Elec467 Power Machines & Transformers

advertisement

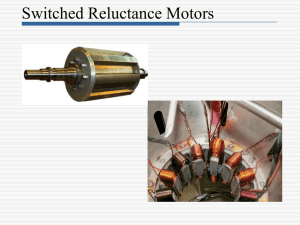

Elec467 Power Machines & Transformers Electric Machines by Hubert, Chapter 6 Topics: Single phase induction motors Single Phase inertia Single phase induction motors can not develop a rotating field nor motor torque without auxiliary methods because they only have two poles. A squirrel cage rotor locks into position and doesn’t move as seen in (a) above. The main idea is to develop a quadrature field axis by initiating rotor rotation by mechanical or other means. Quadrature Field Theory Once the rotor is moving a “quadrature” field is created at right angle to the direct axis field. It is created by the speed voltage of the rotor turning thru the existing field. The following rotor bars continue to hold the quadrature field up and the rotor picks up speed. Effect of adding a pole Starting torque is called locked rotor torque, TLR. This is the formula to calculate the torque required to start the split-phase motor. TLR ksp I mw I aw sin Variables for the split-phase motor ksp = machine constant Iaw = current in auxiliary winding Imw = current in main winding α = difference twn current phases A phase-splitter eliminates mechanical starts by initially creating the rotating field. Once the rotor starts the phase-splitter circuit can be shut down as the quadrature field takes over. Shade-pole motor This single phase motor uses a split stator with one of the forks wrapped with a copper ring that acts like a short-circuited secondary of a transformer. This secondary winding creates an mmf (that collapses) which opposes the regular field thus creating a field across the face of the stator that is irregular, stronger on one edge than the other. It sweeps across the face of the stator starting the rotor rotation when the quadrature takes over. Modifications 3Ø motor from 1Ø With a couple of capacitors, you can create a phase shift and run a three phase motor from a one phase source. This motor has a starting capacitor that adds extra capacitance to assist the starting torque. The motor should then be derated to 2/3 of the three phase rating. Elec467 Power Machines & Transformers Electric Machines by Hubert, Chapter 7 Specialty machines: Reluctance, Stepper, Linear, and Universal Salient Poles Machines such as reluctance motor and hysteresis motor are used for timing devices such as tape recorders, turntables and other device with constant speed requirements. They are an induction motor with a modified squirrel-cage rotor shaped by notches, flats or barrier slots that provide routing paths for magnetic flux to poles that are formally known as salient poles. Salient means projecting or prominent. Shaping the flux across the power gap makes this machine a reluctance machine. Reluctance Motor Reluctance formulas For a reluctance machine, at no load the centerline of the salient poles line up with the rotating field produced by the stators and rotates at synchronous ns. With increasing load the salient poles lags behind the rotating field by an angle called the torque angle, δrel, while in synchronous rotation with the field. When the angle exceeds 45°, the motor runs as an induction machine. 2 Trel K V sin 2 rel f Trel is the average value of the reluctance torque K is a constant that varies according to the machine V is the applied voltage and f is the line frequency represents the angle in electrical degrees (lower case delta) A hysteresis motor has a rotor that is a cylinder made of a permanent magnet. The operation is quite similar to the reluctance machine with a torque angle, δh. Variable-Reluctance Motors • A stepper motor is a variable-reluctance motor. • The rotor composed of salient poles. • The stator has one or more poles than the rotor. • Depending on the position of the rotor when one (or more) of the stators is energized will cause the reluctance of the magnetic path to vary. Stepper motor workings Step angle calculation Ns Nr Ns Nr 360 B = step angle in space degrees Ns = number of stator poles (also called teeth) Nr = number of rotor salient teeth Control of when the rotor steps, how fast, and in which direction can be done with a microcontroller circuit. In figure 7.7 (f) the switches are connected to output I/O pins of the embedded processor. Input would be a zero-biased potentiometer connected to an ADC input. As long as at least one stator pole is energized, the rotor would be held steady in one position thus enabling a locked position to be selected by the user. Half-step operation By turning on two of the stator poles at the same time, the rotor will be repositioned half-way between two poles in what would