKING PLACES

SUPPLIERS

A REAL-WORLD PROBLEM

• Vehicle Routing.

• Multi Depot (3 plants in this district, totally 49 in

Norway).

• Pickup and Delivery (pickup milk, deliver whey).

• Fleet Size and Mix.

• Truck and Trailers / Satellite Depots

• Two-Echelon VRP

• Periodic VRP (frequency every 1, 2 or 3 days).

• Time Windows (to a small degree at suppliers, but also for meeting ferry times etc.).

INITIAL SOLUTION

1. Compute the number of tours necessary with reference to the available vehicle fleet, the visiting frequency and the needed supplies for each depot.

2. Select seed orders for each tour and cluster around these.

3. Optimize each tour using a simple local search.

4. Insert parking places for the tours that are served with a truck and trailer.

HEURISTIC

• Neighborhood structure

– Move or swap orders between two tours

– Reduce the neighborhood by only considering tours containing other close orders

– Partial neighborhood examination

HEURISTIC

• Reoptimization of subtours after change

• Try to improve each tour by moving orders to other subtours

• Recalculation to find optimal parking places

HEURISTIC

• Tabu Search

– Variable Tabu Tenure

– Diversification strategy to avoid that the same moves are performed too often

– Dynamic penalty for load-infeasible solutions are added to the objective value

(

)

( r

( L r

Q )

r

i

R r

( L t ir

Q t

)

)

DIVERSIFICATION

• ξ(s) = ψ(s) + η τ(s)

• ψ(s) is the number of h-neighbors order s has inside its own tour,

• τ(s) is the number of times order s is selected from the current tour.

• The order s with lowest value ξ(s) is selected for an eventual move from the tour as long as it is not declared tabu.

• (h-neighborhood – the set s S which consist of the h suppliers closest to s. A tour with none of the h closest suppliers is not considered for a move.)

17

DIVERSIFICATION

• Our test results are not unambiguous about the value of η.

• We have chosen to use the value η = 0.75 for our subsequent tests, as this value gave a slightly better result than the other alternatives.

18

PENALTY FACTOR

(

)

(

r

( L r

Q )

r i

R r

( L t ir

Q t

)

)

• β(σ) is the penalty for solution σ which are added to the objective function

• (x) + = max{0, x}.

• r is all tours in the solution

• R r are all subtours in tour r.

• Q is the capacity of the complete vehicle

• Q t

• L r is the capacity of the truck, is the total load in tour r and

• L t ir is the truckload on subtour i in tour r.

• The penalty factor α is initially set to 1 and adjusted during the search by multiplying or dividing it with a value κ when the solution is respectively feasible or infeasible. Preliminary tests show that the value κ = 1.1 gives best results in our search.

19

OBJECTIVE FUNCTION

f (

)

(

)

(

)

(

)

γ(σ) : Driving distance

ε(σ) : Additional costs i.e. for using ferrys or toll roads

β(σ): Penalty for infeasible solutions

COMPUTATIONAL

RESULTS

• Want to find out the effect of

– Truck/hanger size

– Collection strategy

– Effect of parking places

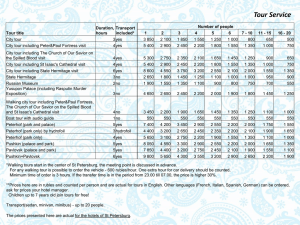

VEHICLE SIZES

Q v

Q t

Q x

M

ID

1

51

5

12

17

71

36

39

Q v

Q t

10000 10000

14500 14500

18500 18500

Q

0

0

0 x

21000 10000 11000

29000 10000 19000

33500 14500 19000

29500 18500 11000

33500 18500 15000

– Total vehicle capacity

– Capacity of the truck

– Capacity of the hanger

– Number of tours

Freq.

7x3

7x3

7x3

7x3

7x3

7x3

7x3

7x3

32

35

33

M Obj.value

95 6849.45

68

53

5312.21

4526.99

47

36

4856.26

4347.30

3875.62

3975.95

3480.90

COLLECTION STRATEGIES

2.50

2.00

1.50

1.00

0.50

1 51 5 12 17

Vehicle type

71 36 39

7x1

7x2

7x3

-

Clearly better to collect every third day

- Need bigger storage tanks at the farms

- In practice a mix of 7 2 and 7 3

ONE OR MORE PARKING

PLACES

ID Q v

Q t

Q x

71

71 p

33500 14500 19000

33500 14500 19000

39

39 p

33500 18500 15000

33500 18500 15000

Freq.

7x3

7x3

7x3

7x3

M Obj.value

32 3875.62

33

33

32

4292.43

3480.90

3968.38

P – only one parking per tour

M - number of tours

CONCLUSIONS

• The visiting frequency should be as long as possible (3 days)

• A strategy where trailers are used as mobile depot are superior to only using single trucks

• Tours in the local neighborhood of the plant can be served by a single truck without a trailer

CONCLUSIONS

• When the total capacity is equal, a large truck with a smaller trailer is better than the opposite

• The possible use of more than one parking place on a tour can improve the solution quality significantly

• The advantage of extending the visiting frequency increases with the size of the vehicle

Objective Function

• Driving distance

• Vehicle acquisition cost

• Ferry / toll roads

• Extension

– Cost of changing cooling tanks

– Pay for driver (overtime, Sunday, etc.)

What to determine?

• Build an initial solution

– How to determine optimal fleet mix?

– How to decide number of clusters?

– How to find seeding customers?

– When stop clustering?

– How to assign clusters to depots?

Cluster

• The process of grouping a set of customers into classes of similar/dissimilar customers.

• What criteria should be used for clustering?

• How it can be done?

• Is it good to use clustering approach?

How to cluster suppliers?

Proposed Methodology 1/3

• Cluster according to municipalities.

• Calculate demand for each cluster.

• Calculate number and types of vehicles needed for each cluster.

• Calculate distances between clusters and from/to depots.

• Merge two clusters if possible.

Proposed Methodology 2/3

• Sort clusters according to each depot.

• Find the most closest depot.

• Allocate further away cluster to this depot.

– Minimize usage of ferry/toll.

Proposed Methodology 3/3

• Main Methodology

– Tabu Search, Iterated Local Search,

Guided Local Search

• Try to find appropriate fleet mix using Shrinking and Expanding Heuristic.

EXAMPLE OF A TOUR

A

B