1. - Dynardo GmbH

advertisement

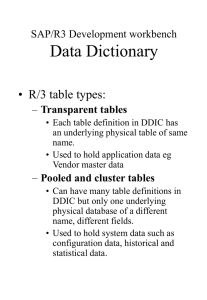

Sensitivty Analysis, Optimization and Robust Design with optiSLang and ANSYS Workbench (ANSYS v13) Optimization of a bearing angle Dipl.-Ing. (FH) Andreas Veiz Dynamic Software and Engineering GmbH, Weimar, Germany Seminar 23.-24.5.2011, Weimar Agenda • 1. Model background • 2. ANSYS workbench simulation • Parametrization of the Geometry Values • Setting boundary conditions in ANSYS Workbench • Meshing in ANSYS Workbench • Solver settings in ANSYS Workbench • Parametrization of simulation results • ANSYS Parameter Manager • 3. Introduction in optiPlug • Workaround optiPlug and optiSLang • File system in optiSLang created by optiPlug • Exporting the simulation to optiSLang • Default settings • Special features of optiPlug Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench Agenda • • • • • 4. Performing of a sensitivity analysis (DoE) • Checking the parametrization in optiSLang • Updating the parameter range • Starting a new Design of Experiments • Postprocessing of the sensitivity study 5. The Metamodel of optimal prognosis (MoP) 6. Optimization of the model • Reducing the number of necessary parameters • Defining an suitable obective function • Optimization of the model with the method of adaptive response surfaces • Read-in the best design in ANSYS Workbench • Introduction in other optimization algorithms 7. Basics of a robustness analysis • Stochastic scatter of parameters • Write out a new robustness task with optiPlug • Update the parametrization for a robustness analysis 8. Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 1. Model background • The bearing angle is part of a test bench for chains. • In this test bench, a load of 12.6 kN is set on chains. • The load is set in longitudinal direction. • A load cell is fixed to the angle. This measures the load and send it to the computer system • Therefore the whole load of 12.6 kN is set on the winding, where the load cell is fixed to the bearing angle • Thus, the problematic variables are the v.Mises stress in the whole structure and especially at the connection between the rib and the angle short below the winding. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 1. Model background • Workflow of a robust design optimization Basic design Sensitivity analysis Optimization Robustness analysis Is the design robust ? No Yes Robust design Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2. ANSYS Workbench simulation • 1. Model background • 2. ANSYS workbench simulation • Parametrization of the Geometry Values • Setting boundary conditions in ANSYS Workbench • Meshing in ANSYS Workbench • Solver settings in ANSYS Workbench • Parametrization of simulation results • ANSYS Parameter Manager • 3. optiPlug • 4. Sensitivity analysis • 5. Optimization • 6. Robustness analysis • 7. Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.1 CAE Integration within ANSYS Workbench Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.1 Overview – Parametrization in ANSYS Workbench • The basic of the parametrization in ANSYS is the Parameter Set on the project page: • Geometryparameters (from CAD or Design Modeler) • Materialparameters/ Simulationparameters • Simulationresults Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.1 Overview – Parametrization in ANSYS Workbench • The Parameter section summarizes the Parameters of each component • CAD Parameters: CAD System (external) or ANSYS Design Modeler • Material Parameter: Engineering Data • Simulation results: Simulation Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • Start a new project in ANSYS Workbench • Create a new „Static Structural (ANSYS)“ analysis Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • Attach the geometry file „angle.agdb“ to the project • The geometry is already prepared but not yet parametrized Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • To complete the parametrization, right-click on the geometry and select „Edit“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • Mark the single parameters by clicking in the checkbox. • The parameter dialog opens. • Insert a reasonable parameter name. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • Parametrized dimension appear yellow in you model • After defining the parameter name, a „D“ appears in the checkbox • Repeat this also for extrusions and blends Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • Repeat this procedure for all of your desired parameters: • XY_plane sketch 2: • H14: DS_Rib_length • H5: DS_Blade_thickness_vertical • H6: DS_Blade_length_horizontal • V7: DS_Blade_thickness_horizontal • V8: DS_Blade_length_vertical • XY_plane sketch 3: • V12: DS_Rib_height • Extrude1: DS_Blade_breadth • Extrude2: DS_Rib_breadth • Outer_blend: DS_Outer_Blend • Blend_Fixing: DS_Blend_Fixing • Blend_Bore: DS_Blend_Bore • Rib_Blend: DS_Rib_Blend • Edge_Blend: DS_Edge_Blend Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • For the blade and Rib-breadth we have to do a modification, because of symmetry • 1. Open the parameter section of the Design Modeler • 2. Double the value of the parameter „ DS_Blade_breadth“ and „ DS_Rib_breadth“ in „Design Parameters“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.2 Parametrization of the geometry • 3. Now click on „Parameter/Dimension Assignments“: Here, you can modify each of the parameters so that they depend another parameters. You may also insert formulas here. • 4. Modifiy the dimension assignment so that the value of the parameter is divided by 2. • 5. You can check your parametrization easily by clicking on „Check“. • Save the project as Angle_v12 locate in a local directory. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • Close the design modeler and start a new simulation by click RMB on „Model“ and select „Edit“. • See the „Parameter Set“ Box. This indicates that you are working with parameters in ANSYS Workbench. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • Make sure that the units are switched to „mm, kg, N, °C, s“ • Insert a Refinement with a ratio of 2 on the shown faces. • The highest stress level is expected here. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • Set the other Mesh settings like shown below • Generate the Mesh Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • Now, stet up the static structural analysis settings • Put a fixed support on the 4 holes. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • In addition to that set a displacement of „0“ in Y-Direction on the ground plate. This prevents the structure to lift from the imaginary bearing Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • Set a force in negative X-direction with a magnitude of 12.6 kN on the winding • As results, we need the total deformation and the equivalent Stress click solve Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results Stress: 133.44 MPa Deformation: 0.0836 mm Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • For the following analysis we need 3 simulations parameters: • Mass (material: structural steel) • Maximum deformation • Maximum equivalent stress • Parametrization just by clicking in the checkbox in the outline tree. A „P“ indicates a successful parametrization Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • Save the project and close the mechanical simulation. • Check the parametrization by opening the parameter section by doubleclicking on „Parameter Set“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.3 Simulation and parametrization of the results • The parameters are listet like in an Excel Sheet Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 2.4 Summary Simulation • The geometrie has been opened and parametrized • Static-structural analysis with parametrized results • Calculation time is about 1.5 min • Check of the parametrization in the parameter set • Save now the project. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3. optiPlug • 1. Model background • 2. ANSYS workbench simulation • 3. optiPlug • 3.1. Introduction • 3.2. File system optiPlug - optiSLang • 3.3. Export an ANSYS project to optiSLang • 3.4. Export the project bearing angle to optiSLang • 4. Sensitivity analysis • 5. Optimization • 6. Robustness analysis • 7. Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.1 Introduction • Bidirektional Interface between optiSLang and ANYS Workbench. • Extraction of results and input of external input-parameters to the ANSYS parametermanager • Starting of the Workbench using Python-skripts (ANSYS v12/13), former by Java-scripting (ANSYS v11) • optiPlug is now located on the project page in ANSYS Workbench, therefore it is now possible to cope with different simulation types in one optiSLang project! • Basic feature is to write the optiSLang input and output file and generates pre-defined basic workflows. • optiPlug generates the complicated starting script for starting the workbench automatically by optiSLang Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.1 Introduction Preparings in ANSYS workbench: • Definition of all parameters (design-, material-, simulation parameters) in ANSYS Workbench • Save your project. Settings in optiPlug • Choose the analysis type (optimization / stochastic) • Default settings optiSLang • Modification of the variation space • Definition of objectives and constraints • Execution of the desired optimization / analysis runs Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.2 File system optiSLang - optiPlug • optiPlug saves the files into a subdirectory of your ANSYSproject directory: • bin – folder: here is the starting script located • opti_problems: here is the input and output file and the problem file located • workflows: here you can find all the executed workflows in XML format • logfiles: logfiles of optiSLang runs • The projectfile *.fgpr Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.2 File system optiSLang - optiPlug • Files in the folder opti_problems: • Angle_v12_doe.pro: problemdefinition In the subfolder: • Angle_v12_doe.dat : all input variables are saved in an ASCII format text file • Angle_v12_doe.dat : all output variables are saved in an ASCII format text file • The name is according to your ANSYS project file name Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.3 Export an ANSYS project to optiSLang • Start optiPlug by clicking on the „optiPlug“ Button on the project page. • Then, the optiPlug dialogue opens. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.3 Export an ANSYS project to optiSLang • Overview optiPlug Dialogue: • Write or read • Problem type • Stochastic • Optimization • Start Variations space • Modify/overwrite of an existing optiSLang project • Save ANSYS Data* • Show ANSYS GUI * If you choose this option, make sure that you have enogh space on your harddrive for storaging a large amount of data Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.3 Export an ANSYS project to optiSLang • Default settings: • Parameter range defaults: • +/- 20% for Optimizationproblems, (suitable for first basic simulations) • Coefficient of variation of 5% for stochastic analysis, standard deviation 1σ • Update mode: - Warn if the optiSLang files already exist - Update the existing files - Overwrite everything Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3.4 Export the project bearing angle to optiSLang • Click on the optiPlug Button to export the project. • The export dialogue opens. • You do not need to make any changes here. • Confirm the export with OK. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4. Sensitivity analysis • • • • 1. 2. 3. 4. • • • • • • • • 5. • 6. • 7. Model background ANSYS workbench simulation optiPlug Sensitivity analysis – Design of Experiments (DoE) 4.1 Introduction – Sensitivity analysis 4.2 Import the project bearing angle 4.3 Modification of the parameter settings 4.4 Sampling 4.5 Performing a sensitivity analysis 4.6 Postprocessing of a sensitivity analysis 4.7 Summary Optimization Robustness analysis Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.1 Introduction – Sensitivity analysis Sensitivity analysis Analysis of parameter sensitivity means investigating the effect of variability of certain parameters on the variability of design-relevant response quantities. Using stochastic sampling methods such as plain Monte Carlo simulation latin hypercube sampling with statistics to evaluation for sensitivity calculation: histogram, anthill plots linear and quadratic correlation coefficients correlation matrix, confidence intervals principal component analysis detection of most sensitive/relevant input variables Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.2 Import the project bearing angle • Start optiSLang • To import the project that you created with optiPlug, click on „flowGuide“ and choose the „Project manager“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.2 Import the project bearing angle • Now, choose „Import project“ • Browsen for the project by clicking on the button • Choose the flowGuide project file xyz.fgpr in the defined directory and confirm the selection with „Select“ • Conform the creation of the project with „Apply“ and close the Project Manager with „Close“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.3 Modification of the parameter settings • Now, we have to modify the variation space of each Parameter. • To do this, choose the current project and double-click on „Parametrize_problem“ then choose the predefined „…_modify_1“ workflow. • Confirm with „Start“ to start the parametrization. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.3 Modification of the parameter settings • Unfold the parameter tree by clicking „Tree“ „Unfold Tree“ • To modify a parameter, double-click on it in the unfolded parameter tree • Alternative: right mouse button on one parameter and select „Show Dialog“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.3 Modification of the parameter settings • In the „Parameter Settings“-dialogue all of parameter settings are listed • Modify at „Optimization“ the lower and upper bounds for the parameter as shown below • Format type and parameter type are already correctly predefined. • Click on „OK“ to close the „Parameter Settings“-dialogue. • „Go to parameter“ causes a jump of a marker to the parameter in the input / output file. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.3 Modification of the parameter settings • • • Modify the lower and upper bounds of all parameters according to the tabular. The variation of the blends will remain on the default setting of +/- 10% as predefined with optiPlug We have got 13 design paramters to deal with in our sensitivity analysis Reference value Variation space DS_Blade_thickness_vertical 24 (15-30) DS_Blade_length_horizontal 180 (150-200) DS_Blade_thickness_horizontal 20 (15-25) DS_Blade_length_vertikal 160 (140-170) DS_Rib_height 90 (50-90) DS_Blade_breadth 80 (60-100) DS_Rib_breadth 15 (7-20) DS_Rib_length 40 (10-100) DS_Blend_Edge 3 -- DS_Blend_Rib 3 -- DS_Blend_Bore 1 -- DS_Blend_fixing 1 -- DS_Outer_blend 1.5 -- Parametername Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.3 Modification of the parameter settings • • To close the parametrization, click on „File“ „Exit“ Confirm the following dialogue boxes with „Yes“ and „OK“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.3 Modification of the parameter settings • • • • • Finally, you get a table of all you parameters and lower and upper bounds. Please check your parametrization carefully. You can also make final changes here Close the table with „OK“. Now the parametrization is finished. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.4.3 Sampling Summary • State-of-the-art of today is to generate the samples by Latin Hypercube Sampling in a DoE! • In our case, we have about 5075 Samples for a DoE • Because of the future meta modeling, we’ll choose 75 designs Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.5 Performing a sensitivity analysis • The Workflow of a sensitivity analysis has been predefined by optiPlug • Already filled in: •Worflow Identificator (Name) •Problem specification file (Parametrization) •Start script (by optiPlug) • Start the DoE by clicking on “Start” • Now the DoE dialogue opens Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.5 Performing a sensitivity analysis • Choose “advanced latin hypercube” as sampling method • Definine the desired number of designs to calculate (e.g. 75) • Confirm with “Apply” Then, all of the designs will be created 75 • Start the DoE with “OK” Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.5 Performing a sensitivity analysis • The sampling overview window opens. In this design overview, you can determine correlations between input parameters and check the distribution of the parameters. • In a good sampling, you will only see green boxes in the linear correlation matrix. • Start now the DoE by click on “Continue” and confirm with “Yes” Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6 Postprocessing • To start the postprocessing, you have to define