be called a half-step. This doubles the resolution. Further improvement in the resolution can be accomplished by incrementally increasing the current in the adjacent stator to full value where the rotor becomes position ½ between the two stators then decreasing the current in the original stator. This is called micro-stepping. Restoring torque The holding torque (static torque) seen in (a) is equal to the maximum load-torque that can be held without having the rotor slip poles. The angle when slipping poles occurs is twice the step angle. This is measured by use of a torque wrench applied to the rotor shaft. Stepper motor constructed using a permanent magnet This design allows the flux from a permanent magnet to be added to the electromagnetic flux of the stator to give added holding power. In the construction of the rotor, the toothed sections attached to either side of the permanent magnet are misaligned with each other but arranged so that just one south/north pole of the rotor will align with one north/south pole of the stator. In (a) and (c) there are ten rotor poles but for the purposes of calculating the step size there are only 5 . Linear induction motor In these diagrams, the flux field is moving to the right as seen by the two positions of Us for the same flux line. This causes a current to develop in the conducting rail such that flux bunching occurs causing a mechanical movement in the same direction as the sweeping field. Reversing the flux will cause the movement to reverse. LIM synchronous speed LIM stands for Linear Induction Motor and is one method use to implement high-speed rail lines. In the above diagram the primary is connected to the AC supply. The windings are laid in a straight line for a two-pole machine with one coil per phase per pole. The connections between poles (wye/delta) are not shown. The train would be connected to the rail. The pole pitch is the span of the coils. U s 2f Us = synchronous speed (m/s) = pole pitch (m) f = supply frequency (Hz) U U s (1 s) U = 2nd speed (m/s) s = slip s U s U Us Universal motor The rotor is called the armature that is connected in series with the stator (called series-field windings). The torque is proportional to the flux density (created by series-field windings) and the current in the armature. When the motor is running the rotor in the positions seen above is generating maximum flux with the current peaking in the rotor and the series-field windings but 90 space degrees later, the rotor isn’t cutting many flux line and the voltage is zero-crossing just as the commutators are shorted out by the brushes. Elec467 Power Machines & Transformers Electric Machines by Hubert, Chapter 8 Topic: Synchronous motors Rotor for a synchronous machine Word play: The stators for a synchronous machine are called the armature but they act exactly the same way as the stators of an induction motor. This terminology is opposite to the Universal motor just mentioned in the last chapter and DC motors. The rotor of a synchronous machine is made up of two overlapping winding: (1) like a squirrel cage winding (aka: pole-face, amortisseur, and damper) and (2) wound rotor winding (aka: excitation, magnetic, field coils, field). Salient-pole synchronous rotor When the motor is turned on the squirrel-cage winding are used to accelerate the rotor to near synchronous speed. Then the field coils on the rotor are turned on making the squirrel cage bars into an electromagnet called field poles. Shaft mounted DC exciter The field coils are powered by a DC motor attached to the shaft of the synchronous motor. The voltage is brought from the commutators of the DC motor to the slip rings of the rotor to power up the field coil. This in effect makes the rotor act like a permanent magnet and bring the motor up to synchronous speed with zero slip and a torque angle controlled by the load. Torque Angle By varying the voltage in the field coils (rotor) the power across the power gap can feed voltage back into the AC supply by the counter-emf generated by the rotor electromagnets sweeping the armature (stator) coils. Synchronous machines built expressly for this purpose have no external shafts and are called synchronous condensers that “float” on the bus. Power factor This chart allows you to estimate the armature current based on the excitation voltage (per phase) and rated load. It also lets you determine whether or not you have the machine contributing a leading or lagging power factor to the grid. Types of torque changes with power angle The power angle is changed by varying the DC current supplied to the field coils of the rotor from the DC exciter motor attached to the shaft.