“Make to order or Make to Stock Model and Application” S

advertisement

“Make to order or Make to

Stock Model: and Application”

S.Rajagopalan

By: ÖNCÜ HAZIR

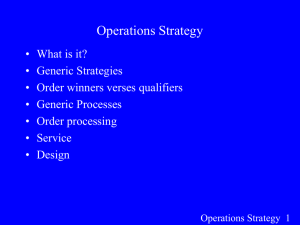

Content of Presentation

Introduction

Literature Review

Assumptions

Trade-offs and Congestion Effects

General Model and Relaxed Model

Properties of Optimal Solution & Solution

Procedure

Computational Study

Experimental Insights

Introduction

Motivation is to determine whether an item is

to make to stock(MTS) or make to order(MTO)

and to offer an inventory policy for the make to

stock items.

Characteristics of the production environment is

multiple items,limited capacity and setups

between the production of consecutive items.

Objective is minimize inventory costs of MTS

items while ensuring that orders for MTO items

are fullfilled with a sepicified probability.

Literature Review

Popp(1965) made cost comparisons to make

an item MTO or MTS for a single-item

stochastic inventory model.

Williams(1984) assumed lower demand items

are MTO and higher demand items as MTS.

Federgruen and Katalan(1995,1999) allowed

the interruption of MTS items when MTO

demand is realized.

Carr and Duenyas(1998) focuses on criteria

to accept or reject MTO items.

Karmakar(1987) considers the queue length

as a decision variable.

Assumptions

Stochastic stationary, uncorrelated

demand,varying processing times and limited

capacity.

No inventory is carried for MTO items.

(Q,R) inventory policy is used for MTS items.

First come first served (FCFS) queue

discipline.

Production facility is approximated by M/G/1

queue discipline.

Assumptions

Setup and processing times are deterministic.

Type 1() service level represents probability

of no stockout.

The distribution of demand during lead time is

characterized by queue time,material

handling times are ignored.

Whenever there exists a demand for MTO in

the time period,a production order is initiated

for a batch size equal to demand quantity.

Trade-offs and Congestion Effects

Making an item to order:

Decreases inventory,

Congestion effect:

More setups and

higher utilization

Longer and

variable lead

times

Higher cycle and

safety stock for

MTS and poorer

service for MTO

Making an item to stock:

Decreasing the lot size reduces cycle stock but

increases number of setups and utilization so lead

time increases.As a result more cyle and safety stock

for MTO items and poorer service for MTO items.

Model Parameters

Processing time

Number of batches per

unit time

MTS

i+qi/i

MTO

i+(i/mi)/i

i/qi

mi

General Model

Min hi (qi / 2 f i (Gi (.),Ps ))zi

ST

i

H ( E ( w), v( w), Po ) T

qi 0

zi [0,1]

E ( x )

E ( w)

2(1 )

2

τ i (E(w), v(w))

3

E

(

x

)

2

v( w) E ( w )

3(1 )

E(w) σ i v(w) μ i2

2

Model without congestion effects

Min

hi (qi / 2)

ST

i

( i ( zi / qi (1 zi )mi ) i / i ) 1

i

qi 0

zi [0,1]

Properties of optimal solution

1)If zi 1 in an opt imalsolut ion t henμ /q m and

i i

i

γ(η) 0

2)An it em is MT Sif μ /q m /2

i i

i

3)If γ (η) γ (η) and if z 1 t henz 1

k

j

k

j

h (q /2)

i i

γ (η)

j

α (m μ /q )

i i

i i

γ (η) : Savings in inventory divided by incremental capacity

j

Solution procedure

1)Set zi=1 for all i and set

= maxi {mi2ihi/2i}

2)Compute i for all items, if i <= 0 set zi=0,

arrange items in order of decreasing ratio i

3) Set zi=0 in the order determined

above.Compute lot sizes and costs, check

whether total cost declines.If cost decreases

stop.

For the heuristic with congestion effects the

ratio i includes cost of safety stock and for a

given value of zi, a non-linear program is

solved.

Application of Model

Computational Study

The heuristic performance was

evaluated relative to lower bounds.

Average percentage duality gap

between heuristic gap and lower bound

was performance criteria.

It is found that the heuristic works well.

Experimental Insights

The MTS/MTO decisions with and without

considering congestion effects were similar.

The lowest and highest demand items are

MTO medium demand items are MTS since

incremental capacity to make an item to MTO

is concave in the average demand.

In addition to items demand decision

depends on processing times,unit holding

cost and set uptime.

As size of time bucket increases, number of

MTO items increase and total cost

decreases.However customer responsiveness

decreases.