a postprocessing workflow • Double-click on “Result monitoring” • Browse for the desired “*.bin” file in the related directory • Select ist and start the postprocessing with “start” Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.1 Postprocessing of a sensitivity analysis - overview The postprocessing of a DoE gives us the following results: •Correlation matrix – linear and quadratic: •Shows correlations (strong and weak) between: Input-Input, Input-Output und Output-Output •Coefficients: •Coefficient of Determination (CoD) •Coefficient of Importance (CoI) – Importance of a parameter •Regarding the CoD / CoI also leads us to reduce the parameter space by determining and deactivating unimportant parameters •Linear correlationcoefficient – correlation between parameters •Principal Component Analysis: •Another way to display the relation between inputs and outputs •Histograms: •Scatter of the parameters. It is also possible to determine areas of failed designs / critical areas •Anthill plots: •Graphical illustration of the design space of two (2D) or three (3D) parameters Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • First, have a look at the linear correlation matrix • And the confidence levels for 0.7(-0.04 0.03) and 0.5(-0.06 0.05) • Green stands for few / no correlation • Orange - red: strong positive correlation • Light-blue – darkblue: strong negative correlation • The first impression, we got from here is that we have only few but strong correlations between some input parameters and the output parameters • Now we have a detailed look at the Coefficients of Importance Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • • • • Coefficient of determination (R²) is excellent The model can be described completely with linear relations 2 parameters a large influence on the mass Dominating parameter: DS_Blade_breadth Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • Have a look at this correlation in the anthill plot: • Click in the linear correlationmatrix on the box which indicates the highest correlation between input and output • Alternative: Select the parameters in the pull-down menu Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • Strong correlation between the parameter DS_blade_Breadth and the Mass becomes quite clearly regarding the anthill plot. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • Coefficient of determination (R²) is very good • We can determine 2 parameters with a large influence on the stress • Most important parameter here is: DS_Blade_thickness_vertical Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • A Quadratic correlation becomes also evident regarding the anthill plots of the stress. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • To calculate the COI with respect to this monotonic nonlinear behavior we use the rank order transformation via Spearman correlation. • The COI will increase. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results • Coefficient of Importance (R²) is also quite good • 2 Parameters have a large influence on the deformation • Most important parameter here also is: DS_Blade_thickness_vertical Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.6.2 Postprocessing – Evaluation of the results Mass Influence DS_Blade_breadth 54% DS_Bladethickness_vertical 17% Stress DS_Bladethickness_vertical 42% DS_Rib_height 34% Deformation DS_Bladethickness_vertical 42% DS_Rib_height 22% • Table – most important parameters • These parameters will be optimized now. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 4.7 Sensitivity analysis - summary • A sensitivity analysis leads us to a better understanding of the correlations in our model. • We could specify the connections between the parameters in a detailed way. • We were able to determine the most important parameters in our model. • Therefore, the number of parameters could be reduced to three: • DS_Blade_breadth • DS_Bladethickness_vertical • DS_Rib_height • As a result, we can apply an effective direct optimization method that can deal perfectly with a limited number of parameters – the adaptive response surface method. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6. Metamodel of optimal Prognosis – MoP and CoP • • • • • • 1. 2. 3. 4. 5. 6. • • • • • 7. • 8. • 9. Background The ANSYS Workbench Simulation Using the Workbench plug-in optiPlug Getting started in optiSLang The sensitivity analysis Metamodel of optimal Prognosis – MoP and CoP 6.1 Metamodeling 6.2 The Coefficient of Prognosis 6.3 The Approximation Window 6.4 Summary and conclusion of Meta-Modeling with CoP Introduction into optimization Methods The Robustness analysis Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5 Metamodeling – the Metamodel of optimal Prognosis • A meta model uses the pre-calculated designs of a sensitivity analysis. • A defined part of these support points will be used to describe a global response surface. • This surface is fixed with the latest methods of Moving Least Squares to fit the whole variation space as good as possible. • Usually 2/3 of the support points is used to generate the response surface – the other third of support points is uses to test the approximaztion regarding the fitness. • As a result, you will get a Coefficient of Prognosis that will give you a overview how good your model is to describe it • Furthermore, you can start an optimization run on this meta model that is much more fast than FE-solver runs. • Be aware that a meta model is only a fitness. There are some highly non-linear problems that cannot be optimized with meta models. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.1 The MoP Workflow • Start a Metamodel of optimal Prognosis Workflow. • As Sample File, choose the Save*.bin file of the DoE • As Problem File, use the DoE Problem file. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.1 The MoP Workflow • Keep the standard settings for this run • Start the analysis by clicking on „OK“ – it will only take a few seconds. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.2 The Coefficient of Prognosis • The Postprocessing is the looking the same like after the DoE • Click on an output file to have a look at the CoP • You see here that the order of the important parameters is the same as in the CoI • A CoP Value of 98% is an excellent value Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.2 The Coefficient of Prognosis • Now, take a look at the CoP of the stress. • You see here that the order of the important parameters is similar to the CoI. • A CoP Value of 94% is an very good value Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.2 The Coefficient of Prognosis • Now, take a look at the CoP of the deformation. • You see here that the order of the important parameters is similar to the CoI. • A CoP Value of 97% is an excellent value Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.3 The Approximation window • Reload the postprocessing as „Approximation“ • Have a look at the approximation window of the output parameter „mass“ vs. their two most influating inputs. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 5.4 Summary and conclusion of Meta-Modeling with CoP • The CoP of our model shows that in this case we can get excellent results by having a Moving Least Squares approximation in the design space. • The precondition is that we have a good sampling with fulfilled confidence cirteria. • In this case we can save a lot of time by performing an optimization run on the meta model. • An optimization on a meta model may give you some first hints of you possible optimization space. • Be aware that a meta model cannot replace the FE-runs in every application. Optimization on meta models can be very quick in some applications but a calculated best design can be quite different from the result of a meta model. So handle optimization runs with care. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6. Optimization • • • • • • 1. 2. 3. 4. 5. 6. • • • • • • 6. • 7. Modelbackground ANSYS workbench simulation optiPlug Sensitivity analysis – Design of Experiments (DoE) Metamodel of optimal prognosis (MoP) Optimization 6.1 Definition of objectives and constraints 6.2 Optimization using the Metamodel of optimal prognosis 6.3 Direct optimization using FE solver calls 6.4 Read-in the optimized model in ANSYS Workbench 6.5 Summary Robustness analysis Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6. Multidisciplinary Optimization with optiSLang CAD and CAE Parameter definition Sensitivity study – identify the most important parameters and check variation/COD of response values minimize Validate optimized design in CAE and CAD Define optimization goal and optimize Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6. Optimization • After performing a sensitivity analysis we take the won knowledge to optimize our model. • The optimization improves a model due to defined objectives. • If you choose the right end conditions, you always get a better model during an optimization. • According to the desired optimization aim, you can choose the suitable algorithm. • An optimization can include several objectives, some even can deal with conflicting objectives • After optimizing a model, it has usually be checked concerning its robustness against small variations, e.g. tolerances. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • You can use the predefined problem file of the sensitivity analysis for the optimization • Necessary modifications: • Deaktivate the unimportant parameters • Define a suitable Objective • Include Constraints if necessary • Our optimization should follow the following aim: • Reduce the mass • The equivalent stress should not exceed 225 MPa. • We use a compromise result as start solution for optimization • In this case design XX Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • To adapt the problem-files chose “Parametrize Problem” in optiSLang and click on “create a copy and modify it”. • Browse for the predefined File of the sensitivity with and insert a new name (without path!) and • Choose reference design • confirm with “Start”. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • Define the best design of the sensitivity analysis as reference design • In this case: Design 13 Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • Creating an objective: • Double-click on “Objective section”. • Set a suitable name for the objective and click on “New”. • Now insert the name of the term (Attention: The name mustn’t be identical to any another name!). • As a funktion insert the parameter that has to be minimized. In this case it is “Volumenkoerper_mass” Confirm it with “Enter”. • Close the dialogue with “OK” Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • • • • Creating a boundary condition – a stress-constraint: double-click on “Constraint section” click on “New” at “Inequality 0<=“ The formula of the constraint is: 0<= 225 – Equivalent_Stress_Maximum • Insert the name (Attention: not identical to any other name) • As a constraint, insert the following formula: 225-Equivalent_Stress… and confirm with Enter. • Close the dialogue with “OK” Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • Save the tree and exit the parametrization. • In the overview table, set the unimportant parameters as constant by clicking in the constant checkbox. • Set the parameters shown right as constant. • • • • 3 parameters remain active: DS_Bladethickness_vertikal DS_Blade_breadth DS_Rib_height Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.1 Definition of objectives and constraints • Now we have: • Deactivated the unimportant parameters • Defined a suitable objective • Defined a necessary constraint • Click through the different cards to check you settings • Close the Parametrization with “OK” and confirm any changings. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2 Optimization using the MoP • If a sensitivity Analysis is performed before and a Metamodel of optimal Prognosis was done, it is recommended to do the first optimization on this meta model. • The reason is quite simple – if the response surface is good enough (take a look at the Coefficient of Prognosis) an optimal performance can be expected. • The big advantage is that no solver run is done during the optimization – the only solver run is the recalculation of the best design in the end. • Be aware, that the MoP as a solver does not work properly for the extreme values of the parameters nearby the lower or upper bound. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2.1 Evolutionary algorithm (EA) using MoP 2a. 1. 2b. 2c. 3. 1. Start a new Nature inspired optimization workflow 2. Define workflow name, workflow identifier and problem file name 3. Select Evolutionary Algorithm (EA) – global search as algorithm Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2.1 Evolutionary algorithm (EA) using MoP 1. 2. 3. 1. Use MoP as solver and choose the MoP data file from sensitivity 2. Enter solver call (Maxwell_Batch.bat) to verify best design 3. Start NOA workflow Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2.1 Evolutionary algorithm (EA) using MoP 1. 1. Choose start population size 2. Keep defaults for Selection, Crossover and Mutation Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2.1 Evolutionary algorithm (EA) using MoP 2. 1. 3. 5. 4. 1. 2. 3. 4. 5. Objective history for each design Best design input parameters Best design response data Penalized objective and constraints data Parameter history for each design, new generations are marked Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2.1 Evolutionary algorithm (EA) using MoP 3. 1. 3. 2. 1. Objective history and response data shows again a quite large difference between the approximated and the real values. 2. Input Data shows, that the parameters touched their borders. 3. The Stress constraint is violated by 2,8% Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.2 Optimization using the MoP - Summary • Using the MoP as a base for the Solver, optiSLang was able to generate better designs than the sensitivity analysis in each different way but because of the violation of the stress constraint, these designs can only be taken as a starting point of a design improvement. Analysis Type Initial Design Sensitivity Analysis Evolutionary Algorithm (EA) on MoP Simple Design Improvement (SDI) on MoP Stress 141.014 MPa 182.918 MPa 231.355 MPa 236.406 MPa Mass 4.89 Kg 3.181 kg 2.5772 kg 2.577 kg Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3 Direct optimization • The other way of optimizing a Model is using the direct optimization – that means that each desing is calculated in a solver run. • The advantage is that the final performance of the best design is often better than using the MoP response surface. • It is necessary to use it when the MoP shows only a weak quality of prognosis. • It is recommended if you are working with signals because the optimization on MoP does not deal with signals. • Be aware that the total calculation time is much longer. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3 Optimization with adaptive response surface methods • • • • ARSM provides a local linearization (local DoE) in the design space. Therefore for each subspace of our 3 Parameters, only 6 design points are necessary if we choose the D-optimal linear scheme for the local DoE Usually, the ARSM converges after 10-20 iterations. So we need 100 – 200 FE-Simulations Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.1 Setup the ARSM • Start the ARSM Workflow by a double-click on Adaptive_... • Set a Workflow Identificator (Name) • Browse for the adapted problem file with Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.1 Setup the ARSM • Choose „Run a script file“ and browsen with for the start script in the \bin folder of your project or copy it from the DoE dialogue. • Choose the number of parallel runs and idle time according to your hardware. • Start the ARSM with „Start“. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.1 Setup the ARSM • You can now make some expert settings. • It is recommended to set the option „recycle previous support points“ to make the optimization more robust at the parameter bounds. • Click „OK“ to start the optimization. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.2 Postprocessing ARSM 2. 1. 4. 1. 2. 3. 4. 5. 5. Objective history for each design Best design input parameters Best design response data Penalized objective and constraints data Parameter history for each design Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 3. 6.3.2 Postprocessing ARSM • 1. Iteration History: • Here you can see the history of your objective for each iteration • As it is indicated there are soe occurances of failed designs. This longers the whole optimization process. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.2 Postprocessing ARSM • 2. Response Data: • Here you can see the results (outputs) of your design. • As default the best design is chosen, so that you can now get an information how much the algorithm could improve your model. • The stress constraint is not violated! Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.2 Postprocessing ARSM • 3. Design Parameter: • These are the CAD parameter values of your optimization. • The default setting is also the best design. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.3.2 Summary ARSM • Performing an optimization with ARSM, a significant design improvement could be achieved. • The mass was reduced by 48 % from 4.89 to 2.57 kg • The stress increased by um 69 % to 225 MPa. • The stress remains in the given constraints • Therefore we can say that regarding the boundary conditions, the part has now been optimized as good as possible. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.4 Read-in the optimized model in ANSYS Workbench • Now we want to read in our best design in Workbench to have a look at the geometry and for further analysis. • To do this, just open the project and simulation in workbench again. • The geometry read-in will be done by clicking on the optiPlug button on the project page. • Now, the optiPlug dialogue opens again. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.4 Read-in the optimized model in ANSYS Workbench • Select „Read calculated design“ • Browse for the correct best design • In our case it is the Design 219 (this is different usually for each optimization run!) and confirm your selection. • If you want to calculate your model again, just update the results Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.4 Read-in the optimized model in ANSYS Workbench • Calculating the results of the optimized design Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.5 Summary optimization 1. In optiSLang, you have always two different approaches to optimize your task. 2. If you did a sensitivity analysis including a Meta Model it is recommended to use this Meta Model for a first optimization run. You may not get the absolute best design but it is usually better that your start design. 3. One of the big advantages is the minimal time that is used. You only have to recalculate 1 design – the best design instead of several hundreds. 4. The quality of the MoP optimization depends directly on the quality of the basic meta model. That means – the higher the Coefficient of Prognosis of the meta model – the better the optimization result will be. 5. Parallel to that it is possible to use a direct approach for optimizing. There, the direct outputs of a FEA are used. So the quality of the optimization is usually better but takes much more time because you have to calculate each design. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.5 Summary optimization • • • • Overview of the different optimization approaches. It becomes evident that using the MoP solver, it is possible to reach a quite good design, but you have to check the constraint fullfillment The combination of sensitivity analysis, MoP and Optimization on the generated response surface shows an optimal relation of performance and calculation time. The ARSM optimization leads to the absolute best design in an affordable period of time. Initial Design Sensitivity Analysis EA (MoP) ARSM (direct) Max Stress 141 MPa 182.9 MPa 231.4 MPa 222.3 MPa Mass 4.89 Kg 3.181 kg 2.5772 kg 2.57 kg Calculated designs 1 75 75 + 1 (Σ=76) 75 + 250 (Σ=325) Calculation time 1.3 min 95 min 97 min 420 min Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 6.5 Summary Optimization • The different optimization approaches on their response surfaces: ARSM (global) EA (MoP) • A very large area on the response surface is used for the EA on MoP. • This depends also on the start values given from sensitivty. • The used area on the global response surface for the direct optimization is much smaller. This depends on the ARSM start setting of the start range Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7. The robustness analysis • • • • • • • 1. 2. 3. 4. 5. 6. 7. • • • • • 8. Background The ANSYS Workbench Simulation Using the Workbench plug-in optiPlug Getting started in optiSLang The sensitivity analysis Metamodel of optimal Prognosis – MoP and CoP The robustness analysis 7.1 Introduction into robust design / design for six sigma 7.2 Exporting the files for a robustness analysis 7.3 Performing a robustness analysis 7.4 Postprocessing of a robustness analysis Summary and conclusion Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.1 Introduction into robust design / design for six sigma • The product robustness is one of the most important tasks for “optimizing” the performance of a product. • The proof of robustness with variation or probability measurements requires a probabilistic analysis. • It determines Safety and reliability for 1 & 2 (3) Sigma levels and identifies the most sensitive stochastic variables. A higher sigma level is also possible by performing a reliability analysis • State of the art, possible with high number of stochastic variables can be analyzed by a relatively small number of necessary FEsimulations due to sophisticated sampling. