Stage 1 Turbo kit instructions

advertisement

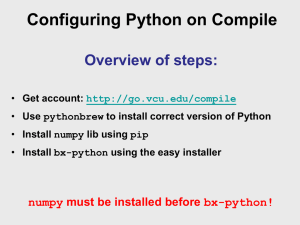

Stage 1 Turbo kit instructions 79-93 5.0 !!!This kit is for off road use only!!! This kit is NOT emissions legal!!! This kit is perfectly capable of turning your motor into a pile of scrap in 3 seconds flat! Make sure you get it properly tuned! If you do not know how to do this I suggest you contact a SCT tuner in your area. This kit will show any defects in your drive train, make sure the rest of your chassis and components are upgraded to handle the increased hp. We are not responsible for any broken parts caused by installation of this kit. READ ALL INSTRUCTIONS BEFORE STARTING ON THE VEHICAL!!! CLEAN ALL PIPING INSIDE AND OUT WITH WATER!!! THERE IS MATERIALS LEFT OVER FROM ASSEMBLY INSIDE ALL PIPES!!! WE BLOW THEM OUT BUT THEY STILL NEED CLEANED OUT RIGHT BEFORE ASSEMBLY!!!! Extra Required Materials, Not included with kits. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Copper RTV Energy suspension motor mounts for 79-93 hatchback. Shorter belt to do away with smog pump. Oil pan, upper intake and valve cover gaskets. 6 quarts of high quality oil, and oil filter. Cat back hook up. Fuel injectors Stock fuel pressure regulator is good under 550 rwhp. Fuel pump 255 lph If your car is equipped with mass air you must upgrade to a blow through mass, and use the required silicone to install. 8 spark plugs two steps colder then stock gapped at .025. 4- 3/8’s 1.25 long bolts with stainless nuts and lock washers. Teflon tape. A custom tuned chip is highly recommended. Having 2 friends to help is also very handy. Make sure you have the correct power steering line as shown in the power steering section. Section 1 Disassembly 1. Unhook the battery and remove from car. 2. Raise the vehicle. A vehicle lift comes in very handy to remove old parts and installing new. 3. Carefully unplug the o2 sensors on the h pipe as these will be needed later if your car is equipped. Remove the h pipe from the factory manifolds to the cat back. Remove the 02 sensors and set them aside they will be used later. 4. Remove the front bumper cover from the car and if the car has fog lights the fog light mounting bar must be removed. 5. Unbolt the power steering cooler if equipped and allow to hang out of the way but do not unhook the lines. 6. Remove the inner metal or fiberglass bumper (depends on the year). 7. Remove the pass side inner fender liner. 8. Label and remove the spark plug wires from the plugs. 8. Remove both factory headers / manifolds from the car. Clean any remaining gasket material from the heads. 9. Remove the serpentine belt. 10. Remove the smog pump. 11. Remove the smog tubing including the tubing crossing over the back of the motor. Use factory block offs to plug the holes in the back of the cylinder head. 12. If equipped unplug the mass air meter wiring and remove all the airfilter, mass air assembly, and rubber tube going to the throttle body. 13. Remove the upper intake (be sure to seal off the lower intake ports with duct tape so no foreign items gets in the motor). 14. Remove the pass side valve cover bolts but do not take off motor yet. Now on to the hard part the motor mounts and oil return bung. There are a few different ways to handle the oil pan bung and motor mount change. This is the fastest & easiest way. 1.Lift and support the main body of the car. 2.Remove both front tires. 3.Drain the engine oil 4.If you have upgraded your suspension to coil over suspension skip step 5 thru and including step 8. 5. Support the A-arm with a floor jack and remove the ball joint nut. 6. Using a ball joint separator jar the ball joint loose from the spindle. 7.Slowly lower floor jack and remove the coil spring. Check the brake hose and make sure it doesn’t get pulled tight if it starts to get tight remove the caliper from the spindle and support with a wire to the frame so it does not hang on the brake line. 8. Do the same for the other side. 9. Remove the bolt holding the coupler to the rack and pinion and remove the steering shaft from the rack and pinion, just let it hang. 10.At this point you will need to support the motor with either a engine support bar, or a engine crane. 11. Once the motor is safely supported remove the motor mount nuts. 12. Support the factory cross member with a jack, or two friends if they are handy. 13. Remove the 8 bolts holding the k member to the car. Lower the k member just enough to get to the motor mounts easily and all the oil pan bolts. 14. Change the motor mounts on the engine block. USE ENERGY SUSPENSION POLY MOUNTS!! 15. Remove the oil pan, and gasket from block. 16. Mark a point from the front of the oil pan 2 inches back on the passenger side of the oil pan and 1.5 inches down from the rail. 17. Measure the oil pan drain back bung that came with your kit most of them come in ¾ but we have had a few come in 7/8’s so check this before you drill. Drill a hole on the mark you made in step 16. Install the bung making sure you have the male -10 nipple to the outside of the pan. (yes, I do need to say this, it has happened). Also make sure you have one plastic washer inside and one on the outside of the pan. Add lock tight to the threaded portion and install the inner nut, tighten enough just to see the plastic washers start to smash. 18. Clean the pan out with Brake cleaner making sure you have all the metal removed and the baffle area is clean. 19. Install your oil pan gasket and oil pan in reverse order to how you removed it. 20. Reinstall your factory cross member. Make sure it is in correct, there are alignment holes directly under the strut towers, and tighten to factory torque specs. 