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.1 Introduction into robust design / design for six sigma • Six Sigma is a concept to optimize the manufacturing processes such that automatically parts conforming to six sigma quality are produced • Design for Six Sigma is a concept to optimize the design such that the parts conform to six sigma quality, i.e. quality and reliability are explicit optimization goals • Because not only 6 Sigma values have to be used as measurement for a robust design, we use the more general classification Robust Design Optimization Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.2 Exporting the files for a robustness analysis • We have to add the material parameters and a the force as additional parameters for the robustness analysis • First open the engineering data to parametrize the material: Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.2 Exporting the files for a robustness analysis • Now, open the simulation and parametrize the force Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.2 Exporting the files for a robustness analysis • • • • • Save the ANSYS Project (e.g. as Angle_robust) Click on the optiPlug export button This time, choose „Stochastic problem“ Set the Coefficient of variation to 2.5 and click OK The robustness workflow and parametrization is automatically added to the existing project Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.3 Performing a robustness analysis • Open the predefined robustness workflow. • Set the number of designs to 75 and the Sampling method to „Advanced LHS: minimal linear correlation“ Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.4 Postprocessing of a robustness analysis • Start the calculations. • Open the generated resultfile after the analysis has finished. • Click on the outputvalue of the maximum stress. This will be our indicator for a robust design. • We will add now a limit to see, how robust the optimum design regarding a maximum stress will be. • Click on the Marker „Set limit“ in the main Window of the postprocessing and type a 250 (that is the maximum tensile stress of strutural steel: 250 MPa) as a limit. • We will now get the probability that a design has a larger maximum stress than the limit. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.4 Postprocessing of a robust analysis • Taking a look at the histogramm, we see that we have a probability of 56% that the maximum stress is below the desired limit of 250 MPa • That means, a probability of failure of 44% • To achieve a much lower probability of failure, it is necessary to re-run an optimization with a lower max-stress condition! Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.4 Postprocessing of a robust analysis • Another Information, we get from the result of a robustness analysis is the variation of the output variable in correlation to the input variables. • In this case, we see that the maximum stress varies +/- 13.2% • As in the sensitivity analysis, we also get the most important parameters Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.4 Postprocessing of a robust analysis • Take a look at the Histogramm of the mass • The mass varies between 2.3 and 2.85 kg, that means 4,2% • So the variation of the mass is double than the variation of each input (2.5%) • The highest mass is still lower than of the best design of the sensitivity analysis in the beginning. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.4 Postprocessing of a robust analysis • Take a look at the Histogramm of the deformation • The mass varies between 0.3 and 0.55 kg, that means 12%! • So the variation of the mass is four times higher than the variation of each input (2.5%) Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.4.1 MoP after a robust analysis • Run a MoP Analysis on the robustness result • Get the CoP and the response surface of the critical value „Stress“. • The rather low CoP of 74% indicates noise effects of the solver to the result or maybe mesh influence. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.5 Conclusion of the first robust analysis • The robustness analysis gives us the possibility to analyse the variation of the output variables in correlation to small input variation. • The more stable the structure is after an optimization or in the beginning, the smaller these variations of the output variables are. • The variation of the responses is two or four times higher than of the input variables. This indicates that with a variation of 2.5%, we will have to high variations of the responses. • We also get to know, how many of the designs would fail by setting a limit. Because of a rather small number of designs, this probability is more an overview. • To get a robust design, it is now necessary to re-run another optimization. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.6 Roust Design Optimization Iteration II • To achieve a design that is either optimized and also robust, it was now necessary to start another optimization run. • Set the output constraint for the stress now to 200 MPa and start an ARSM optimization run with this edited problem definition. • The total mass was reduced by 29% to 3.07 kg. • The maximum stress is now 200 MPa. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 7.6 Roust Design Optimization Iteration II • Take the new optimized Design now into a robustness analysis. • We will now get a more robust design • The percentage of Designs that will fail is now ~12% instead of >44%. • To get a design that will cause no failure, it would be necessary to start more iterations. • The rather low CoP of 76% indicates noise effects of the solver to the result or maybe mesh influence. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench 8 Summary • During this seminar, we got the basic analyisis settings in optiSLang. • The Workflow of a simple robust design optimization was shown here. • In the beginning, the most important parameters are determined. • Then, an optimization run was set-up and we got an optimum. • In a robustness analysis, we saw that we got several designs, that violat the material limit and we got a rather large variaton of the output variable „max-stress“ • Next step was to re-run the optimization and robustness flow until the robust criterias are fullfilled. Sensitivity analysis, optimization and robust design with optiSLang and ANSYS Workbench