21. Reinstall your motor mount nuts and tighten to factory specs . 22. Reinstall your steering joint to the rack (make sure it is in all the way and the bolt goes through the slot cut through the side of the shaft. Use red lock tight on the bolt. Make sure it is in correct, and tighten to factory torque specs. 23. Reinstall the ball joint nuts and use new carter pins if your ball joints use them if they are lock nuts use new ones from the factory. 24. Leave the tires off until the whole kit is on the car and you are ready to fire it up as you will end up removing and installing many times . 25. Remove and reinstall oil filter (pre fill the oil filter) 26. REMEMBER TO REFILL THE OIL PAN!! (yes I need to say this also) The hard work is over now on to the easy stuff. Section 2 Metal work. There are three areas we will need to touch on. • On mustang chassis newer then 1988 the front edge of the sway bar mounts will both need to be ground to allow the headers to bolt up and not hit. You will need ¼ of clearance on the passenger side and 1/8 on the driver side. •At this time mock up your passenger side header using just one bolt at each end of the head. You will notice that the lower back corner of the T-4 flange will hit the pinch rail, if it doesn’t hit it will still be close and the bolt wont go in. Mark the pinch rail with a marker. •At this point remove the header and bend the pinch rail in towards the motor for clearance. Some people grind this down but I do not recommend it , it is best to just bend in towards the engine bay just enough to get clearance. •Retest the header fit, if all is well, mock up the turbo and make a line in the center of the frame rail directly under the oil drain. Remove the turbo and header and check under the frame rail and make sure there is nothing you will be drilling through. Using a hole saw drill a 1 inch hole directly through the rail, make sure you go all the way through. If all is done correctly you will come through the rail just in front of the sway bar mount. If you do not want to drill through the rail, you can slightly clock the turbo so the drain is aimed towards the outside of the rail and you can drill the hole there. This is not the preferred method though and may lead to oil not draining back properly. POWER STEERING PICTURES • • It is important that you use the line shown in this picture. The fitting coming out of the pump must have the mandrel bent 90 end as shown NOT the T type. If your car is equipped with a power steering cooler it must be relocated and the lines will need to be lengthened • Section 3 wiring All wiring on the passenger side needs to be relocated out into the fender well. Section 4: Installing 1. DO NOT USE ANY GASKETS NOT EVEN THOSE VERY EXPENSIVE USELESS COPPER OR ALUMINUM GASKETS!!!!!!! 2. Lay out both headers with the flanges facing up. 3. Apply a very thin coat of copper rtv (so thin you can almost see through it) to the head flange and tack it up with your finger. Let it sit for about 5 mins then install directly on the cylinder head. Make sure you start all bolts and tighten them down evenly. If applied correctly once tight there will be a very small line of rtv squeezed out. If there is more then a pin thickness coming out from the flange you applied to much silicone and you will need to remove the header and clean it off and start over. To much is just as bad as not enough. 4. Apply one bolt from the back of the t-4 (square flange on the passenger side header) and install a nut on it to hold it into place. This should be a 3/8 bolt 1.250 inches long using stainless steel nuts will make it easier to remove later. 5. Apply a very thin coat of copper rtv (so thin you can almost see through it) to the head flange and tack it up with your finger. Let it sit for about 5 mins then install directly on the cylinder head. Make sure you start all bolts and tighten them down evenly. If applied correctly once tight there will be a very small line of rtv squeezed out. If there is more then a pin thickness coming out from the flange you applied to much silicone and you will need to remove the header and clean it off and start over. To much is just as bad as not enough. 6. Remove the nut you installed in the last step. 7. Take care on the passenger side to make sure the wires are routed and turned towards the valve cover. Spark plug insulation sleeves are very useful. It is best to use 90 degree boots and run the wires under the passenger header. 8. Reroute the power steering lines and clutch cable if necessary. Section 4: Installing Turbo 1. Before we start there are a few things you must get comfortable with on the turbo and a few things to install. 2. First thing to do is properly clock the turbo housings and center sections. Loosen the 6 bolts holding the exhaust housing (the side of the turbo made from cast iron with the rectangle flange that bolts to the header) to the center section of the turbo. This will allow you to turn the housing. 3. Slide the housing over the bolt you left in the header and square up the flange by hand or you can add a extra bolt and nut to hole it in place. 4. Turn the center and front housing of the turbo until the oil feed hole (1/8 pipe thread hole) Is straight up and down and the square oil drain hole is facing straight down towards the hole you drilled earlier. 5. Remove the turbo and tighten the exhaust housing bolts. 6. Next step is loosen the 6 bolts that hold the compressor housing and clock the housing so the outlet (2.5 inch outlet) is aimed down in between the alternator bracket and frame rail. 7. Remove the turbo and snuggly tighten these up, if you have issues with the turbo to intercooler pipe not fitting correctly these may have to be loosened and the housing may need to be turn slightly. 8. Remove the passenger side valve cover. 9. Test fitting the turbo at this time with the down pipe will expose any issues you will have with the a/c accumulator (dryer) on the firewall, the lines can be bent by hand to get the clearance needed. They will most definitely need to be bent out of the way and you may have to remove the accumulator bracket. And slot out the holes so it can be reinstalled. 10. At this time install the 90 degree -4 elbow into the top of the turbo. Make sure you add Teflon tape to the fitting, and install hand tight. 11. Install the -10 drain fitting to the bottom of the turbo using the gasket supplied. At this time go ahead and add the -10 oil drain line to the turbo also and tighten. Be sure not to get anything inside the lines before installing. At this time I also use a paper towel in the other end to make sure nothing gets in the hose during the install. 12. Apply a very thin coat of copper rtv to the rectangle flange on the passenger side header. (so thin you can almost see through it) to the head flange and tack it up with your finger. 13. Install the turbo carefully lowering the drain back line down through the hole you drilled in the frame rail earlier. Make sure you start all bolts and nuts and just tighten finger tight you still want to be able to slide the turbo around. 14. Install the down pipe. Using the 3 inch v-band clamp supplied with the kit. (ON LATE MASTERPOWER TURBO HOUSINGS YOU MAY HAVE TO CLEARANCE THE SIDE OF THE V-BAND CLAMP TO MISS THE STEP IN THE HOUSING GROOVE) 15. At this time you may need to slide the turbo around slightly and turn the down pipe slightly for clearance. 16. Once everything is clear tighten up the turbo and then tighten up the v-band It is important that you do this fast as you can so the silicone does not dry up. 17. Reinstall the Valve cover with new gaskets, make sure you don’t pinch your spark plug wires. (SEE PICTURES BELOW) Hand bend any a/c lines that are close to the turbo, or any of the piping. (See the a/c pictures below. Install the crossover pipe. Making sure the flex is centered directly under the damper pulley. Add a small amount of rtv to the flat surfaces of the v-band flange and use the 2.5 v-band clamps to install. These clamps just need to be hand tight. Do not over tighten the clamp they will break or strip. 18. Install the 02 sensors in the down pipe and extract the factory wiring for the 02 sensors from the factory harness. There should be plenty of wiring without cutting. 19. Install a wideband into the third bung or plug off. 20. Check fuel line clearance. YOU ARE RESPONCEABLE FOR PROPER FUEL LINE CLEARANCE AND ROUTING DO NOT SKIMP HERE. MAKE SURE YOU HAVE AT LEAST 4 INCHES OF CLEARANCE TO ANY RUBBERIZED LINE IF YOU CAN NOT GET 4 INCHES OF CLEARANCE REROUTE YOUR LINES. A/C LINE PICTURES. • Please check for proper clearance to a/c lines See Pictures below. Cold side piping & Intercooler. • If your car is a GT There will be cutting to the inner bumper support and the fog light brackets. Very little to no trimming will be required on the bumper cover it’s self. • If your car is a lx there will be cutting to the inner bumper support, and the outer bumper cover. Take time when trimming the outter cover and take little cuts at a time to get a nice looking fit. Do this after you install the intercooler and piping. • Remove the inner bumper support and fog light bracket. Center the intercooler over the radiator opening and use jack stands to get the correct height. The bottom of the intercooler will be even with the bottom of the radiator support. Make two L brackets going from the top of the intercooler to the top of the radiator support. Use two of the holes already in the radiator support to mount the brackets. Use either 1/16x1 steel strapping or thicker. Or 1/8x1 aluminum strapping. Once the intercooler is installed. Install a 3 inch to 3 inch coupler on the passenger side of the intercooler, using the supplied band clamps. Install a 3 to 2.5 on the driver side , using the supplied band clamps. At this time Install the 3 inch tubing from the intercooler to the throttle body. Install it going through the factory hole in the passenger side inner fender. This hole should not need to be cut bigger unless your motor is in the wrong location. • • Install the 90 degree end on the throttle body and the upper end of the intercooler to throttle body tube. Tighten all clamps only hand tight. Over tightening will cause the clamps to break or strip. • Install the 2.5 to 2.5 coupler on the turbo outlet and install the cold side pipe with the blow off valve flange. After you install make sure the cold side pipe is not resting upon the crossover pipe adjust as necessary to get at least ½ inch clearance. • Install the blow off valve and connect as per instructions supplied with blow off valve. • On Gt models cut the fog light bracing to clear the intercooler and cold side piping. Cut the inner bumper as shown below and install. • Reinstall the bumper cover on the car and trim anything necessary for proper fit. Reinstall inner fenders if removed and reinstall tires. Check everything for clearance and make sure all fasteners are tight. • Install the waste gate and lower down pipe. Hook the waste gate up as per instructions in the gate. • Install the cat back if you bought one through us. If not make a cat back hookup or run a 3.5 pipe into a bullet muffler 3.5 and do a turn down. Metal work Pictures. Mass air • If equipped with mass air you will have to cut the coldside as shown and install inline between the intercooler and throttle body.